1. Introduction

This instruction manual provides essential information for the safe and effective installation, operation, and maintenance of the Cleveland 03506 Contactor. This device is a genuine OEM replacement part, designed to meet the original specifications for reliable performance in various industrial and foodservice applications. Please read this manual thoroughly before attempting any installation or service.

2. Safety Information

WARNING: Electrical shock hazard. Installation and servicing must be performed by qualified personnel only.

- Always disconnect power at the main circuit breaker or fuse panel before installing, servicing, or removing the contactor.

- Follow all local and national electrical codes and regulations.

- Ensure proper grounding of all electrical equipment.

- Use appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses.

- Verify that the voltage and current ratings of the contactor match the application requirements.

3. Product Overview

The Cleveland 03506 Contactor is a 75 Amp, 110V open type electrical switching device. It is designed to control the flow of electrical power to a load, typically a motor or heating element, by opening and closing its contacts. As a genuine OEM replacement part, it ensures compatibility and reliability with existing Cleveland equipment.

Key Features:

- Guaranteed Compatibility: OEM parts fit and function exactly like the original components, ensuring a perfect match for your equipment.

- Higher Quality and Reliability: OEM parts are built to the same quality standards as the original components, reducing the risk of premature failure.

- Safety Assurance: Genuine parts provide peace of mind that your equipment remains safe to use.

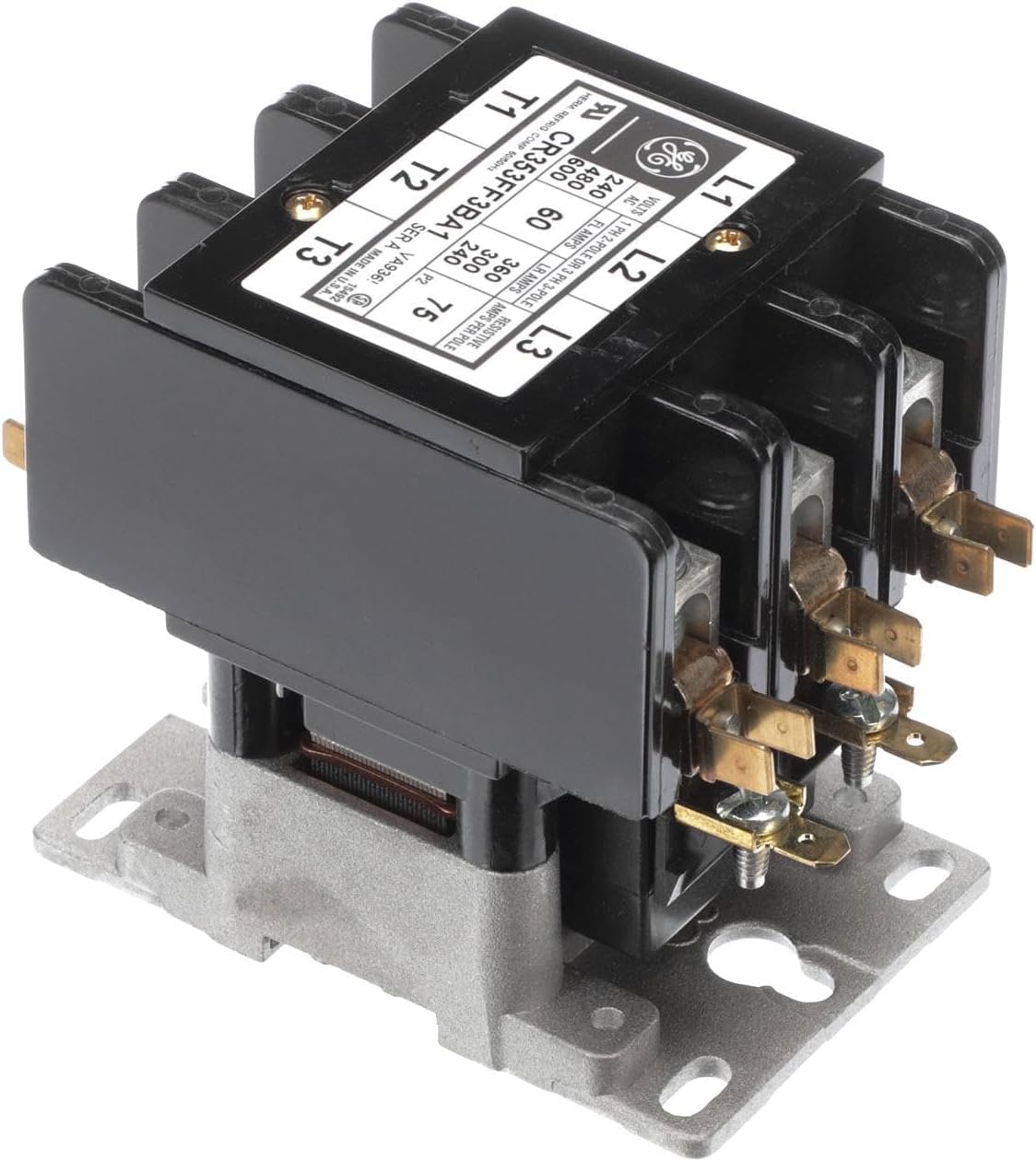

Figure 1: Front-top view of the Cleveland 03506 Contactor, showing the main power terminals L1, L2, L3 and T1, T2, T3, along with the rating label.

Figure 2: Side-front view of the Cleveland 03506 Contactor, highlighting the robust construction and terminal block arrangement.

4. Setup and Installation

Installation of the Cleveland 03506 Contactor should only be performed by a qualified electrician or service technician. Incorrect installation can lead to equipment damage, personal injury, or fire.

Installation Steps:

- Power Disconnection: Ensure all power to the equipment is disconnected and locked out according to safety procedures.

- Mounting: Securely mount the contactor in a suitable enclosure, ensuring adequate ventilation and clearance for wiring. Use appropriate fasteners for the mounting base.

- Wiring Power Circuits: Connect the incoming line voltage to the L1, L2, and L3 terminals. Connect the load (e.g., motor, heating element) to the T1, T2, and T3 terminals. Ensure all connections are tight and secure. Refer to the equipment's wiring diagram for specific connections.

- Wiring Control Circuits: Connect the control voltage (typically 110V for this model) to the coil terminals of the contactor. The coil terminals are usually marked A1 and A2 or similar. Ensure the control circuit wiring is correct as per the system's schematic.

- Verification: Double-check all wiring connections for correctness and tightness. Ensure no loose strands or short circuits are present.

- Power Restoration: Once installation is complete and verified, restore power to the equipment.

Figure 3: Angled view of the Cleveland 03506 Contactor, illustrating the layout of the power terminals and mounting points.

5. Operating Instructions

The Cleveland 03506 Contactor operates by receiving a control signal (110V) to its coil, which then energizes an electromagnet. This electromagnet pulls the movable contacts into connection with the stationary contacts, thereby closing the power circuit and supplying electricity to the connected load.

- When the control circuit is energized, the contactor will close, allowing power to flow to the load.

- When the control circuit is de-energized, the contactor will open, interrupting power to the load.

- Ensure the control circuit is functioning correctly to provide the appropriate signal to the contactor.

6. Maintenance

Regular maintenance helps ensure the longevity and reliable operation of the Cleveland 03506 Contactor. Always disconnect power before performing any maintenance.

- Visual Inspection: Periodically inspect the contactor for signs of wear, damage, discoloration, or loose connections. Check for any accumulation of dust or debris.

- Cleaning: If necessary, gently clean the contactor and its enclosure using a dry, non-conductive brush or compressed air. Do not use liquids.

- Terminal Tightness: Verify that all terminal screws are securely tightened. Loose connections can cause overheating and arcing.

- Contact Condition: While power is disconnected, visually inspect the contacts for excessive pitting or erosion. If contacts are severely worn, the contactor may need replacement.

Figure 4: Another angled view of the Cleveland 03506 Contactor, showing the overall compact design and robust terminals.

7. Troubleshooting

Before troubleshooting, ensure all safety precautions are followed, and power is disconnected.

| Problem | Possible Cause | Solution |

|---|---|---|

| Contactor does not energize (does not pull in) | No control voltage; Open control circuit; Faulty coil | Check control voltage supply; Inspect control circuit wiring and components (e.g., switches, fuses); Test or replace coil. |

| Contactor hums loudly | Loose shading coil; Dirt/debris on magnet faces; Incorrect voltage | Inspect and secure shading coil; Clean magnet faces; Verify correct control voltage. |

| Contactor contacts are pitted or welded | Overload condition; Frequent switching; End of life | Check load for overcurrent; Reduce switching frequency if possible; Replace contactor. |

| Overheating | Loose connections; Overcurrent; Poor ventilation | Tighten all terminals; Verify load current is within ratings; Ensure adequate airflow around contactor. |

8. Specifications

| Specification | Value |

|---|---|

| Brand Name | CLEVELAND |

| Model Number | 03506 |

| Item Weight | 2.6 pounds |

| Product Dimensions | 13 x 11 x 6 inches |

| Voltage | 110 Volts |

| Current Rating | 75 Amp |

| Batteries Required? | No |

| Certification | steam (Note: This may refer to application environment rather than electrical certification. Consult product label for specific electrical certifications.) |

| Date First Available | April 11, 2013 |

9. Warranty Information

Using genuine OEM parts like the Cleveland 03506 Contactor is essential to maintain your equipment's warranty. Non-OEM parts may void existing warranties and could lead to unforeseen compatibility or performance issues. For specific warranty terms and conditions, please refer to the documentation provided with your original Cleveland equipment or contact Cleveland customer support.

10. Support

For technical assistance, replacement parts, or further information regarding the Cleveland 03506 Contactor or other Cleveland products, please contact your authorized Cleveland distributor or a qualified service technician. Always provide the model number (03506) and any relevant serial numbers when seeking support.