1. Introduction

This manual provides essential information for the proper use, setup, and maintenance of your 3M Infrared Welding Flip-Up Safety Glasses, Model 40427-00000-10. These lenses are designed to fit over most metal protective eyewear frames, offering protection against glare, UV, and certain infrared radiation during specific industrial and occupational tasks. Adherence to these instructions is crucial for safety and optimal performance.

2. Important Safety Information

WARNING: Failure to follow these instructions and warnings may result in serious injury, sickness, or death.

2.1 Intended Use

- These safety glasses are intended for industrial/occupational use only. They are not for consumer sale or use.

- Recommended for welders, welders' helpers, and workers in the vicinity of welding operations, metal melting, or furnace viewing.

- Note: If actively arc welding, a welding helmet or filter with adequate IR protection must be worn. These flip-up lenses alone do not provide sufficient protection for direct arc welding.

2.2 General Safety Guidelines

- Always inspect lenses for damage before each use. Discard if scratched, pitted, or otherwise compromised.

- Ensure the lenses are clean and free from obstructions that could impair vision.

- These lenses meet the High Impact Requirements of CSA Z94.3-2007 and ANSI Z87.1-2020.

- Consult your on-site safety professional or industrial hygienist for product selection and use specific to your workplace.

3. Product Features

The 3M Infrared Welding Flip-Up Safety Glasses offer several features designed for user convenience and protection:

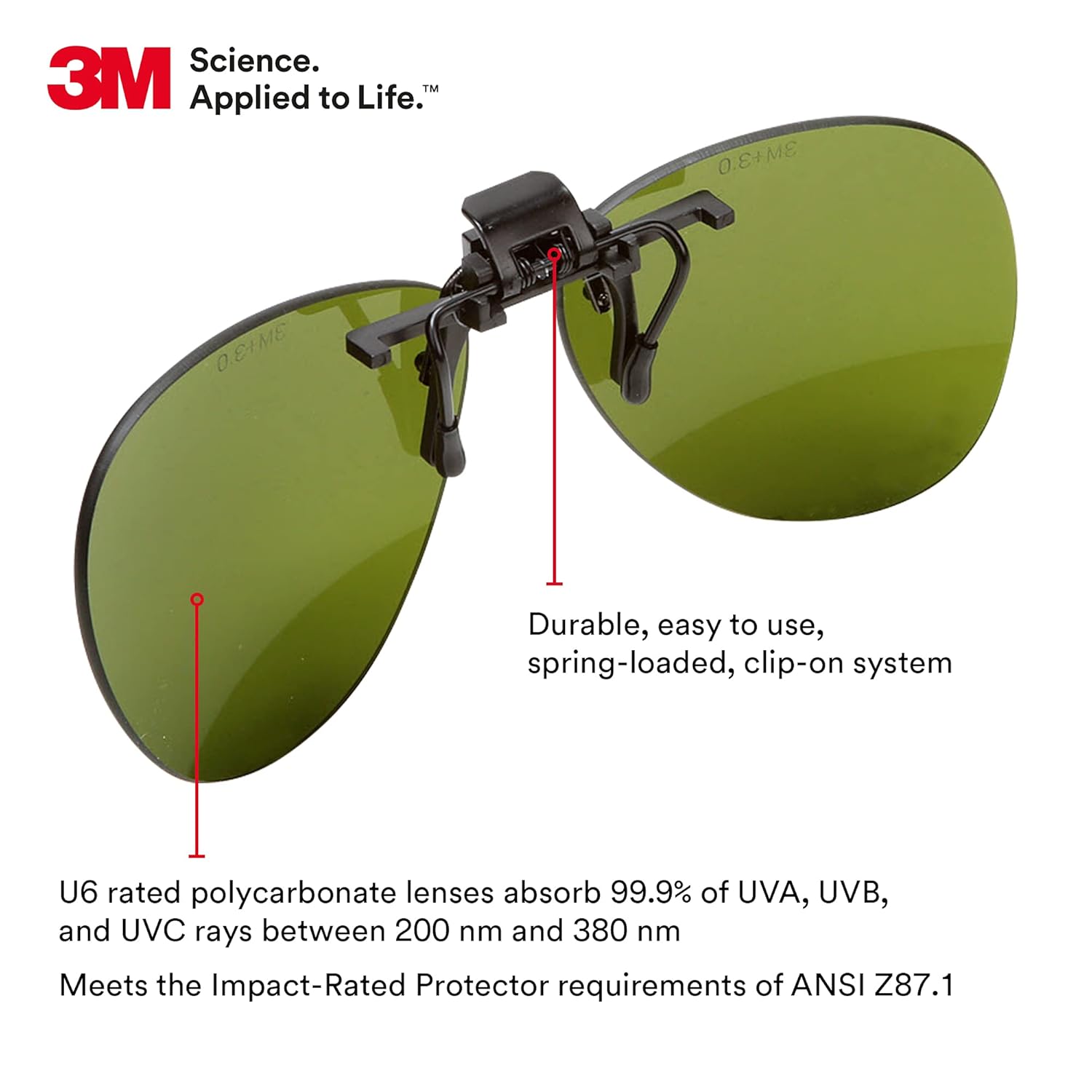

- Flip-Up Design: Features a durable, easy-to-use, spring-loaded clip-on system for quick adjustment.

- Fits Over Glasses: Specifically designed to fit over most standard metal protective eyewear frames.

- Infrared Shade 3 Lenses: Provides protection against glare, UV, and certain infrared radiation.

- Polycarbonate Lenses: Absorb 99.9% of UVA, UVB, and UVC rays between 200 nm and 380 nm.

- ANSI Z87.1-2020 Compliant: Meets high impact requirements for eye and face protection.

Image 1: Overview of 3M Flip-Up Safety Glasses highlighting the durable clip-on system and U6 rated polycarbonate lenses that absorb 99.9% of UV rays.

4. Setup and Installation

4.1 Attaching the Flip-Up Lenses

- Ensure your primary protective eyewear (if applicable) is clean and undamaged.

- Gently open the spring-loaded clip on the 3M Flip-Up Safety Glasses.

- Position the clip over the bridge of your primary eyewear frame.

- Release the clip, ensuring it securely grips the frame without obstructing your vision or causing discomfort.

- Verify that the flip-up lenses are stable and can be easily raised and lowered.

Image 2: The 3M Flip-Up Safety Glasses shown attached to a pair of existing eyewear, illustrating the 'fits over glasses' design.

5. Operating Instructions

5.1 Using the Lenses

- During Operations: When performing tasks such as welding vicinity work, metal melting, or furnace viewing, ensure the flip-up lenses are in the down position, covering your eyes.

- Intermittent Tasks: For tasks requiring clear, unshaded vision, gently flip the lenses up. The spring-loaded mechanism will hold them in the raised position.

- Environmental Awareness: Always be aware of your surroundings. The Shade 3 tint reduces brightness, which may affect perception in dimly lit areas.

Image 3: Front view of the 3M Infrared Welding Flip-Up Safety Glasses, demonstrating the lens appearance.

6. Maintenance and Care

6.1 Cleaning

- Clean lenses regularly with a soft, lint-free cloth and a mild soap and water solution.

- Avoid abrasive cleaners, solvents, or paper towels, as these can scratch or damage the lens coating.

- Rinse thoroughly with clean water and air dry or gently blot with a clean, soft cloth.

6.2 Storage

- Store the safety glasses in a clean, dry place away from direct sunlight and extreme temperatures.

- Use a protective case to prevent scratches and damage when not in use.

7. Troubleshooting

- Lenses not fitting securely: Ensure the clip is properly aligned with the bridge of your primary eyewear. Adjust position until a firm grip is achieved. If the clip is damaged, discontinue use.

- Reduced visibility: Check lenses for dirt, smudges, or scratches. Clean as per Section 6.1. If lenses are heavily scratched or pitted, replace the unit.

- Discomfort: Ensure the clip is not pinching or applying excessive pressure to your primary eyewear or nose bridge. Adjust position for comfort.

8. Technical Specifications

| Specification | Detail |

|---|---|

| Model Number | 40427-00000-10 |

| Brand | 3M |

| Lens Shade | Infrared Shade 3 |

| Lens Material | Polycarbonate |

| UV Protection | Absorbs 99.9% UVA, UVB, UVC (200-380 nm) |

| Impact Rating | Meets ANSI Z87.1-2020 and CSA Z94.3-2007 High Impact Requirements |

| Frame Material | Metal (clip mechanism) |

| Package Dimensions | 10.39 x 7.4 x 0.87 inches |

| Item Weight | 1.12 ounces |

9. Warranty and Support

For detailed warranty information and product support, please refer to the official 3M website or contact 3M customer service. As stated in the legal disclaimer, 3M industrial and occupational products are intended for trained industrial and occupational customers for workplace use. Misuse may result in injury or property damage. For assistance with product selection and use, consult your on-site safety professional or industrial hygienist.

Manufacturer: 3M

Date First Available: February 1, 2012