Introduction

The Beckett T501 Multipurpose Gage is a precision tool designed for accurate adjustments and measurements on various Beckett oil burners. This gage facilitates the correct setup of critical components, ensuring optimal performance and efficiency of your burner system. It is specifically used for setting the electrode gap and position, oil nozzle distance from the burner head, firing pin length, and the gap between the motor and blower wheel on Beckett AF, AFG, AFII, NX, SF, SM, and SR oil burners. This tool replaces the Beckett T500 gage.

Product Overview

Figure 1: Front view of the Beckett T501 Multipurpose Gage. This image displays the various measurement scales and indicators for electrode position, electrode gap, nozzle position, and firing pin gauge.

The T501 gage is constructed from durable metal, featuring clearly marked scales and indicators for precise measurements. It is designed to be a compact and essential tool for burner maintenance.

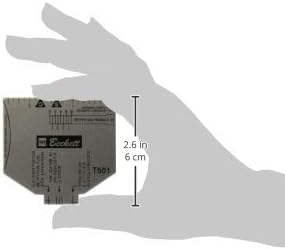

Figure 2: The Beckett T501 Multipurpose Gage held in a hand, illustrating its compact size (approximately 2.6 inches or 6 cm in length) for easy handling and storage.

Setup

Before using the Beckett T501 gage, ensure the oil burner system is powered off and allowed to cool. Always refer to the specific oil burner's service manual for detailed instructions and safety precautions. The gage itself requires no prior setup; it is ready for immediate use upon removal from its packaging.

Operating Instructions

The T501 gage provides multiple measurement functions. Follow the steps below for each specific adjustment:

1. Setting Electrode Gap and Position (AF, AFG, AFII, NX, SF, SM, SR Burners)

- Identify the correct section: Locate the "ELECTRODE POSITION" and "ELECTRODE GAP" markings on the gage. Different burner models may have specific settings.

- Positioning: Place the gage against the burner head or retention head as specified by the burner manufacturer's instructions.

- Adjust Electrode Position: Use the appropriate notch or line on the gage to align the electrode tips to the correct forward position.

- Adjust Electrode Gap: Use the designated slots or markings to set the precise distance between the electrode tips. For example, for NX, AFII HLX6, HLX9, AF2-6, & AF2-9 heads, the electrode position is indicated. For 5/16" FL1 V1 & AFII FBX heads, a different electrode position is indicated.

- Verify: Ensure both position and gap are correctly set before proceeding.

2. Setting Oil Nozzle Distance from Burner Head

- Locate Nozzle Gage: Find the "NOZZLE GAGE" section on the tool.

- Measure Distance: Insert the gage into the burner assembly to measure the distance from the burner head to the oil nozzle. The gage provides markings for 1/8" MIN. and 5/32" MAX. distances.

- Adjust: Adjust the nozzle position as needed to fall within the specified range.

3. Checking Firing Pin Length

- Identify Firing Pin Gage: Use the "AFII FIRING PIN GAUGE" section.

- Measure: Place the gage against the firing pin to check its length against the marked scale (e.g., 0, 1, 2, 3, 4, 5, 6, 7).

- Compare: Ensure the firing pin length meets the manufacturer's specifications for your burner model.

4. Checking Motor to Blower Wheel Gap (AFII Oil Burners)

- Locate Blower Wheel Gage: Find the "AFII BLOWER WHEEL GAUGE" section on the curved edge of the tool.

- Measure Gap: Use this section to measure the gap between the motor and the blower wheel on AFII oil burners.

- Adjust: Adjust the components as necessary to achieve the correct gap according to the burner's specifications.

Note: Always consult the specific service manual for your Beckett oil burner model for precise measurement values and adjustment procedures.

Maintenance

- Cleaning: After each use, wipe the gage with a clean, dry cloth to remove any oil, soot, or debris. Avoid using abrasive cleaners or solvents that could damage the markings.

- Storage: Store the gage in a dry place, away from extreme temperatures and corrosive materials, to prevent rust or damage.

- Inspection: Periodically inspect the gage for any signs of wear, bending, or damage that could affect its accuracy. If the gage is damaged, replace it to ensure precise measurements.

Troubleshooting

The Beckett T501 is a passive measurement tool and typically does not require troubleshooting in the traditional sense. However, if you encounter issues:

- Inaccurate Readings:

- Ensure the gage is clean and free of debris that might interfere with contact points.

- Verify that you are using the correct section of the gage for the specific measurement and burner model.

- Check for any physical damage or bending of the gage that could compromise its accuracy.

- Difficulty in Positioning:

- Confirm that the burner components are correctly assembled and accessible.

- Refer to the burner's service manual for specific instructions on how to access and measure the components.

If you suspect the gage itself is faulty, it is recommended to replace it with a new, undamaged unit.

Specifications

| Feature | Detail |

|---|---|

| Model Number | T501 |

| Brand | Beckett |

| Manufacturer | APR Supply Co. |

| Item Weight | 0.01 ounces |

| Product Dimensions | 1 x 1 x 1 inches (Note: This might be package dimensions; actual gage is approximately 2.6 inches long) |

| Replaces | Beckett T500 Gage |

| Compatibility | Beckett AF, AFG, AFII, NX, SF, SM, SR oil burners |

Warranty and Support

For specific warranty information regarding the Beckett T501 Multipurpose Gage, please refer to the documentation provided with your purchase or contact Beckett customer support directly. General product support and additional resources can be found on the official Beckett Corporation website.

Beckett Corporation: www.beckettcorp.com