Product Overview

The CMT 240.008.04 Biscuit Joiner Blade is designed for efficient and precise biscuit joining operations. This 4-inch diameter blade features 8 teeth and is coated with CMT's trademark orange PTFE industrial coating, which helps reduce pitch and resin buildup and protects the blade from corrosion. It is engineered with high-grade German steel and micrograin carbide-tipped teeth for durability and long-lasting performance.

Key features include:

- Facilitates quick and easy biscuit joining.

- Constructed from high-grade German steel with 6 micrograin carbide-tipped teeth for extended use.

- Compatible with popular biscuit joiner models such as Lamello, DeWalt, Skil, Bosch, and Freud.

- Features 10° ATB (Alternate Top Bevel) Teeth and a 15° Cutting Angle for clean cuts.

Image: The CMT 240.008.04 Biscuit Joiner Blade, showcasing its orange PTFE coating, 4-inch diameter, 8 teeth, and recommended use for various biscuit joiner brands.

Setup and Installation

Before installing the blade, ensure your biscuit joiner is unplugged from the power source to prevent accidental startup. Always wear appropriate safety gear, including eye protection and gloves, during installation and operation.

- Power Disconnection: Disconnect the biscuit joiner from its power supply.

- Access Blade Compartment: Refer to your biscuit joiner's manual for specific instructions on how to open the blade compartment. This usually involves removing a cover or guard.

- Remove Old Blade (if applicable): If replacing an existing blade, carefully remove it. Note the orientation of the old blade for correct installation of the new one. Use a wrench or hex key if required to loosen the arbor nut.

- Install New Blade: Place the CMT 240.008.04 blade onto the arbor, ensuring it is seated correctly and the teeth are oriented for cutting. The blade has a 22mm bore.

- Secure Blade: Tighten the arbor nut securely. Do not overtighten.

- Reassemble: Replace any covers or guards that were removed. Ensure all components are properly secured before reconnecting power.

This blade is designed to fit a variety of popular biscuit joiner models, including Lamello, DeWalt, Skil, Bosch, and Freud. Verify compatibility with your specific tool model before installation.

Operating Instructions

The CMT 240.008.04 blade is engineered for precise and clean cuts in wood. Proper operation of your biscuit joiner with this blade will ensure optimal results for strong, invisible joints.

- Safety First: Always wear safety glasses, hearing protection, and appropriate work gloves. Ensure your workpiece is securely clamped.

- Adjust Depth and Angle: Set the cutting depth and angle on your biscuit joiner according to the size of the biscuits you are using and the joint type. The blade features a 15° cutting angle and 10° ATB teeth for efficient material removal.

- Marking: Accurately mark the locations for your biscuit slots on both pieces of wood to be joined.

- Cutting Slots: Align the biscuit joiner with your marks. With a firm grip, plunge the tool into the workpiece to cut the slot. Allow the blade to reach full speed before engaging the material. Apply steady, controlled pressure.

- Clean Cuts: The PTFE coating on the blade helps minimize friction and prevents pitch and resin buildup, contributing to cleaner cuts and smoother operation.

- Maximum RPM: Do not exceed the maximum recommended RPM for the blade, which is 14,000 RPM.

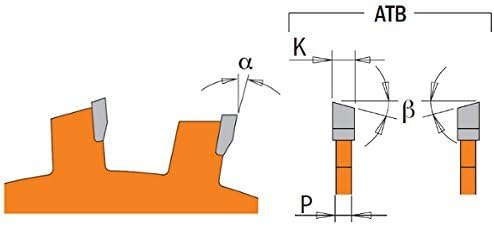

Image: A diagram illustrating the Alternate Top Bevel (ATB) tooth configuration of the blade, showing the angles (alpha and beta) and dimensions (K and P) that contribute to its cutting performance.

Image: An illustrative diagram demonstrating how a biscuit joint is formed, with the biscuit inserted into the slots cut by the joiner blade, connecting two pieces of wood.

Maintenance

Regular maintenance will extend the life and performance of your CMT biscuit joiner blade.

- Cleaning: After each use, disconnect the tool from power and carefully clean the blade. The orange PTFE coating helps resist pitch and resin buildup, making cleaning easier. Use a suitable blade cleaner and a soft brush or cloth to remove any accumulated debris. Avoid abrasive materials that could damage the coating or carbide tips.

- Inspection: Periodically inspect the carbide teeth for signs of wear, chipping, or damage. A dull or damaged blade can lead to poor cut quality and increased strain on your tool.

- Storage: Store the blade in a dry, clean environment, preferably in its original packaging or a protective case, to prevent corrosion and damage to the teeth.

- Sharpening: While the carbide tips are designed for long life, if the blade becomes dull, it should be professionally sharpened by a qualified service that specializes in carbide tooling. Do not attempt to sharpen it yourself unless you have the proper equipment and expertise.

Troubleshooting

If you encounter issues with your CMT biscuit joiner blade, consider the following common problems and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Rough or splintered cuts | Dull blade, incorrect feed rate, excessive pitch buildup. | Clean the blade. If still rough, consider professional sharpening or replacement. Adjust feed rate to be slower and more controlled. |

| Blade overheating | Dull blade, excessive feed pressure, improper RPM. | Ensure blade is sharp. Reduce feed pressure. Verify your biscuit joiner's RPM is within the blade's recommended range (max 14,000 RPM). |

| Blade wobbles or vibrates | Improper installation, loose arbor nut, damaged blade. | Ensure blade is correctly seated and arbor nut is tightened. Inspect blade for damage; replace if bent or cracked. |

| Difficulty cutting through material | Dull blade, incorrect blade for material type (though this blade is for wood), insufficient power from tool. | Clean or sharpen/replace blade. Ensure your biscuit joiner is adequately powered for the task. |

Specifications

| Attribute | Detail |

|---|---|

| Model Number | 240.008.04 |

| Brand | CMT ORANGE TOOLS |

| Material | Alloy Steel (Blade Body), Micrograin Carbide (Teeth) |

| Product Dimensions | 3.94"L x 0.16"W (approx. 100mm Diameter) |

| Color | Orange |

| Number of Teeth | 8 |

| Style | Industrial |

| Item Thickness | 4 Inches (Diameter) |

| Item Weight | 6 ounces (170 Grams) |

| Compatible Material | Wood |

| UPC | 664252006366, 758603313613 |

| Bore Diameter | 22mm |

| Cutting Angle | 15° |

| Tooth Configuration | 10° ATB (Alternate Top Bevel) |

| Maximum RPM | 14,000 RPM |

Warranty and Support

CMT carbide and carbide-tipped router bits and saw blades are designed, engineered, and manufactured to uncompromising standards for optimum cutting performance and maximum service life.

Warranty Information: If for any reason you are not satisfied with the performance of your CMT router bits or saw blades, and the bits were used for their recommended applications, you can return them to CMT for a full replacement. The warranty excludes dull, misused, damaged, and/or resharpened bits. CMT is not liable for damages to goods, property, or persons due to improper installation or misapplication of equipment.

For further support or inquiries, please contact CMT ORANGE TOOLS directly through their official channels or visit their website.