1. Introduction

This manual provides essential information for the proper installation, operation, and maintenance of your DB Electrical AND0253 Alternator. This alternator is designed to meet OEM specifications for Mercruiser and Mercury Marine applications. Please read these instructions carefully before proceeding with installation or use to ensure optimal performance and safety.

2. Product Overview

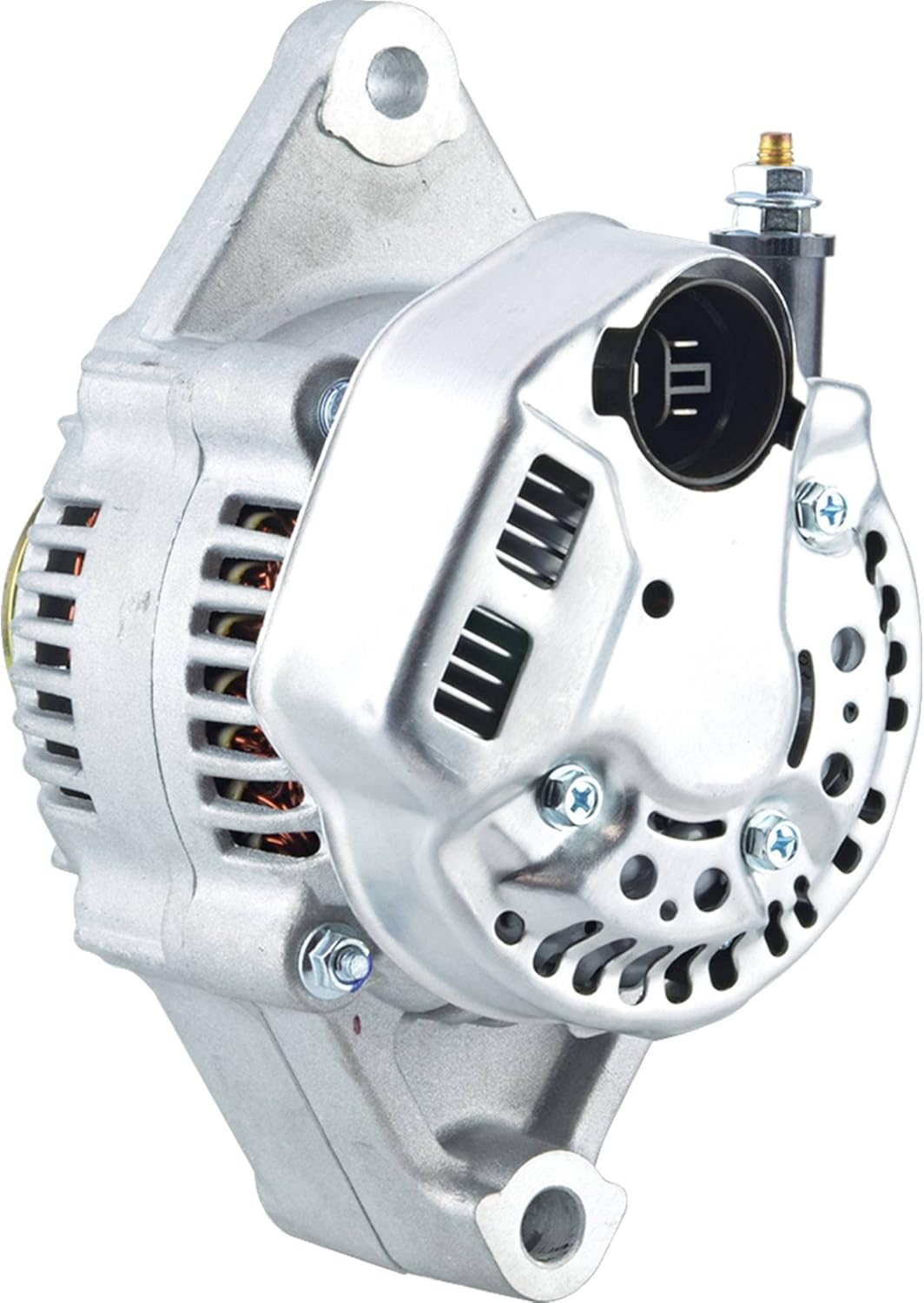

The DB Electrical AND0253 is a 12-volt, 60-amp alternator with a clockwise rotation and an S4 pulley class. It features an internal regulator (IR) and internal fan (IF) design. Below are various views of the alternator to help identify its components.

Figure 2.1: Front angled view of the alternator, showing the pulley and mounting points.

Figure 2.2: Side view of the alternator, highlighting the cooling fins and housing.

Figure 2.3: Rear angled view, displaying the B+ terminal, S terminal, IG terminal, and L terminal connections.

Figure 2.4: Another rear angled perspective, providing a clearer view of the regulator housing.

Figure 2.5: Detailed rear view, emphasizing the ventilation slots and mounting points.

Figure 2.6: Front view, clearly showing the 4-groove pulley and its attachment nut.

3. Specifications

| Specification | Detail |

|---|---|

| Unit Type | Alternator |

| Voltage | 12 Volts |

| Amperage | 60 Amps |

| Rotation | Clockwise (CW) |

| Clock Position | 12 O'Clock |

| Pulley Class | S4 (4-Groove Pulley, 50mm OD) |

| Regulator Type | Internal Regulator (IR) |

| Fan Type | Internal Fan (IF) |

| Mounting Ear 1 Hole | 10.3mm Unthreaded |

| Mounting Ear 2 Hole | 10.2mm Unthreaded |

| Mounting Ear 1 Thickness | 15.6mm |

| Mounting Ear 2 Thickness | 58mm |

| B+ Terminal | M6-1.0 |

| S Terminal | Spade |

| IG Terminal | Spade |

| L Terminal | Spade |

| Weight | 7.74 pounds |

| Product Dimensions | 5.46 x 5.46 x 5.46 inches |

4. Compatibility

This DB Electrical AND0253 Alternator is compatible with the following Mercruiser and Mercury Marine models:

- MERCRUISER: Model 500 EFI (1999)

- MERCURY MARINE:

- 135.0HP / V-135 - SN 0G590000 Thru 0G760299 (All)

- 135CXL OS Optimax (1998)

- 135L Optimax (1998)

- 135XL Optimax (1998)

- 150.0HP / V-150 - SN 0G590000 Thru 0G760299 (All)

- 150CXL OS Optimax (1998)

- 150L Optimax (1998)

- 150XL OS Optimax (1998)

Replaces OEM Numbers:

- ARROWHEAD: AND0253

- DENSO: 101211-3460

- EMP PARTS: 4-6844

- J & N: 400-52346

- LESTER: 12347

- MERCURY MARINE: 834832, 834832T2

Important: Always verify the part fits your specific application before purchase and installation. Refer to your engine's service manual for exact part numbers and procedures.

5. Installation Guidelines

Warning: Improper installation can lead to serious injury or damage to your vessel. It is highly recommended that installation be performed by a qualified marine technician.

5.1. Safety Precautions

- Always disconnect the battery's negative (-) terminal first, then the positive (+) terminal, before beginning any electrical work.

- Wear appropriate personal protective equipment, including safety glasses and gloves.

- Ensure the engine is cool before working on it.

- Keep all tools and loose clothing away from moving parts.

5.2. Removal of Old Alternator

- Disconnect the battery.

- Label and disconnect all electrical connections from the old alternator (B+, S, IG, L terminals).

- Loosen the tensioner and remove the drive belt from the alternator pulley.

- Remove the mounting bolts and carefully detach the old alternator from the engine bracket.

5.3. Installation of New Alternator

- Position the new DB Electrical AND0253 Alternator onto the engine bracket.

- Install the mounting bolts and tighten them to the manufacturer's specified torque. Do not overtighten.

- Install the drive belt onto the alternator pulley and adjust the belt tension according to your engine's service manual.

- Reconnect all electrical connections to the corresponding terminals (B+, S, IG, L). Ensure connections are clean and secure.

- Reconnect the battery, positive (+) terminal first, then the negative (-) terminal.

5.4. Post-Installation Check

- Start the engine and observe the charging system indicator light. It should turn off shortly after the engine starts.

- Using a voltmeter, check the battery voltage with the engine running. It should typically read between 13.8 and 14.8 volts.

- Listen for any unusual noises from the alternator or belt.

6. Operation

The alternator's primary function is to generate electrical power to recharge the vessel's battery and supply power to the electrical systems while the engine is running. It converts mechanical energy from the engine's crankshaft (via the drive belt) into electrical energy. The internal regulator maintains a consistent output voltage to prevent overcharging or undercharging the battery.

7. Maintenance

Regular maintenance helps ensure the longevity and reliable operation of your alternator:

- Belt Inspection: Periodically check the drive belt for cracks, fraying, or excessive wear. Ensure it has the correct tension as specified in your engine's service manual. A loose belt can cause insufficient charging, while an overly tight belt can damage bearings.

- Electrical Connections: Inspect all wiring connections to the alternator for corrosion, looseness, or damage. Clean any corrosion and ensure all terminals are securely fastened.

- Cleanliness: Keep the alternator free from excessive dirt, oil, and debris. A buildup of contaminants can hinder cooling and affect performance.

- Battery Health: Ensure your battery is in good condition. A failing battery can put undue strain on the alternator.

8. Troubleshooting

If you experience issues with your charging system, consider the following common problems and potential solutions:

| Symptom | Possible Cause | Action |

|---|---|---|

| Battery not charging / Low voltage | Loose or worn drive belt Corroded or loose electrical connections Faulty battery Internal alternator failure | Check/adjust belt tension Clean and tighten connections Test battery health Consult a marine technician for alternator testing |

| Charging system warning light on | Alternator not charging Wiring issue Faulty warning light circuit | Check charging voltage Inspect wiring for damage Professional diagnosis recommended |

| Unusual noise from alternator | Worn bearings Loose mounting bolts Loose or misaligned belt | Inspect for play in pulley Tighten mounting bolts Check belt condition and alignment |

| Overcharging (high voltage) | Faulty voltage regulator | Requires professional diagnosis and replacement of alternator or regulator |

If troubleshooting steps do not resolve the issue, it is recommended to seek assistance from a certified marine mechanic.

9. Warranty and Support

9.1. Warranty Information

This DB Electrical alternator comes with a 1-year warranty from the date of purchase. This warranty covers defects in materials and workmanship under normal use. If the product fails within one year of your order, please contact DB Electrical for a replacement. The warranty does not cover damage due to improper installation, misuse, neglect, or unauthorized modifications.

9.2. Customer Support

For technical assistance, warranty claims, or any questions regarding your DB Electrical AND0253 Alternator, please refer to the contact information provided with your purchase or visit the official DB Electrical website. When contacting support, please have your product model number (AND0253) and purchase details readily available.