Introduction

This manual provides essential information regarding the DB Electrical 410-52551 Starter. It covers product specifications, compatibility, general installation guidelines, operational principles, maintenance recommendations, and troubleshooting tips. Please read this manual thoroughly before installation and operation to ensure proper function and longevity of the unit.

Product Overview

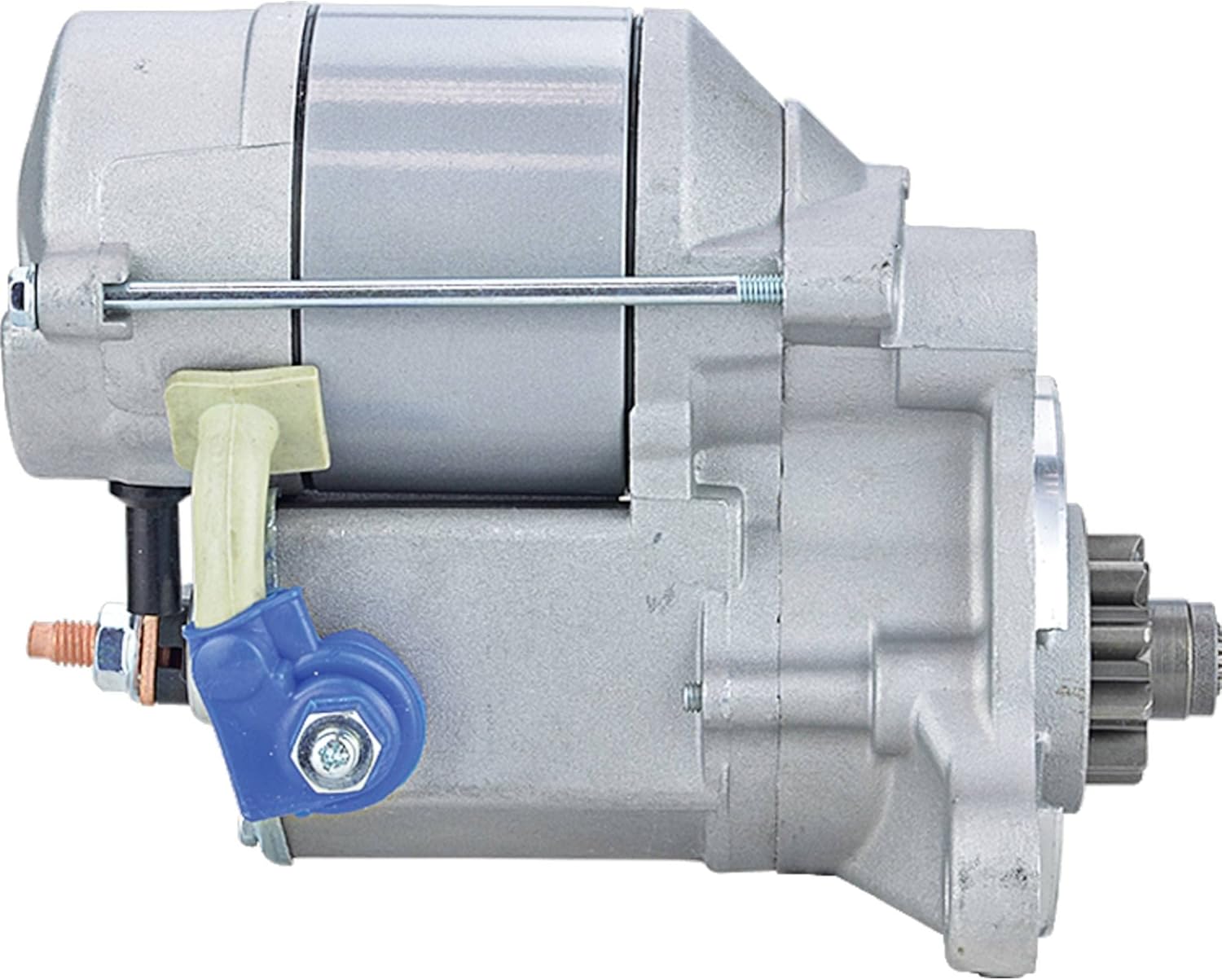

The DB Electrical 410-52551 is a new aftermarket starter designed to meet OEM specifications for various Daewoo Fork Lift Truck and Mitsubishi models. It is a 12-volt, 1.4 KW, 10-tooth OSGR (Offset Gear Reduction) starter with CW (Clockwise) rotation.

Figure 1: Main view of the DB Electrical 410-52551 Starter, showcasing its compact design and key components.

Figure 2: Side view of the starter, highlighting the solenoid and mounting points.

Figure 3: View of the drive gear (bendix) end, showing the 10 teeth for engagement with the flywheel.

Compatibility and OEM Replacement

This starter is compatible with and serves as a direct replacement for the following Daewoo Fork Lift Truck models: G20S, G25S, G30S, GC20S, GC25S, GC30S. It also replaces various OEM part numbers from Arrowhead, Daewoo, Denso, J & N, Lester, Poong Sung, and other reference numbers.

Important: Always verify part fitment with your specific vehicle's requirements before purchasing and installing.

Installation Guidelines

Installation of automotive electrical components, especially starters, requires technical knowledge and specialized tools. It is highly recommended that installation be performed by a qualified mechanic or automotive technician.

Safety Precautions:

- Always disconnect the vehicle's battery (negative terminal first) before beginning any electrical work to prevent accidental shorts or injury.

- Ensure the vehicle is on a stable, level surface and properly secured with wheel chocks and jack stands if lifted.

- Wear appropriate personal protective equipment (PPE), including safety glasses and gloves.

- Refer to your vehicle's specific service manual for detailed, model-specific installation procedures and torque specifications.

General Installation Steps (Consult Vehicle Manual for Specifics):

- Locate the existing starter motor on your vehicle.

- Disconnect all electrical connections from the old starter (battery cable, solenoid wire).

- Remove the mounting bolts securing the old starter to the engine or transmission bell housing.

- Carefully remove the old starter. Note its orientation for proper installation of the new unit.

- Install the new DB Electrical 410-52551 starter, ensuring it seats correctly.

- Secure the new starter with the mounting bolts, tightening them to the manufacturer's specified torque.

- Reconnect all electrical connections to the new starter, ensuring they are clean and tight.

- Reconnect the vehicle's battery (positive terminal first, then negative).

- Test the starter operation.

Operation

The starter motor is a critical component of your vehicle's engine starting system. When the ignition key is turned to the "start" position, electrical current flows from the battery to the starter motor. The starter motor then engages a small gear (bendix) with the engine's flywheel, rotating the crankshaft to initiate the combustion process. Once the engine starts, the bendix gear disengages from the flywheel, and the starter motor ceases operation.

This DB Electrical starter is designed for reliable and efficient engine cranking, providing the necessary torque to start your Daewoo forklift or compatible Mitsubishi vehicle.

Understanding Starter Operation

Video 1: An informational video from DB Electrical demonstrating the function and components of a starter motor and bendix drive. This video provides a visual aid to understand how these parts work together to start an engine.

Maintenance

While the DB Electrical 410-52551 starter is a sealed unit and requires no internal maintenance, regular inspection of related components can help ensure its longevity and reliable performance.

- Battery Condition: Ensure your vehicle's battery is in good condition and fully charged. A weak battery can put excessive strain on the starter.

- Electrical Connections: Periodically check all electrical connections to the starter (battery cable, solenoid wire) for cleanliness, corrosion, and tightness. Loose or corroded connections can impede current flow and affect starter performance.

- Wiring Integrity: Inspect the wiring leading to and from the starter for any signs of fraying, damage, or insulation breakdown.

- Mounting Security: Ensure the starter is securely mounted to the engine/transmission. Loose mounting can lead to misalignment and premature wear.

- Avoid Excessive Cranking: Do not crank the engine for extended periods (more than 10-15 seconds) without allowing the starter to cool down. Excessive cranking can overheat and damage the starter.

Troubleshooting

If you experience issues with your vehicle's starting system, consider the following common troubleshooting steps. For complex issues, professional diagnosis is recommended.

- Engine Does Not Crank or Cranks Slowly:

- Check battery charge and terminals. A weak battery is a common cause.

- Inspect battery cables and starter connections for corrosion or looseness.

- Listen for a single click from the starter solenoid when turning the key. This might indicate a faulty solenoid or insufficient power reaching it.

- Starter Spins But Engine Does Not Crank:

- This often indicates a problem with the starter's bendix drive (overrunning clutch) not engaging the flywheel.

- The flywheel ring gear might also be damaged.

- Grinding Noise During Cranking:

- This could be due to worn starter gear teeth, worn flywheel teeth, or improper starter alignment.

If these basic checks do not resolve the issue, or if you are unsure about performing these checks, it is advisable to consult a certified automotive technician for a thorough diagnosis and repair.

Specifications

| Specification | Value |

|---|---|

| Unit Type | Starter |

| Voltage | 12 Volts |

| Rotation | CW (Clockwise) |

| Teeth | 10 |

| KW | 1.4 KW |

| Starter Type | OSGR (Offset Gear Reduction) |

| Item Weight | 8.82 pounds |

| Product Dimensions | 9 x 5.5 x 5.8 inches |

| Manufacturer Part Number | 410-52551 |

| OEM Part Numbers Replaced | 03101-3150, A213980, D141164, D141291, 228000-5060, 228000-5061, SND0692, 410-52551, 410-52266, 17379A, 19919, 190-20134 |

Warranty and Support

DB Electrical stands behind the quality of its products. This starter comes with a 1-year warranty from the date of purchase. This warranty covers defects in materials and workmanship under normal use.

If you encounter any issues with your starter within the warranty period, or if it does not perform as expected after proper installation, please contact DB Electrical customer support for assistance. They are committed to ensuring customer satisfaction and will facilitate a replacement if necessary.

For support inquiries, please refer to the contact information provided on the official DB Electrical website or through your original point of purchase.