1. Introduction and Product Overview

The Williams 1230MSC Super Torque Combination Wrench is a high-quality, durable hand tool designed for professional and industrial use. Manufactured from special alloy steel, this 30 Millimeter wrench features both high polish chrome and satin chrome finishes, offering superior performance and longevity. Its innovative design allows for increased torque application without damaging fasteners, making it an essential tool for various applications.

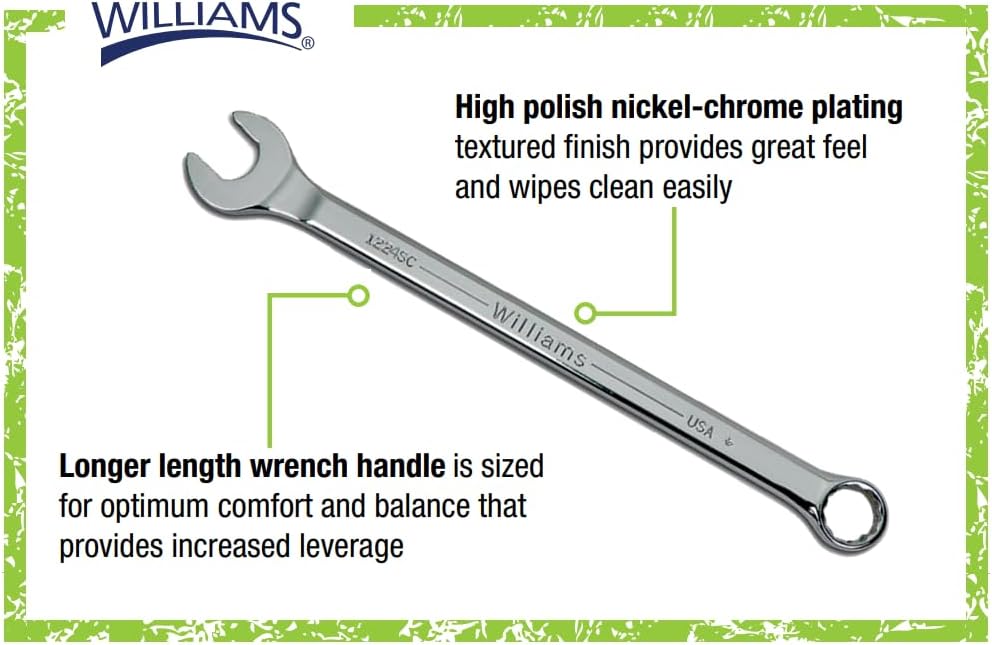

Figure 1: Williams 1230MSC Super Torque Combination Wrench, 30 Millimeter.

Key features include:

- SUPERTORQUE Box Opening Design: Allows application of higher torque without rounding or deforming hex fastener points by placing wrenching forces on the flat surfaces behind the points, not the corners.

- Enhanced Maneuverability: Features a 7.5-degree offset broach, enabling 15-degree access when engaging a fastener, particularly useful in confined spaces.

- Superior Material Quality: Precision forged and heat-treated special alloy steel ensures optimum strength and durability.

- High Performance Standards: Meets or exceeds aerospace specification AS 954 for 12-point fasteners (as defined by AS 870), ensuring accurate torque/tension relationship for precision applications.

- Ergonomic Design: Longer handle length is sized for optimum comfort and balance, providing increased leverage. Rounded edges on the wrench body enhance user comfort.

- High Polish Nickel-Chrome Plating: Provides a great feel, is easy to clean, and offers excellent corrosion resistance.

2. Features and Design

The Williams Super Torque Combination Wrench incorporates several design elements to maximize efficiency and user experience.

Figure 2: SUPERTORQUE™ Box End Design, preventing fastener rounding.

Figure 3: Longer length wrench handle for increased leverage and high polish nickel-chrome plating.

Figure 4: Detailed view of SUPERTORQUE™ box opening and SUPERCOMBO® open end grooves.

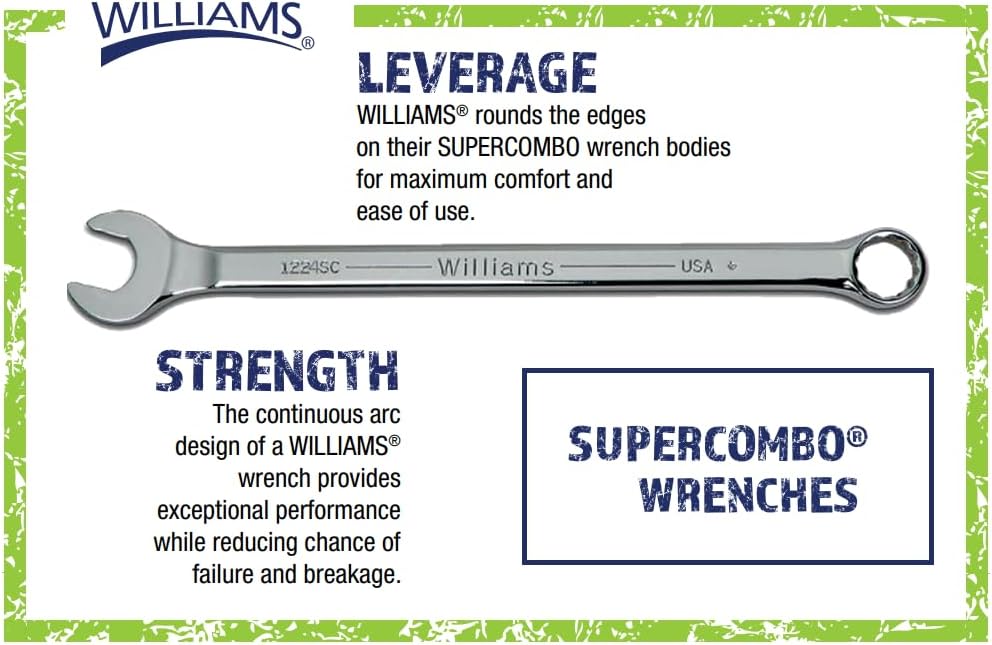

Figure 5: Design features for enhanced leverage and structural strength.

3. Setup and Initial Inspection

Upon receiving your Williams Super Torque Combination Wrench, perform a brief inspection to ensure it is in optimal condition for use.

- Unpacking: Carefully remove the wrench from its packaging.

- Visual Inspection: Check the wrench for any signs of damage, such as cracks, bends, or excessive wear on the jaws or box end. The chrome finish should be intact and free from significant blemishes.

- Size Verification: Confirm the size marking (30 Millimeter for this model) matches your requirements.

- Cleanliness: Ensure the wrench is clean and free of any debris or manufacturing residues before first use.

No specific setup or assembly is required for this combination wrench. It is ready for immediate use after inspection.

4. Operating Instructions

The Williams Super Torque Combination Wrench is designed for tightening and loosening hex (6-point) fasteners. Follow these guidelines for safe and effective operation:

- Select Correct Size: Always use the correct size wrench for the fastener. Using an incorrect size can damage both the fastener and the wrench, and may lead to injury.

- Proper Engagement:

- For the open end, ensure the wrench jaws fully engage the fastener head.

- For the box end, slide the box end completely over the fastener head. The SUPERTORQUE design will grip the flats of the fastener, not the corners.

- Apply Force Correctly:

- Pull on the wrench handle rather than pushing, to minimize the risk of injury if the wrench slips.

- Apply steady, even pressure. Avoid sudden jerking motions.

- Utilize the full length of the handle for maximum leverage, especially for stubborn fasteners.

- Working in Confined Spaces: The 7.5-degree offset broach of the box end allows for easier access and turning in tight areas. Flip the wrench to achieve a 15-degree access angle if needed.

- Safety Precautions:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, to protect against flying debris.

- Do not use extension pipes or "cheater bars" on the wrench handle, as this can overstress the tool and cause breakage or injury.

- Do not strike the wrench with a hammer or other tools unless the wrench is specifically designed for striking.

- Ensure a stable footing and balance before applying significant force.

Figure 6: Proper application of the wrench on pipe fittings.

Figure 7: Demonstrating effective grip and leverage.

Figure 8: Example of using a large wrench for high-torque applications.

5. Maintenance

Proper maintenance will extend the life of your Williams Super Torque Combination Wrench and ensure its continued performance.

- Cleaning: After each use, wipe the wrench clean with a dry cloth to remove dirt, grease, and grime. For stubborn residue, use a mild degreaser and then wipe dry.

- Rust Prevention: The chrome finish provides good corrosion resistance, but for long-term storage or in humid environments, apply a light coat of rust-preventative oil.

- Storage: Store the wrench in a dry, clean environment, preferably in a tool roll, drawer, or on a tool board to prevent damage from impacts or contact with other tools.

- Inspection: Periodically inspect the wrench for any signs of wear, such as rounded corners on the open end, cracks, or deformation. Discontinue use of any damaged tool.

6. Troubleshooting

While the Williams Super Torque Combination Wrench is designed for reliability, understanding potential issues can help maintain its effectiveness.

| Problem | Possible Cause | Solution |

|---|---|---|

| Wrench slips on fastener | Incorrect wrench size; Worn fastener head; Improper engagement; Excessive force at an angle. | Ensure correct size is used. Replace worn fasteners. Fully engage wrench. Apply force straight and steadily. |

| Fastener head rounding | Incorrect wrench size; Worn wrench jaws/box end; Applying force to corners instead of flats. | Use correct size. Inspect wrench for wear and replace if necessary. Ensure proper engagement on flats (especially with SUPERTORQUE box end). |

| Wrench feels uncomfortable or causes hand strain | Improper grip; Prolonged use without breaks; Applying force incorrectly. | Ensure a firm, comfortable grip. Take breaks during prolonged use. Pull, do not push, on the wrench. |

If the wrench shows signs of damage (e.g., bending, cracking, significant wear), it should be replaced immediately to prevent injury or further damage to fasteners.

7. Specifications

Detailed specifications for the Williams 1230MSC Super Torque Combination Wrench:

| Attribute | Value |

|---|---|

| Model Number | 1230MSC |

| Size | 30 Millimeters |

| Brand | Williams |

| Material | Alloy Steel |

| Color | Chrome |

| Finish Type | Polished |

| Head Style | Box End, Open End |

| Item Length | 16.28 Inches |

| Item Weight | 2.27 pounds |

| Measurement System | Metric |

| UPC | 662459901903 |

Figure 9: Comprehensive size chart for Williams SUPERCOMBO® Combination Wrenches.

Figure 10: Diagram illustrating key dimensions (A, B, C, D, E) of the wrench.

8. Warranty and Support

Williams tools are built to last and are backed by a commitment to quality. For specific warranty information and customer support, please refer to the official Williams website or contact their customer service directly.

Williams has been manufacturing high-quality industrial tools for over 140 years, focusing on strength, reliability, and user confidence.

For additional information or to explore other Williams products, visit the official Williams Store: Williams Industrial Store.