1. Introduction

Thank you for choosing the Yato YT-1707 Bottle Jack. This hydraulic bottle jack is designed for lifting vehicles and other heavy objects in automotive repair, construction, and general workshop environments. It features a robust construction and a lifting capacity of 20 tonnes, making it suitable for demanding tasks. Please read this manual thoroughly before operation to ensure safe and efficient use of the product.

Figure 1: The Yato YT-1707 Bottle Jack. This image shows the black, cylindrical hydraulic jack with its lifting saddle, pump handle socket, and base. The YATO logo is visible on the side.

2. Safety Information

Always prioritize safety when operating the Yato YT-1707 Bottle Jack. Failure to follow these instructions may result in property damage, personal injury, or death.

- Read the entire manual: Understand all instructions and warnings before use.

- Capacity: Never exceed the rated lifting capacity of 20 tonnes.

- Stable Surface: Always operate the jack on a hard, level, and stable surface. Avoid soft ground or uneven terrain.

- Support Stands: After lifting, always support the load with appropriate jack stands before working underneath. The jack is a lifting device only, not a support device.

- Center the Load: Ensure the load is centered on the jack's saddle to prevent slipping.

- Clear Area: Keep hands, feet, and other body parts clear of moving parts and the load during lifting and lowering.

- Inspect Before Use: Check the jack for any damage, leaks, or loose parts before each use. Do not use if damaged.

- Proper Storage: Store the jack in a clean, dry place, fully lowered.

- Maintenance: Perform regular maintenance as described in this manual.

3. Setup

3.1 Unpacking and Initial Inspection

- Carefully remove the jack from its packaging.

- Inspect the jack for any signs of shipping damage, such as dents, leaks, or bent components. If damage is found, do not use the jack and contact your supplier.

- Ensure all components are present, including the pump handle.

3.2 Preparing the Jack for Use

- Bleeding the Hydraulic System: Before first use, or if the jack has been stored for a long time, it may be necessary to bleed air from the hydraulic system.

- Turn the release valve counter-clockwise to open it.

- Pump the handle several times to force air out.

- Turn the release valve clockwise to close it.

- Check Oil Level: Ensure the hydraulic oil level is correct. Refer to the Maintenance section for details.

- Positioning: Place the jack on a firm, level surface directly under the lifting point of the load.

4. Operating Instructions

4.1 Lifting the Load

- Ensure the jack is on a stable, level surface and the load is properly positioned on the saddle.

- Close the release valve firmly by turning it clockwise until it is tight. Do not overtighten.

- Insert the pump handle into the handle socket.

- Pump the handle steadily up and down. The jack's ram will extend, lifting the load.

- Lift the load only to the necessary height. Do not extend the ram beyond its maximum extension mark.

- Once the desired height is reached, immediately place appropriate jack stands under the load for support. The jack is not designed to hold a load for extended periods.

4.2 Lowering the Load

- Ensure the area around the load is clear of personnel and obstructions.

- If jack stands are in use, slightly raise the load with the jack to remove the stands.

- Slowly turn the release valve counter-clockwise. The load will begin to descend. Control the descent speed by adjusting how much you open the valve.

- Once the load is fully lowered, remove the jack.

5. Maintenance

Regular maintenance ensures the longevity and safe operation of your Yato YT-1707 Bottle Jack.

5.1 Hydraulic Oil Level Check and Refill

- With the jack fully lowered, remove the oil filler plug.

- The oil level should be just below the filler hole.

- If low, refill with a high-quality hydraulic jack oil. Do not use brake fluid or motor oil.

- Replace the oil filler plug securely.

5.2 Cleaning and Lubrication

- Keep the jack clean and free of dirt, grease, and corrosive materials.

- Periodically lubricate moving parts with light machine oil.

5.3 Storage

Store the jack in a dry, clean environment with the ram fully retracted to protect the hydraulic seals.

6. Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Jack will not lift load. | Release valve open; Low hydraulic oil; Air in system; Overload. | Close release valve; Check/refill oil; Bleed system; Reduce load. |

| Jack lifts slowly or erratically. | Low hydraulic oil; Air in system; Worn seals. | Check/refill oil; Bleed system; Contact service for seal replacement. |

| Jack leaks oil. | Loose fittings; Damaged seals. | Tighten fittings; Contact service for seal replacement. |

| Jack will not lower. | Release valve stuck; Ram bent. | Gently try to open valve; Do not use if ram is bent, contact service. |

For issues not listed or if solutions do not resolve the problem, contact qualified service personnel.

7. Specifications

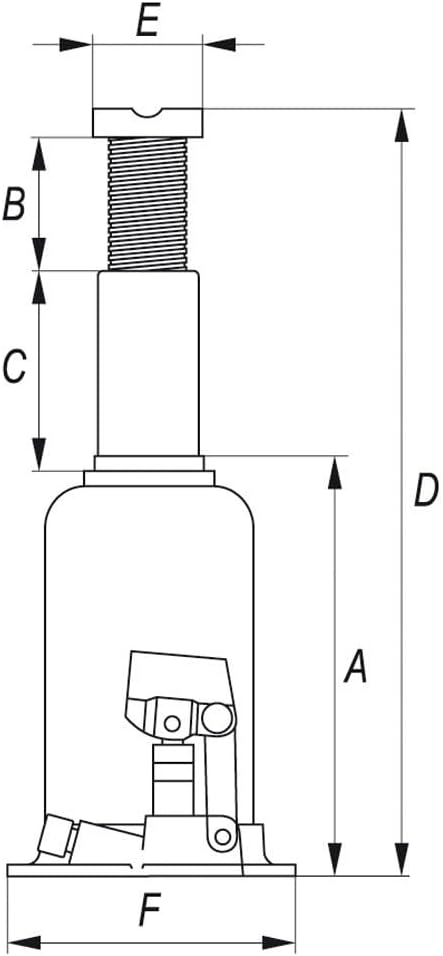

Figure 2: Dimensional diagram of the Yato YT-1707 Bottle Jack. This diagram illustrates various measurements labeled A through F, representing the jack's height, ram extension, and base dimensions.

| Feature | Value |

|---|---|

| Model | YT-1707 |

| Lifting Capacity | 20 tonnes |

| Minimum Height (A) | 242 mm |

| Maximum Height (D) | 520 mm |

| Lifting Range (Stroke) | 278 mm (520 mm - 242 mm) |

| Adjustable Screw Extension (B) | 6 cm |

| Weight | 11 kg (24.25 lbs) |

| Material | Alloy Steel |

| Color | Black |

Note: Dimensions A, B, C, D, E, F refer to the diagram above. Specific values for C, E, F are not provided in the source data.

8. Warranty and Support

Warranty information for the Yato YT-1707 Bottle Jack is not explicitly provided in the product details. Please refer to your purchase documentation or contact the seller, parts24h, for specific warranty terms and conditions.

For technical support or service inquiries, please contact your authorized Yato dealer or the retailer from whom you purchased the product.

Seller: parts24h