1. Introduction

This manual provides essential information for the proper handling, installation, operation, and maintenance of the Timken HH224332 Tapered Roller Bearing. This single cone (inner ring) is designed to be paired with a compatible cup (outer ring, sold separately) to form a complete single tapered roller bearing unit. It is engineered to support both radial and axial loads in various high-load, moderate-speed applications.

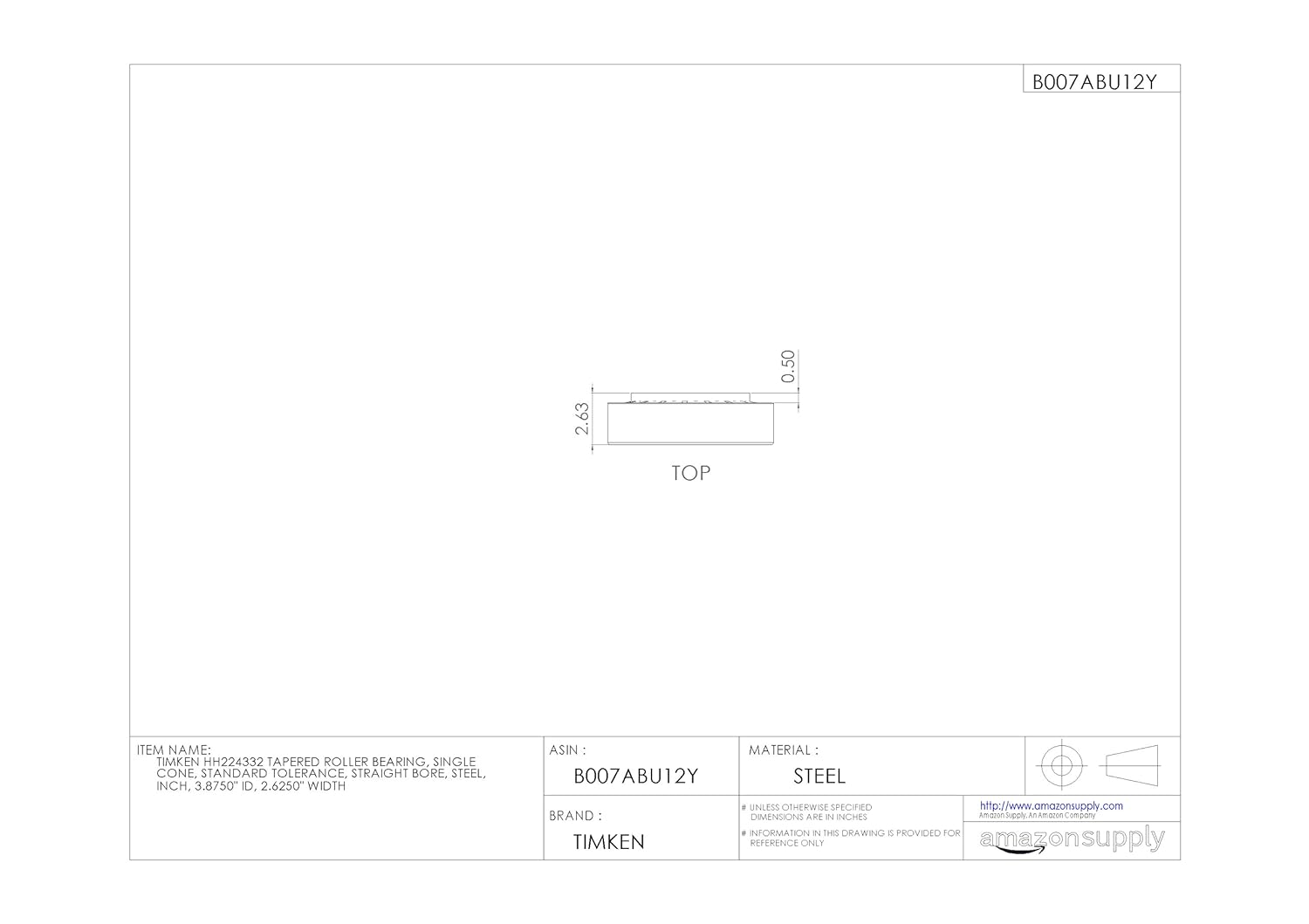

Figure 1: Timken HH224332 Tapered Roller Bearing, single cone. This image shows the complete single cone assembly with its rollers and inner ring.

Key Features:

- Single cone (inner ring) for connecting to compatible cups (outer rings, sold separately) to form a complete single tapered roller bearing.

- Supports both radial and axial loads between a rotating and non-rotating member.

- Operating temperatures range from -54 to 120 degrees C (-65 to 250 degrees F).

- Stamped steel cage evenly spaces rollers for reduced friction, vibration, and noise.

- Open configuration for lubrication applied in place.

2. Setup and Installation

Proper installation is crucial for the optimal performance and longevity of your Timken tapered roller bearing. This bearing is designed to be mounted in opposing pairs on a shaft to evenly distribute loads. Always ensure the mating cup (outer ring) is compatible with this HH224332 cone.

Pre-Installation Steps:

- Inspection: Carefully inspect the bearing cone and the mating cup for any signs of damage, corrosion, or manufacturing defects before installation.

- Cleaning: Ensure all components, including the shaft and housing, are thoroughly clean and free of dirt, debris, or old lubricant.

- Lubrication: Apply a thin film of the recommended lubricant to the bearing surfaces immediately prior to installation to prevent corrosion and aid in assembly.

Mounting Considerations:

Tapered roller bearings require precise mounting to achieve proper internal clearance and load distribution. Refer to industry standards such as ISO 355 and ABMA standard 19.2 for detailed mounting procedures. The open design of this cone allows for accurate adjustments during installation.

Figure 2: Front view technical drawing of the HH224332 bearing, showing internal diameter and overall dimensions.

Figure 3: Side view technical drawing of the HH224332 bearing, illustrating its profile and width.

Figure 4: Top view technical drawing of the HH224332 bearing, showing the tapered roller arrangement.

3. Operating Guidelines

The Timken HH224332 tapered roller bearing is designed for reliable performance in demanding environments. Its robust construction from high-alloy steel ensures durability, heat tolerance, and resistance to deformity under heavy loads.

Load Capacity:

This bearing effectively supports both radial loads (perpendicular to the shaft) and axial loads (parallel to the shaft). When assembled with a compatible cup, the tapered design allows for efficient distribution of combined loads, making it suitable for applications such as automotive axle systems and conveyor systems.

Temperature Range:

The bearing is designed to operate within a temperature range of -54°C to 120°C (-65°F to 250°F). Exceeding these temperatures can compromise bearing performance and lifespan. Ensure adequate cooling and lubrication are maintained within the operating environment.

Speed Considerations:

This bearing is optimized for moderate-speed applications. While robust, continuous operation at excessively high speeds or under extreme loads beyond its design limits can lead to premature wear or failure. Consult Timken's technical data for specific speed ratings for your application.

4. Maintenance

Regular maintenance is essential to maximize the service life and ensure the reliable operation of your Timken HH224332 bearing. The open design facilitates lubrication and inspection.

Lubrication:

This bearing is supplied as an open unit and requires lubrication in place. Periodic reapplication of lubrication is necessary based on the specific application, operating conditions, and environmental factors. Use a high-quality lubricant recommended for tapered roller bearings and the operating temperature range. Proper lubrication reduces friction, dissipates heat, and prevents corrosion.

Inspection:

Periodically inspect the bearing for signs of wear, such as pitting, spalling, or discoloration. Check for unusual noise or vibration during operation, which can indicate a need for maintenance or replacement. Ensure the stamped steel cage is intact and effectively spacing the rollers.

Cleaning:

If the bearing needs to be removed for inspection or maintenance, clean it thoroughly with a suitable solvent and allow it to dry completely before re-lubricating and re-installing.

5. Troubleshooting

This section addresses common issues that may arise during the operation of your Timken HH224332 tapered roller bearing.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Excessive Noise or Vibration |

|

|

| Overheating |

|

|

| Premature Wear |

|

|

If issues persist after attempting these solutions, it is recommended to consult a qualified technician or contact Timken customer support for further assistance.

6. Specifications

The following table provides key specifications for the Timken HH224332 Tapered Roller Bearing.

| Specification | Value |

|---|---|

| Model Number | HH224332 |

| Brand | TIMKEN |

| ASIN | B007ABU12Y |

| Item Weight | 19.51 Pounds (8.85 Kilograms) |

| Material | Alloy Steel |

| Bearing Type | Tapered Roller Bearing (Single Cone) |

| Inner Diameter (ID) | 3.8750 inches |

| Width | 2.6250 inches |

| Operating Temperature Range | -54 to 120 degrees C (-65 to 250 degrees F) |

| Standards Met | ISO 355, ABMA standard 19.2, ISO 492, ISO 720 |

7. Warranty and Support

For specific warranty information regarding the Timken HH224332 Tapered Roller Bearing, please refer to the documentation provided at the time of purchase or visit the official Timken website. Warranty terms typically cover manufacturing defects and material flaws under normal use and service.

Customer Support:

If you require technical assistance, have questions about installation, or need to report an issue, please contact Timken customer support directly. Their official website usually provides contact details, technical resources, and a network of distributors.

Timken Company Contact Information:

Please visit www.timken.com for the most current contact details and support resources.