1. Introduction

The ENGINEER PZ-58 Screw Removal Pliers are a specialized hand tool designed for the efficient extraction of damaged, rusted, or specialized screws that cannot be removed with conventional screwdrivers or pliers. Featuring unique non-slip jaws and a robust construction, these pliers provide a secure grip on screw heads, allowing for effective removal without further damage to the fastener or surrounding material. This manual provides detailed instructions for the proper use, maintenance, and care of your PZ-58 pliers to ensure optimal performance and longevity.

Figure 1.1: The ENGINEER PZ-58 Screw Removal Pliers, showcasing their ergonomic green handles and precision-machined jaws.

2. Key Features

The PZ-58 pliers incorporate several design elements that enhance their functionality and effectiveness:

- Unique Non-Slip Jaws: The jaws are engineered with a vertical and horizontal serration pattern, providing a superior grip on screw heads, even those that are severely stripped or rusted. This design minimizes slippage during rotation.

- Intermeshed Jaw Teeth: An innovative design allows the jaw teeth to intermesh precisely, enabling a firm grip on very thin materials or small screw heads.

- Integrated Side Cutting Jaws: Equipped with sharp side cutters, the pliers can also be used for cutting wires or small metal components, adding to their versatility.

- Ergonomic Handles: The handles are coated with an elastomer grip, providing comfort and reducing hand fatigue during prolonged use.

- Spring-Loaded Mechanism: A spring keeps the pliers open in the resting position, facilitating one-handed operation and quick repositioning.

Figure 2.1: A detailed view of the PZ-58's uniquely serrated and intermeshed jaws, designed for maximum grip.

Figure 2.2: Close-up demonstrating the precision of the intermeshed jaw teeth, allowing for a secure hold on small or thin objects.

3. Setup and Preparation

The ENGINEER PZ-58 pliers require minimal setup. Before use, ensure the following:

- Inspect the Tool: Visually inspect the pliers for any signs of damage, wear, or debris that might affect their performance. Ensure the jaws open and close smoothly.

- Clear Workspace: Ensure your work area is well-lit and free of obstructions. Identify the screw to be removed and assess its condition.

- Safety First: Always wear appropriate personal protective equipment, such as safety glasses, when working with tools.

4. Operating Instructions

Follow these steps for effective screw removal:

- Position the Jaws: Open the pliers and position the unique serrated jaws around the head of the damaged or rusted screw. Ensure the jaws are gripping the screw head as firmly and completely as possible. The pliers are designed to grip various screw head types, including truss and pan heads.

- Apply Firm Pressure: Squeeze the handles firmly to ensure a secure grip on the screw head. The non-slip design of the jaws is crucial for preventing cam-out.

- Rotate and Extract: While maintaining firm pressure, slowly rotate the pliers counter-clockwise to loosen and extract the screw. For very stubborn screws, apply steady, increasing pressure and a controlled rotation.

- Repeat if Necessary: If the screw does not turn on the first attempt, reposition the pliers and try again, adjusting your grip for better leverage.

Figure 4.1: Demonstrating the PZ-58 pliers gripping a screw head for removal.

Figure 4.2: The pliers effectively gripping a truss head screw.

Figure 4.3: The pliers effectively gripping a pan head screw.

Figure 4.4: Examples of various damaged and specialized screw heads that the PZ-58 pliers are designed to extract.

Note on Video Content: No official product videos from the seller were available for embedding in this manual.

5. Maintenance

Proper maintenance ensures the longevity and performance of your PZ-58 pliers:

- Cleaning: After each use, wipe the pliers clean with a dry cloth to remove any dirt, grease, or debris. For stubborn grime, a slightly damp cloth can be used, followed by thorough drying.

- Lubrication: Periodically apply a small amount of light machine oil to the pivot point to ensure smooth operation and prevent rust.

- Storage: Store the pliers in a dry environment to prevent corrosion. Consider using a protective cap or rubber band to keep the jaws closed during storage, especially if transporting them in a toolbox.

- Inspection: Regularly inspect the jaw serrations for wear or damage. While made from high-carbon steel, excessive force on extremely hardened screws can cause wear over time.

6. Troubleshooting

If you encounter issues while using your PZ-58 pliers, consider the following:

| Problem | Possible Cause | Solution |

|---|---|---|

| Pliers slip on screw head. | Insufficient grip pressure; screw head too severely damaged; screw material too hard. | Ensure a very firm grip. Reposition the pliers to find a better purchase point. The pliers are not designed for extremely hardened screws (e.g., Grade 8 bolts). |

| Screw does not turn. | Screw is seized due to rust or threadlocker; insufficient torque applied. | Apply penetrating oil to rusted screws and allow time to work. Ensure maximum grip and apply steady, firm rotational force. For extremely seized screws, additional methods may be required. |

| Jaws feel stiff or sticky. | Accumulation of dirt/debris; lack of lubrication. | Clean the pliers thoroughly, especially around the pivot point. Apply a small amount of light machine oil to the pivot. |

7. Specifications

Detailed specifications for the ENGINEER PZ-58 Screw Removal Pliers:

| Attribute | Detail |

|---|---|

| Brand | ENGINEER |

| Model Number | PZ-58 |

| Material (Body) | High carbon steel |

| Material (Grip) | Elastomer |

| Product Dimensions | 6.3"L x 2.13"W (160mm x 54mm) |

| Color | Green |

| Item Weight | 149 Grams (5.3 ounces) |

| Specific Uses | Professional, Amateur (Screw removal, wire cutting) |

| Grip Type | Ergonomic |

| Cutting Width | 0.05 Inches |

| Applicable Screw Head Diameter | Φ3~9.5mm |

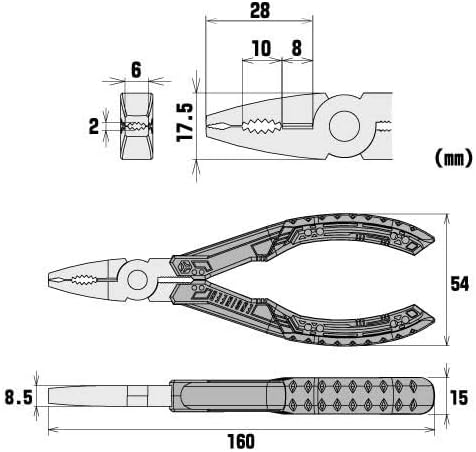

Figure 7.1: Technical drawing illustrating the dimensions of the PZ-58 pliers in millimeters.

8. Warranty and Support

The ENGINEER PZ-58 Screw Removal Pliers are manufactured to high-quality standards. For information regarding warranty coverage, please refer to the warranty documentation provided with your purchase or visit the official ENGINEER website. For technical support or inquiries, please contact the manufacturer's customer service department.

For further assistance, you may also refer to the ENGINEER Store on Amazon.