1. Introduction

This service manual provides detailed information for the maintenance, repair, and overhaul of Ford 2600, 3600, 4100, 4600, 5600, 6600, 6700, 7600, and 7700 series tractors. It is intended for qualified service technicians and individuals with a thorough understanding of mechanical systems. The manual contains step-by-step procedures, illustrations, and specifications necessary to perform various service operations.

Models Covered:

- Ford 2600 Tractor

- Ford 3600 Tractor

- Ford 4100 Tractor

- Ford 4600 Tractor

- Ford 5600 Tractor

- Ford 6600 Tractor

- Ford 6700 Tractor

- Ford 7600 Tractor

- Ford 7700 Tractor

Image 1.1: Front cover of the Ford Tractor Service Manual, displaying the models covered.

2. Safety Information

Always prioritize safety when performing any service or maintenance on your tractor. Failure to follow safety precautions can result in serious injury or death. This section outlines general safety guidelines.

- Read the Manual: Familiarize yourself with all instructions and warnings before beginning any work.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and sturdy footwear.

- Engine Off: Ensure the engine is turned off, the parking brake is engaged, and the key is removed before working on the tractor, unless specifically instructed otherwise for a diagnostic procedure.

- Support the Tractor: Use appropriate stands or blocks to support the tractor securely when working underneath it. Never rely solely on a jack.

- Fluid Handling: Be cautious when handling hot fluids (oil, coolant) and hydraulic pressure. Dispose of fluids responsibly.

- Battery Safety: Disconnect the battery before working on electrical components. Be aware of corrosive battery acid and explosive gases.

- Clean Work Area: Keep your work area clean and free of clutter to prevent accidents.

3. General Information and How to Use This Manual

This manual is organized into chapters, each covering a specific system or component of the tractor. Each chapter begins with an overview and includes detailed procedures, specifications, and diagnostic information. Illustrations and diagrams are provided to aid in understanding the instructions.

Key Features:

- Numbered Sections: Procedures are broken down into numbered steps for clarity.

- Figures and Tables: Visual aids and data tables are used extensively.

- Notes and Warnings: Important information, cautions, and warnings are highlighted.

- Specifications: Technical data, torque values, and fluid capacities are provided in relevant sections and a dedicated specifications chapter.

Image 3.1: The manual features tabbed sections for easy navigation to specific topics like Electrical, Rear Axle & Brakes, and Hydraulic Systems.

4. Maintenance Procedures

Regular maintenance is crucial for the longevity and optimal performance of your Ford tractor. This section outlines routine service tasks.

4.1 Engine Maintenance

Perform regular checks of engine oil levels, coolant levels, and air filter condition. Refer to the specifications section for recommended service intervals and fluid types.

4.2 Fluid Checks and Changes

Engine oil, transmission fluid, hydraulic fluid, and coolant should be checked and changed according to the manufacturer's schedule. Proper fluid levels and quality prevent premature wear.

4.3 Filter Replacement

Fuel filters, oil filters, air filters, and hydraulic filters must be replaced at specified intervals to ensure clean operation and prevent contamination of critical systems.

5. Engine Systems

This chapter details the various engine systems, including fuel, ignition, cooling, and lubrication. It provides procedures for diagnosis, repair, and adjustment.

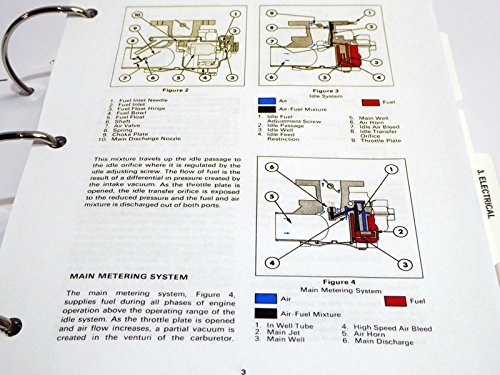

5.1 Fuel System

Procedures for servicing carburetors, fuel injection pumps, fuel lines, and filters. Includes adjustments and troubleshooting for fuel delivery issues.

Image 5.1: Detailed diagrams illustrating the idle system and main metering system of a carburetor, with numbered components and color-coded fuel/air mixture paths.

5.2 Timing Gear Alignment

Correct timing gear alignment is essential for proper engine operation. This section provides instructions for checking and adjusting timing gears.

Image 5.2: Figures demonstrating the alignment of timing gears and the distributor type fuel injection pump drive gear, crucial for engine synchronization.

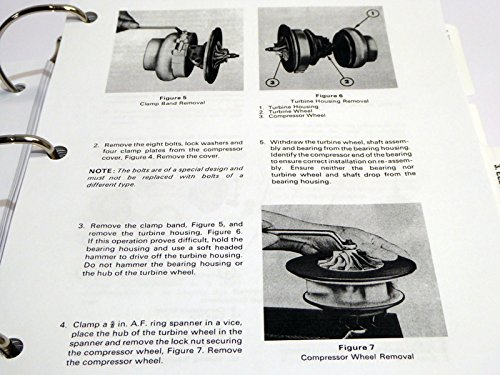

5.3 Turbocharger Service (If Applicable)

For models equipped with turbochargers, this section covers removal, inspection, and installation procedures for compressor and turbine components.

Image 5.3: Illustrations detailing the removal of the turbocharger clamp band and the compressor wheel, showing specific tools and steps.

6. Transmission and Driveline

This chapter covers the transmission, clutch, rear axle, and brakes, providing detailed repair and overhaul instructions.

6.1 Clutch System

Procedures for clutch removal, inspection, repair, and installation, including adjustments for proper operation.

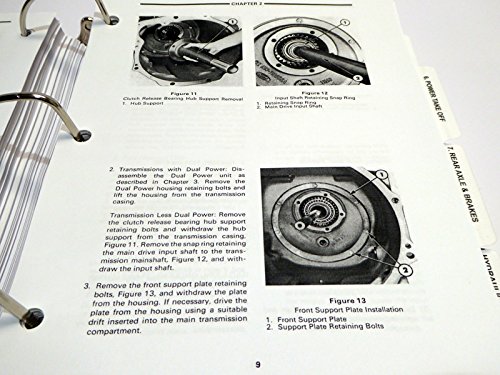

Image 6.1: Figures illustrating the removal of the clutch release bearing hub support and the input shaft retaining snap ring, key steps in clutch service.

6.2 Rear Axle and Brakes

Service procedures for the rear axle assembly, differential, and braking system components.

7. Hydraulic Systems

This section provides comprehensive information on the tractor's hydraulic system, including pumps, control valves, and cylinders.

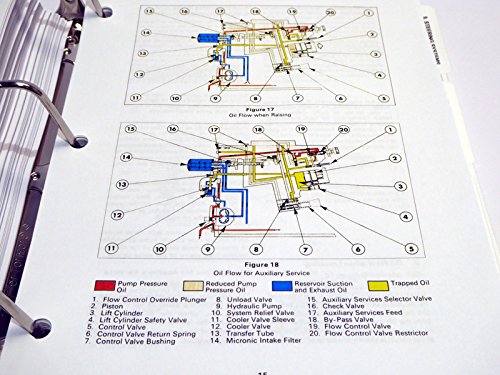

7.1 Hydraulic Oil Flow

Understanding the hydraulic oil flow is critical for diagnosing and repairing hydraulic issues. Diagrams illustrate oil paths during various operations.

Image 7.1: Diagrams depicting hydraulic oil flow during lifting operations and for auxiliary services, with components labeled and oil paths color-coded.

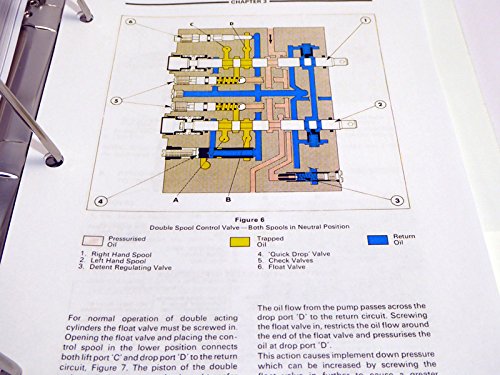

7.2 Control Valves

Detailed procedures for inspecting, disassembling, and reassembling hydraulic control valves, including double spool control valves.

Image 7.2: A diagram illustrating the internal workings of a double spool control valve in its neutral position, showing oil flow and component arrangement.

8. Electrical System

This chapter covers the tractor's electrical components, including wiring, charging system, starting system, and lighting.

8.1 Wiring Diagrams

Comprehensive wiring diagrams are provided to assist in diagnosing electrical faults and tracing circuits.

Image 8.1: A large, foldout electrical wiring diagram, providing a comprehensive overview of the tractor's electrical circuits and components.

8.2 Component Testing

Instructions for testing various electrical components such as alternators, starters, and switches.

9. Troubleshooting

This section provides a guide to common problems encountered with Ford tractors and systematic steps for diagnosing and resolving them. It includes charts for various symptoms and their potential causes.

- Engine Starting Issues: Diagnosis for no-start, hard-start, or poor-running conditions.

- Hydraulic System Malfunctions: Troubleshooting for slow, weak, or inoperative hydraulic functions.

- Transmission Problems: Addressing issues like gear engagement, slipping, or unusual noises.

- Electrical Faults: Guidance for identifying and repairing issues with lights, gauges, and charging systems.

10. Specifications

This chapter contains detailed technical specifications for all covered Ford tractor models. It includes critical data necessary for proper assembly, adjustment, and repair.

- Engine Specifications: Bore, stroke, displacement, compression ratio, valve clearances.

- Torque Specifications: Fastener torque values for various components (e.g., cylinder head, connecting rods, wheel nuts).

- Fluid Capacities: Engine oil, transmission fluid, hydraulic fluid, coolant capacities, and recommended types.

- Electrical Specifications: Battery voltage, alternator output, fuse ratings.

- Dimensions and Weights: General dimensions and operating weights for different models.

11. Support and Disclaimer

This service manual is a reproduction of the original manufacturer's service information, published by TechMedia. While every effort has been made to ensure accuracy, the publisher does not guarantee the completeness or correctness of the information contained herein. Users are advised to exercise caution and apply appropriate safety measures when performing any procedures.

This manual is provided for informational purposes only and does not imply any warranty or ongoing support from the publisher or original manufacturer. For specific parts or technical assistance beyond the scope of this manual, consult an authorized Ford service center or a qualified professional.