1. Introduction

Thank you for choosing the Amerec AI Series 9006-184 18KW Commercial Steam Boiler. This manual provides essential information for the safe and efficient installation, operation, and maintenance of your steam generator. Please read this manual thoroughly before installation and retain it for future reference. Proper installation and maintenance are crucial for optimal performance and longevity of the unit.

2. Safety Information

WARNING: Failure to follow these safety instructions could result in electric shock, fire, serious injury, or death.

- Installation and servicing must be performed by qualified personnel only, in accordance with all local and national electrical and plumbing codes.

- Ensure the main power supply is disconnected before performing any installation, maintenance, or troubleshooting.

- This unit operates at high temperatures and pressures. Exercise extreme caution.

- Do not operate the steam boiler if it is damaged or malfunctioning.

- Keep children and unauthorized persons away from the unit during operation.

- Ensure proper ventilation in the installation area.

- The unit must be properly grounded to prevent electrical shock.

3. Product Overview

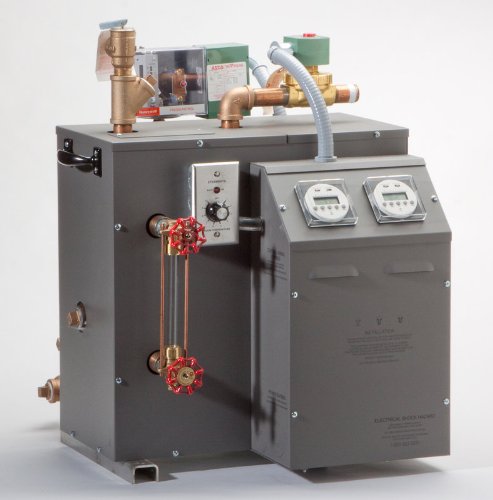

The Amerec AI Series 9006-184 is a high-performance 18KW commercial steam boiler designed for steam rooms ranging from 550 to 900 adjusted cubic feet (ACF). It features robust construction from corrosion-resistant steel and an ASME-certified pressure vessel for instant steam generation. Key components include durable electronic controls, a 3-level water sensing system with low water cutoff, and an electronic high-limit pressure control system.

Figure 3.1: Amerec AI Series 9006-184 18KW Commercial Steam Boiler. This image shows the exterior of the steam boiler unit, highlighting its compact design and robust construction.

The unit is equipped with safety features such as a room high-limit temperature safety system, an ASME safety valve, and an alarm circuit panic button connection. It includes two 3/4 Inch NPT steam heads and is designed for hardwired installation.

4. Setup & Installation

4.1 Pre-Installation Checklist

- Verify power supply: 240V, 3 Phase, 88 Amps.

- Ensure adequate space for the unit (Length: 17 1/2 Inch, Width: 20 3/4 Inch, Height: 23 1/4 Inch) and access for servicing.

- Confirm water supply and drain connections are available.

- Review local electrical and plumbing codes.

4.2 Mounting the Unit

The boiler is designed for floor installation. Select a level, stable surface capable of supporting the unit's weight (approximately 140 lbs). Ensure sufficient clearance around the unit for ventilation and maintenance access. Refer to the installation diagram (not pictured) for recommended clearances and mounting points.

4.3 Plumbing Connections

- Connect the water supply line to the designated inlet on the boiler. An inline shut-off valve and backflow preventer are recommended.

- Connect the 3/4 Inch drain port to an approved drainage system. Ensure proper slope for gravity drainage.

- Install the two 3/4 Inch NPT steam heads in the steam room according to the steam room design specifications. Connect the steam lines from the boiler to these heads.

4.4 Electrical Connections

All electrical work must be performed by a licensed electrician.

- Ensure the main power supply is OFF at the circuit breaker.

- Connect the 240V, 3 Phase power supply to the boiler's electrical terminal block (Electrical Location: Side).

- Properly ground the unit as per local electrical codes.

- Connect the optional D24/7 digital time clock and ADI-D Auto drain system if applicable.

- Connect the alarm circuit panic button if required.

5. Operating Instructions

5.1 Initial Startup

- After installation, ensure all plumbing and electrical connections are secure and leak-free.

- Open the water supply valve to the boiler.

- Restore power to the unit at the circuit breaker.

- The boiler will begin to fill with water. The 3-level water sensing system will monitor the water level.

- Once the appropriate water level is reached, the heating elements will activate, and steam production will begin.

5.2 Normal Operation

The Amerec AI Series boiler is designed for automatic operation. Once powered on and filled, it will maintain steam production as needed. The electronic high-limit pressure control systems regulate the steam output.

- Steam Production: Steam will be delivered to the steam room via the steam heads.

- Temperature Control: The room high-limit temperature safety system monitors the steam room temperature.

- Water Level: The sight glass allows visual inspection of the water level. The low water cut-off system will automatically shut down the unit if water levels are critically low, requiring a manual reset.

5.3 Shutting Down the Unit

To shut down the unit, turn off the power at the main circuit breaker. If an optional D24/7 digital time clock is installed, it can be used to schedule on/off times.

6. Maintenance

WARNING: Disconnect all power to the unit before performing any maintenance.

6.1 Regular Cleaning

- Drain Port: Periodically open the 3/4 Inch drain port to flush out sediment and mineral buildup. The frequency depends on water quality and usage.

- Automatic Drain System (ADI-D): If equipped, ensure the automatic drain system is functioning correctly.

- Exterior: Clean the exterior of the unit with a damp cloth. Do not use abrasive cleaners.

6.2 Descaling

Mineral deposits can accumulate inside the boiler, affecting efficiency. Descaling should be performed by a qualified technician. The frequency of descaling depends on water hardness and usage.

6.3 Annual Inspection

An annual inspection by a qualified service technician is recommended to check all components, including heating elements, sensors, safety valves, and electrical connections, to ensure continued safe and efficient operation.

7. Troubleshooting

Before contacting customer support, review the following common issues and solutions.

| Problem | Possible Cause | Solution |

|---|---|---|

| No steam production | No power to unit | Check circuit breaker. Ensure unit is properly wired. |

| No steam production | Low water level / Low water cut-off activated | Ensure water supply is open. Manually reset low water cut-off if necessary after verifying water level. |

| No steam production | High-limit pressure control activated | Allow unit to cool. Check for obstructions in steam lines or steam heads. |

| Unit leaks water | Loose plumbing connections | Tighten all plumbing connections. Inspect for damaged seals or pipes. |

| Steam room not hot enough | Improper room size for boiler capacity | Verify steam room ACF is within the 550-900 range. Consult a professional if room is too large. |

For issues not listed or if troubleshooting steps do not resolve the problem, contact Amerec customer support or a qualified service technician.

8. Specifications

| Feature | Detail |

|---|---|

| Model Number | 9006-184 |

| Power Output | 18 KW |

| Voltage | 240V |

| Phase | 3 Phase |

| Amperage | 88 Amps |

| Room Volume (ACF) | 550 - 900 C.F. |

| Material | Corrosion-resistant Steel |

| Installation Type | Floor |

| Weight | 140 lbs (Item Weight) |

| Dimensions (L x W x H) | 17 1/2 Inch x 20 3/4 Inch x 23 1/4 Inch |

| Drain Port | 3/4 Inch |

| Steam Heads Included | Two 3/4 Inch NPT |

| Certifications | ASME Certified Pressure Vessel, UL Listed |

9. Warranty & Support

9.1 Limited Warranty

The Amerec AI Series 9006-184 Commercial Steam Boiler comes with a limited warranty. Please refer to the warranty card included with your product packaging for specific terms, conditions, and duration of coverage. The warranty typically covers defects in materials and workmanship under normal use and service.

9.2 Customer Support

For technical assistance, parts, or warranty claims, please contact Amerec customer support. Have your model number (9006-184) and date of purchase ready when contacting support.

Amerec Customer Service:

Please visit the official Amerec website for current contact information, including phone numbers and email addresses.