1. Introduction

This manual provides comprehensive mechanical service instructions for the Eagle EPT-60 Tube Bending Machine. It is designed to assist technicians and operators with installation, maintenance, and troubleshooting procedures to ensure the optimal performance and longevity of the machine. This edition covers the EPT-60 model and was published in 1990.

The manual contains 137 printed pages detailing various aspects of the machine's mechanical components and systems.

2. Mechanical Installation

Detailed procedures for the mechanical installation of the Eagle EPT-60 Tube Bending Machine are provided within this section. Proper installation is crucial for the machine's safe and efficient operation. Refer to the specific subsections for guidance on positioning, securing, and initial setup of mechanical components.

3. Component Replacement Procedures

This section outlines the steps required for replacing various mechanical components of the EPT-60 machine. Adherence to these procedures is essential for maintaining machine integrity and performance.

3.1. Replacement of Pump

Instructions for the safe and effective replacement of the machine's pump unit are detailed here. This includes steps for depressurizing the system, disconnecting the old pump, and installing the new unit, followed by system priming and testing.

3.2. C Axis Drive Chain

This subsection provides guidance on inspecting, removing, and replacing the C Axis drive chain. Proper tensioning and alignment are critical for the smooth operation of the C Axis.

3.3. Replacement of Spindles in Reaction Arm

Detailed steps for replacing the spindles located within the reaction arm are covered. This procedure ensures the accuracy and stability of the bending process.

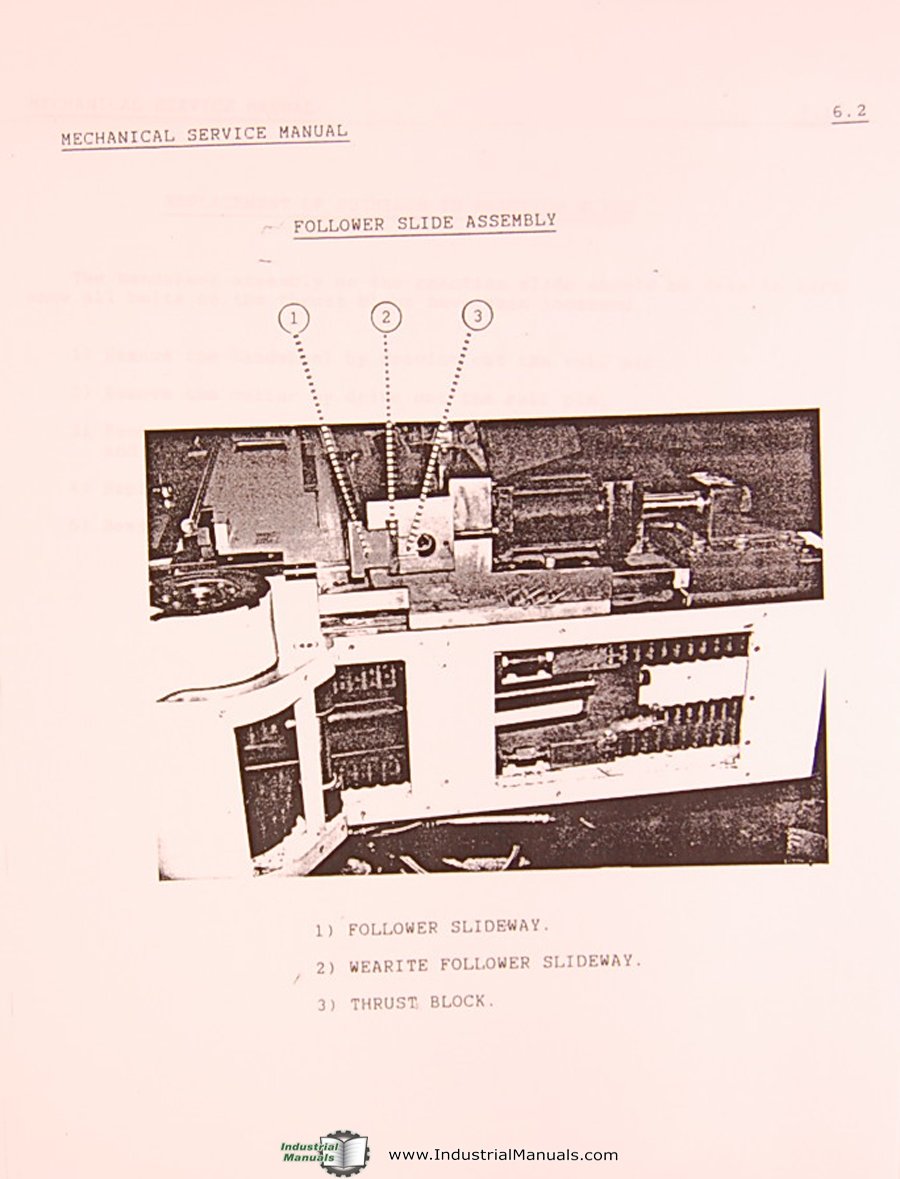

3.4. Replacement of Wearite Follower Slideway

This section describes the process for replacing the Wearite Follower Slideway, a critical component for guiding the tube during bending. Proper replacement ensures smooth operation and prevents damage to the workpiece.

Figure 1: Follower Slide Assembly. This image illustrates the components of the follower slide assembly. Item 1 indicates the Follower Slideway, item 2 points to the Wearite Follower Slideway, and item 3 identifies the Thrust Block. Understanding these components is essential for replacement procedures.

3.5. Replacement of Bushings in Reaction Slide

Instructions for replacing the bushings within the reaction slide are provided. Worn bushings can affect machine precision and should be replaced as per maintenance schedules.

3.6. Mandrel Support Assembly

This subsection details the procedures for servicing and replacing components of the mandrel support assembly, which is vital for internal tube support during bending.

3.7. Clamp Linkage

Guidance on the inspection, adjustment, and replacement of the clamp linkage system is included. Proper functioning of the clamp linkage ensures secure gripping of the tube.

3.8. P.O.B. Unit

Procedures for the maintenance and replacement of the P.O.B. (Plane of Bend) unit are outlined. This unit is crucial for controlling the orientation of the bend.

3.9. Replacement of Y Axis Gears and Rack

This section covers the replacement of the Y Axis gears and rack, which are responsible for the linear movement of the bending head. Accurate replacement ensures precise positioning.

4. Troubleshooting of Machine

This section provides a comprehensive guide to diagnosing and resolving common mechanical issues that may arise with the Eagle EPT-60 Tube Bending Machine. It includes symptom-based troubleshooting tables and recommended corrective actions to minimize downtime and ensure efficient operation.

5. Ordering Spare Parts

Information on how to identify and order genuine spare parts for the EPT-60 machine is provided. This includes part numbering conventions, contact information for authorized distributors, and recommendations for maintaining a critical spare parts inventory.

6. Assembly Drawings

Detailed assembly drawings of various machine components and sub-assemblies are included in this section. These drawings are essential for understanding the machine's construction, aiding in assembly, disassembly, and component identification during service and repair.

7. Vendor Information

This section contains contact details and relevant information for vendors of specialized components or services related to the Eagle EPT-60 Tube Bending Machine. This includes suppliers for hydraulic components, electrical parts, and other specialized materials.

8. Specifications

| Specification | Detail |

|---|---|

| ASIN | B00IHPODT4 |

| Publisher | Eagle |

| Publication Date | January 1, 1990 |

| Language | English |

| Print Length | 137 pages |

9. Warranty and Support

Information regarding product warranty and customer support for the Eagle EPT-60 Tube Bending Machine is not explicitly detailed within this mechanical service manual. For warranty claims or technical support, please refer to your original purchase documentation or contact Eagle directly through the vendor information provided in Section 7.