Introduction

This document provides comprehensive instructions for the proper installation, operation, and maintenance of your Flowmaster 817200 American Thunder Crossmember-Back Exhaust Kit. This system is specifically designed for 1968-1972 GM A-Body V8 vehicles, offering a 3-inch stainless steel construction for durability and performance. Key features include Super 40 Series Performance Mufflers for a deep, powerful sound, an H-pipe crossover for maximum power, and mandrel-bent 16-gauge stainless steel tubing for optimal exhaust flow.

Safety Information

CALIFORNIA WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

Always wear appropriate personal protective equipment, including safety glasses and gloves, when working with automotive components. Ensure the vehicle is securely supported on jack stands or a lift before beginning any installation. Allow the exhaust system to cool completely before handling. Exercise caution when cutting or welding, and ensure proper ventilation.

Package Contents

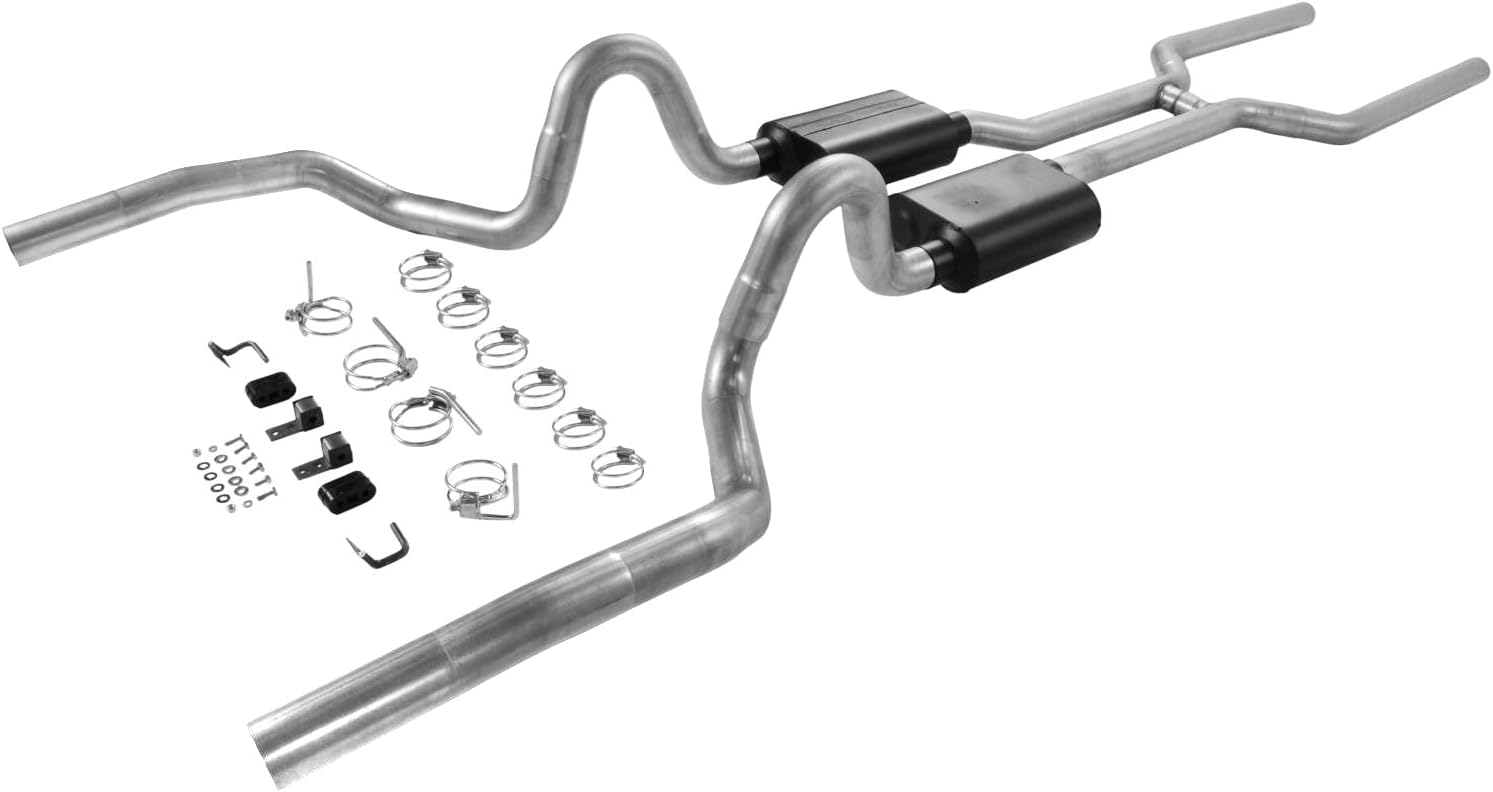

Verify that all components are present before beginning installation:

- Flowmaster 817200 American Thunder 3.00" Header-Back Exhaust System for GM A-Body V8 Engine

- Hangers and Hardware for Installation

Refer to the image below for a visual representation of the kit components.

Setup and Installation

This exhaust system is designed for a bolt-on installation. While designed for ease of fit, professional installation is recommended. Always consult a qualified mechanic if you are unsure about any step.

Tools and Materials (Not Included):

- Wrenches/Sockets

- Cutting Tool (if removing old exhaust)

- Penetrating Oil

- Torque Wrench

- Safety Glasses and Gloves

Installation Steps:

- Preparation: Secure the vehicle on a lift or jack stands. Allow the existing exhaust system to cool completely.

- Removal of Old System: Carefully remove the existing exhaust system, starting from the rear. Use penetrating oil on stubborn bolts and hangers.

- Component Layout: Lay out all new Flowmaster components to familiarize yourself with the system.

- Initial Fitment: Begin installing the new system from the front (header-back), loosely fitting all pipes, mufflers, and hangers. Do not fully tighten any clamps or bolts at this stage.

- Alignment: Ensure proper alignment and clearance around all vehicle components, including the crossmember, suspension, and fuel lines. Adjust as necessary. Note: Some aftermarket crossmembers may require modification for optimal fitment.

- Final Tightening: Once the system is properly aligned and has adequate clearance, progressively tighten all clamps and bolts to manufacturer specifications.

- Final Inspection: Start the vehicle and check for any exhaust leaks or rattles. Ensure all connections are secure.

Operating Characteristics

The Flowmaster 817200 American Thunder exhaust system is engineered to deliver a moderate to aggressive interior and exterior tone. This system is designed for enthusiasts who desire a noticeable and powerful exhaust sound. The Super 40 Series Performance Mufflers contribute to this distinct sound profile, while the H-pipe crossover enhances exhaust scavenging for improved engine performance and throttle response.

For a visual overview of Flowmaster's manufacturing process and product application, please watch the video below:

Maintenance

The Flowmaster 817200 exhaust system is constructed from stainless steel, offering excellent corrosion resistance and durability. Regular maintenance is minimal but can extend the life and appearance of your system:

- Regular Cleaning: Periodically clean the exhaust tips and visible sections of the piping with a mild automotive cleaner to remove road grime and maintain shine.

- Inspection: Annually inspect all hangers, clamps, and welds for signs of wear, damage, or looseness. Tighten any loose connections.

- Corrosion Check: While stainless steel is highly resistant, inspect for any signs of unusual corrosion, especially in areas exposed to road salt or harsh chemicals.

Troubleshooting

If you encounter issues with your Flowmaster exhaust system, consider the following common problems and solutions:

- Rattling or Vibrations: Check all hangers and mounting points. Ensure the exhaust system has adequate clearance from the chassis, suspension, and other components. Loose clamps can also cause rattles.

- Exhaust Leaks: Listen for hissing sounds, especially when the engine is cold. Inspect all connections and welds for signs of leaks. Tighten clamps or replace gaskets as needed.

- Poor Fitment: While designed for specific vehicles, variations in vehicle manufacturing or the presence of aftermarket components (e.g., transmission crossmembers) can sometimes affect fitment. If significant fitment issues arise, professional adjustment or modification may be necessary.

- Unusual Noise: Ensure all components are securely fastened and not contacting other parts of the vehicle. Check for internal muffler damage if a sudden change in sound occurs.

Specifications

| Feature | Detail |

|---|---|

| Model | 817200 |

| Brand | Flowmaster |

| Material | Stainless Steel |

| Installation Type | Bolt-On |

| Tubing Diameter | 3 Inch |

| System Type | Crossmember-Back True Dual Exhaust System |

| Muffler Series | Super 40 Series |

| Crossover Type | H-pipe |

| Vehicle Compatibility | 1968-1972 GM A-Body V8 |

| Item Weight | 75.2 pounds |

| UPC | 700042025558 |

Warranty and Support

For specific warranty information or technical support regarding your Flowmaster 817200 American Thunder Exhaust Kit, please contact Flowmaster customer service directly. You can often find contact details on the official Flowmaster website or through your product retailer.

Visit the official Flowmaster Store for more products and information: Flowmaster Store