Introduction

This manual provides essential instructions for the safe and effective operation, maintenance, and handling of the Vestil HPC-20 Steel Horizontal Plate Clamp. Please read this manual thoroughly before using the product to ensure proper understanding and to prevent injury or damage.

Safety Information

WARNING: Failure to follow these safety instructions can result in serious injury or death.

- Always inspect the clamp for damage or wear before each use. Do not use if damaged.

- Ensure the clamp is rated for the load capacity. Do not exceed the 2,000 Lb. (907 kg) capacity.

- Do not use plate clamps to lift loads less than 20 percent of rated capacity.

- Lift only one plate at a time.

- The plate must be clean and free of oil, grease, or other slippery substances to ensure a secure grip.

- This clamp is not designed for use on stainless steel or aluminum plates.

- For use with materials with a surface hardness up to 30 RC (300 HB).

- Ensure the load is balanced and stable before lifting.

- Keep hands and body clear of the load during lifting and lowering operations.

- Always use appropriate personal protective equipment (PPE).

- This product meets ASME B30.20 specifications. Adhere to all applicable safety standards and regulations.

Product Components

The Vestil HPC-20 Horizontal Plate Clamp consists of the following main components:

- Lifting Eye: Top attachment point for lifting equipment.

- Body: The main frame of the clamp, typically blue.

- Cam/Jaw: The serrated, movable part that grips the plate.

- Fixed Jaw: The stationary part that supports the plate.

- Locking Mechanism: A button or lever to engage/disengage the clamp.

Image: The Vestil HPC-20 Horizontal Plate Clamp, showing its main components including the lifting eye, blue body, and serrated jaw.

Image: Close-up view of the Vestil HPC-20 clamp, highlighting the product label with capacity and model information.

Setup

- Unpacking: Carefully remove the clamp from its packaging.

- Initial Inspection: Before first use, thoroughly inspect the clamp for any signs of shipping damage, cracks, deformities, or missing parts. Ensure all moving parts operate smoothly.

- Familiarization: Understand the locking mechanism and how the jaws open and close.

Operating Instructions

Follow these steps for safe and effective horizontal plate lifting:

- Prepare the Plate: Ensure the plate to be lifted is clean, dry, and free of oil, grease, paint, or other coatings that could reduce friction. Verify the plate material is suitable for this clamp (not stainless steel or aluminum).

- Open the Clamp: Press the locking button/lever to release the cam and open the clamp jaws.

Image: Hands demonstrating how to open the clamp jaws by pressing the release button.

- Position the Clamp: Place the clamp onto the edge of the plate, ensuring the plate is fully seated between the fixed jaw and the cam. The clamp should be positioned securely and centrally on the plate's edge for balanced lifting.

- Engage the Clamp: Release the locking button/lever, allowing the cam to firmly grip the plate. The serrated surface of the cam should make full contact with the plate.

Image: Hands demonstrating how to close the clamp jaws, allowing the cam to engage the plate.

Image: The Vestil HPC-20 clamp securely engaged on the edge of a diamond plate, ready for lifting.

- Test Lift: Before full lift, apply slight tension to the lifting equipment to ensure the clamp has a secure grip and the plate is stable. If any slippage occurs, lower the load immediately and re-position the clamp.

- Lifting: Lift the plate slowly and smoothly, avoiding sudden jerks or movements. Maintain control of the load at all times.

- Lowering and Releasing: Lower the plate gently to its destination. Once the plate is fully supported and stable, press the locking button/lever to open the cam and release the clamp.

Maintenance

- Regular Inspection: Periodically inspect the clamp for wear, especially on the serrated gripping surfaces of the jaws. Check for any deformation, cracks, or corrosion on the body and lifting eye.

- Cleaning: Keep the clamp clean, especially the gripping surfaces, to ensure maximum friction and secure holding. Remove any debris, rust, or foreign material.

- Lubrication: Lightly lubricate pivot points and moving parts with a suitable lubricant to ensure smooth operation. Avoid lubricating gripping surfaces.

- Storage: Store the clamp in a dry, clean environment when not in use to prevent rust and damage.

- Professional Service: If significant wear or damage is observed, or if the clamp does not operate correctly, remove it from service immediately and contact a qualified technician or the manufacturer for repair or replacement.

Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Clamp slips on plate |

|

|

| Clamp mechanism stiff/stuck |

|

|

Specifications

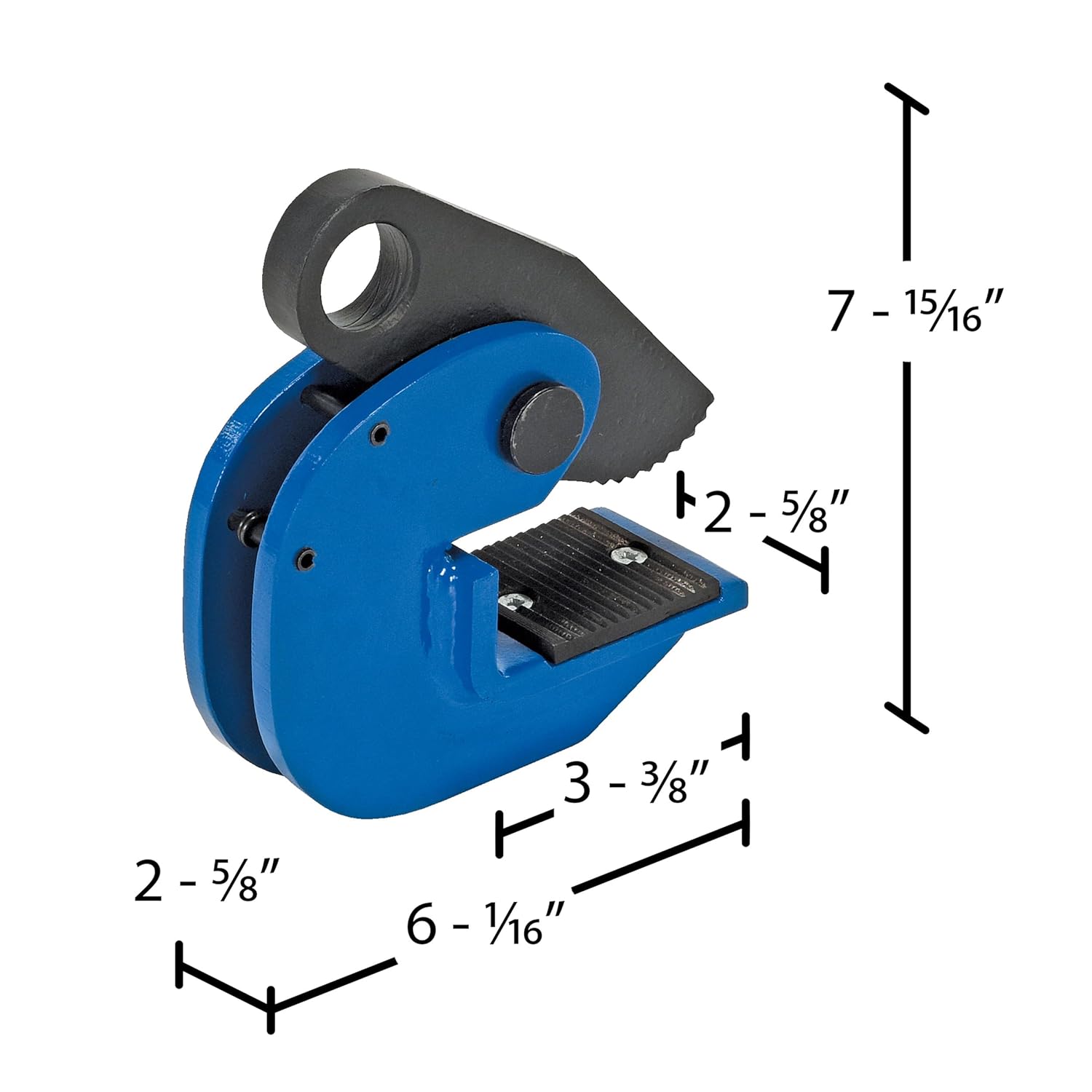

Image: Dimensional drawing of the Vestil HPC-20 Horizontal Plate Clamp with key measurements.

| Feature | Detail |

|---|---|

| Model Number | HPC-20 |

| Brand | Vestil |

| Capacity (Uniform Working Load Limit) | 2,000 Lb. (907 kg) |

| Minimum Uniform Plate Weight | 400 Lb. (181 kg) |

| Material | Alloy Steel |

| Product Dimensions (L x W x H) | 6.06 x 2.63 x 7.94 inches |

| Item Weight | 6 Pounds (2.72 kg) |

| Color | Blue |

| Compliance | Meets ASME B30.20 specifications |

| Manufacturer | Vestil Manufacturing Co. |

Warranty and Support

For warranty information, technical support, or service inquiries regarding your Vestil HPC-20 Steel Horizontal Plate Clamp, please contact Vestil Manufacturing Co. directly. Refer to the contact information provided with your purchase documentation or visit the official Vestil website.