1. Introduction

This manual provides essential instructions for the safe and effective use of your KTC Grease Gun Model CG400. This cartridge-type grease gun is designed for easy grease filling and efficient lubrication, helping to save grease during application. Please read this manual thoroughly before operating the device and retain it for future reference.

2. Safety Information

Always observe the following safety precautions to prevent injury or damage to the product.

- Wear appropriate personal protective equipment (PPE), including safety glasses, to protect against grease splashes.

- Do not point the grease gun nozzle at yourself or others. High-pressure grease injection can cause serious injury.

- Ensure the grease gun is clean before and after use to prevent contamination of lubricants.

- Use only the recommended type of grease for your application. Refer to the equipment manufacturer's specifications.

- Keep out of reach of children. This tool is not a toy.

- Store the grease gun in a dry, clean place when not in use.

- Do not modify the grease gun. Unauthorized modifications can lead to malfunction and injury.

3. Product Overview

The KTC Grease Gun CG400 is a robust tool designed for efficient lubrication tasks. It features a cartridge-type design for easy and clean grease loading.

Figure 3.1: KTC Grease Gun CG400 Technical Diagram. This diagram provides a detailed view of the grease gun's components and key dimensions (L and D). It also includes a table outlining specifications such as capacity, discharge volume, maximum pressure, and included nozzle type (G-250N5).

Figure 3.2: KTC Grease Gun CG400. This image displays the primary view of the KTC Grease Gun CG400, highlighting its metallic construction and lever mechanism. A red grease cartridge is shown alongside the gun, indicating its cartridge-type design.

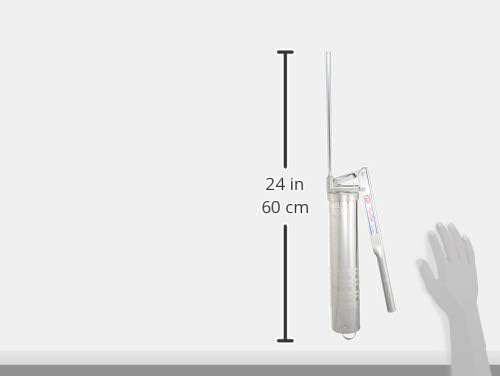

Figure 3.3: KTC Grease Gun CG400 Dimensions. This image illustrates the overall length of the grease gun, indicating approximately 24 inches (60 cm) from the tip of the nozzle to the end of the handle. This provides a clear understanding of the tool's physical size.

4. Setup

Follow these steps to prepare your KTC Grease Gun CG400 for use:

- Unscrew the barrel: Hold the grease gun firmly and unscrew the barrel from the head assembly.

- Insert grease cartridge: Remove the caps from both ends of a standard 400g grease cartridge. Carefully insert the cartridge into the barrel, ensuring it is seated correctly.

- Reattach the barrel: Screw the barrel back onto the head assembly until it is hand-tight.

- Prime the gun (if necessary): If the gun does not dispense grease immediately, release the plunger rod lock and push the plunger rod fully into the barrel to create pressure. Pump the handle several times until grease begins to flow from the nozzle.

- Attach nozzle: Ensure the appropriate nozzle (e.g., G-250N5) is securely attached to the grease gun. Other nozzles may be purchased separately depending on application needs.

5. Operation

Operating the KTC Grease Gun CG400 is straightforward:

- Connect to fitting: Press the grease gun nozzle firmly onto the grease fitting (zerk) of the component to be lubricated. Ensure a tight seal to prevent grease leakage.

- Pump the handle: Squeeze the lever handle repeatedly to dispense grease. Each full stroke of the handle discharges approximately 1 cubic centimeter (cc) of grease.

- Monitor grease flow: Observe the component being lubricated. Stop pumping when fresh grease appears, or when the manufacturer's recommended amount has been applied. Avoid over-greasing.

- Disconnect: To remove the nozzle from the fitting, twist it slightly while pulling.

Important: The grease gun operates at high pressure (up to 20 MPa). Always exercise caution during use.

6. Maintenance

Proper maintenance ensures the longevity and reliable performance of your grease gun.

- Cleaning: After each use, wipe down the exterior of the grease gun with a clean cloth to remove any excess grease or dirt. Keep the nozzle clean to prevent contamination.

- Storage: Store the grease gun in a clean, dry environment, away from direct sunlight and extreme temperatures. Ensure the plunger rod is fully retracted and locked to prevent accidental discharge.

- Nozzle Inspection: Periodically inspect the nozzle for wear or damage. Replace worn nozzles to ensure a proper seal with grease fittings.

- Cartridge Replacement: When a cartridge is empty, replace it following the setup instructions. Do not attempt to refill used cartridges unless they are specifically designed for refilling.

7. Troubleshooting

If you encounter issues with your KTC Grease Gun CG400, refer to the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| No grease dispenses | Air pocket in the gun; empty cartridge; clogged nozzle; plunger rod not engaged. | Prime the gun by pushing the plunger rod in; replace cartridge; clean or replace nozzle; ensure plunger rod is fully engaged. |

| Grease leaks from nozzle/fitting | Loose nozzle; worn nozzle tip; damaged grease fitting. | Tighten nozzle; replace nozzle; inspect and replace damaged grease fitting. |

| Difficulty pumping | Grease too thick for temperature; air lock. | Warm the grease cartridge slightly; prime the gun to remove air. |

8. Specifications

Key technical specifications for the KTC Grease Gun CG400:

| Feature | Value |

|---|---|

| Model Number | CG400 |

| Discharge Volume | 1 cc per stroke |

| Nozzle Length | 9.8 inches (250 mm) |

| Oil Tank Diameter | 2.2 inches (56 mm) |

| Capacity | 10.2 fl oz (290 cc) / 400g cartridge |

| Total Length | 14.2 inches (360 mm) |

| Item Weight | 2.9 pounds |

| Product Dimensions | 16.69 x 5.55 x 3.46 inches |

| Manufacturer | Kyoto Machine Tool (KTC) |

9. Warranty and Support

For warranty information, technical support, or to inquire about replacement parts, please contact your retailer or the manufacturer directly. Keep your purchase receipt as proof of purchase.

Manufacturer: Kyoto Machine Tool (KTC)