1. Introduction

This service manual provides detailed instructions and procedures for the maintenance, repair, and overhaul of Case 584D, 585D, and 586D forklift models. It is an essential resource for technicians and mechanics to ensure proper operation and longevity of the equipment. The manual covers various systems and components, offering step-by-step guidance, diagrams, and specifications.

The information contained herein is intended for qualified personnel familiar with the operation and servicing of heavy machinery. Always prioritize safety and follow all local regulations and manufacturer guidelines when performing any service procedures.

2. General Information

This section outlines fundamental information crucial for all service operations. It includes:

- Safety Rules: Important precautions and guidelines to prevent injury and equipment damage.

- Service Manual Introduction: Overview of the manual's structure and usage.

- Location of Serial Numbers and Product Identification Number (PIN): Guidance on finding critical identification markers on the forklift.

- Torque Specifications: Essential torque values for fasteners across various components.

Image: A page from the service manual showing the Table of Contents, detailing sections like General, Engines, Fuel System, and Electrical.

3. Engine System

Detailed procedures for the engine system are provided, covering:

- Engine Stall Tests: Diagnostics for engine performance under load.

- Engine Removal and Installation: Step-by-step guide for safely removing and reinstalling the engine.

- Engine Diagnosis: Methods for identifying engine malfunctions.

- Engine Tune-Up: Procedures for optimizing engine performance.

- Cylinder Head, Valve Train, Camshaft: Service instructions for these critical components.

- Cylinder Block, Sleeves, Pistons, and Rods: Repair and replacement guidelines.

- Crankshaft, Main Bearings, Flywheel, and Oil Seals: Maintenance and repair.

- Oil Pump, Cooling System, Engine Lubrication: Service procedures for these essential systems.

4. Fuel System

This section details the components and service procedures for the forklift's fuel system:

- Fuel Filters: Inspection and replacement.

- Fuel Injection Pump: Service and calibration.

- Fuel Injectors: Testing and maintenance.

- Fuel Lines, Fuel Tank, Engine Controls: Inspection and repair of fuel delivery components.

5. Electrical System

Information regarding the electrical system includes:

- Electrical System Troubleshooting: Diagnostic steps for electrical faults.

- Wiring Diagrams: Comprehensive schematics for electrical circuits.

- Batteries: Maintenance, testing, and replacement procedures.

6. Power Train

This section covers the power transmission components of the forklift.

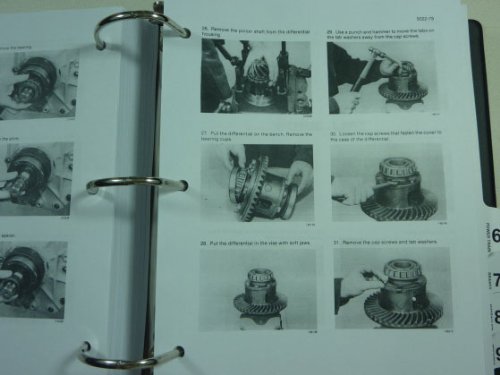

6.1 Differential Service

Detailed steps for servicing the differential unit, including removal, disassembly, inspection, and reassembly.

Image: A page illustrating step-by-step instructions with photographs for the removal and installation of the differential assembly.

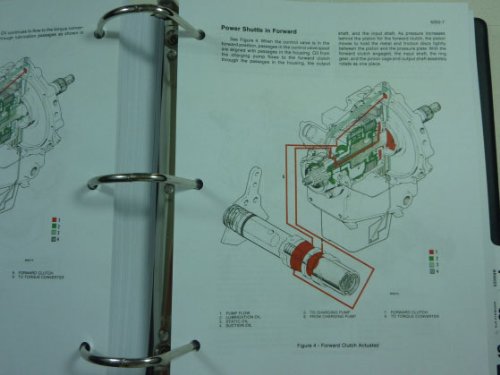

6.2 Power Shuttle Operation

Explanation of the power shuttle system, including its components and operational flow for forward and reverse gears.

Image: A detailed diagram illustrating the hydraulic flow and components of the power shuttle in forward operation.

7. Hydraulic System

This section provides comprehensive diagrams and explanations for the hydraulic system, crucial for forklift lifting and tilting functions.

Image: A complex diagram showing the hydraulic flow paths and valve configurations for various functions, including tilt and lift operations.

8. Specifications

Key specifications for the Case 584D, 585D, and 586D forklifts are provided to assist in service and parts identification.

- Manual Publication Date: January 1, 1985

- Publisher: TechMedia

- Language: English

- Print Length: 1232 pages

- General Specifications: Dimensions, weight, and capacities.

- Engine Specifications: Engine type, displacement, horsepower, and torque.

- Fluid Capacities: Oil, coolant, and hydraulic fluid volumes.

9. Maintenance and Lubrication

This section details routine maintenance schedules and lubrication points to ensure optimal performance and extend the lifespan of the forklift. It includes:

- Scheduled Maintenance Intervals: Recommended service checks at specific operating hours.

- Lubrication Points: Identification of all grease points and fluid check locations.

- Fluid Type and Capacity: Specifications for engine oil, hydraulic fluid, transmission fluid, and coolant.

- Filter Replacement: Guidelines for replacing oil, fuel, air, and hydraulic filters.

10. Troubleshooting

This section provides diagnostic charts and procedures to identify and resolve common operational issues. It specifically covers:

- Electrical System Troubleshooting: Step-by-step guides for diagnosing electrical faults, including starting issues, charging problems, and lighting malfunctions.

- Engine Performance Issues: Guidance for diagnosing problems such as misfires, overheating, and power loss.

- Hydraulic System Malfunctions: Troubleshooting for issues like slow lift, no lift, or erratic operation.

11. Support Information

For further assistance or inquiries regarding this service manual or the Case 584D, 585D, 586D forklifts, please refer to the original manufacturer's support channels or authorized Case service centers. This manual is a historical document published by TechMedia in 1985, and direct product support may vary for older equipment.

Always ensure that any replacement parts used are genuine Case parts or approved equivalents to maintain the integrity and safety of the equipment.