1. Introduction

This manual provides essential information for the safe and effective installation, operation, and maintenance of your Mile Marker H9000 Hydraulic Winch, Model 70-50080C. This winch is engineered for robust performance in vehicle recovery and towing applications, offering a 9,000 lb. capacity.

Key Features:

- 9,000 lb. (4082 kg) Line Pull Capacity

- Hydraulic Operation (Power Steering Pump Powered)

- 100% Duty Cycle

- Two-Speed Operation

- Free Spooling Capability

- Submersible Design for Underwater Use

- Corrosion Resistant Construction

- Stainless Steel Tie Bars & Fasteners

- Mechanical Lock

- Reversible Mounting Options

- Includes 100' Steel Cable and Roller Fairlead

2. Safety Information

Always prioritize safety when operating the winch. Failure to follow these instructions can result in serious injury or property damage.

- Read the Entire Manual: Understand all instructions and warnings before installation or operation.

- Wear Protective Gear: Always wear heavy-duty gloves, eye protection, and appropriate clothing.

- Inspect Equipment: Before each use, check the winch, cable, hook, and all accessories for damage or wear. Do not use damaged equipment.

- Maintain Safe Distance: Keep bystanders clear of the winching area. Never stand directly in line with the cable.

- Secure Vehicle: Ensure the vehicle is properly secured and braked before winching.

- Avoid Overloading: Do not exceed the winch's rated capacity.

- Proper Anchoring: Use a suitable anchor point capable of withstanding the pulling force.

- Cable Handling: Never handle the cable under tension. Always use a dampener (e.g., heavy blanket) over the cable during operation to reduce snap-back risk.

- Electrical/Hydraulic Safety: Ensure all hydraulic connections are secure and free from leaks.

3. Unpacking and Contents

Carefully unpack all components and inspect for any shipping damage. If any parts are missing or damaged, contact your dealer immediately.

Included Components:

- Mile Marker H9000 Hydraulic Winch

- 100' (30.5 m) Steel Cable

- Roller Fairlead

- Winch Hook

- Mounting Hardware (may vary)

4. Setup and Installation

Proper installation is crucial for the safe and efficient operation of your hydraulic winch. Consult a qualified professional if you are unsure about any steps.

4.1 Mounting the Winch

- Select a suitable mounting location on your vehicle, typically a winch bumper or cradle, capable of supporting the winch's weight and rated pulling capacity.

- Ensure the mounting surface is flat and strong enough to prevent flexing or damage during winching.

- Align the winch with the bolt pattern (4 bolt pattern, 4.5" x 10") and secure it using the provided high-grade hardware.

- Install the roller fairlead to guide the cable smoothly and reduce wear.

4.2 Hydraulic System Connection

The H9000 winch operates using your vehicle's power steering pump. This requires careful routing and connection of hydraulic lines.

- Identify the pressure and return lines from your vehicle's power steering system.

- Install the necessary hydraulic control valve (not included with the winch) into the power steering system.

- Connect the winch's hydraulic lines to the control valve according to the valve manufacturer's instructions. Ensure all connections are tight and free from leaks.

- Bleed the hydraulic system as per your vehicle's service manual to remove any air.

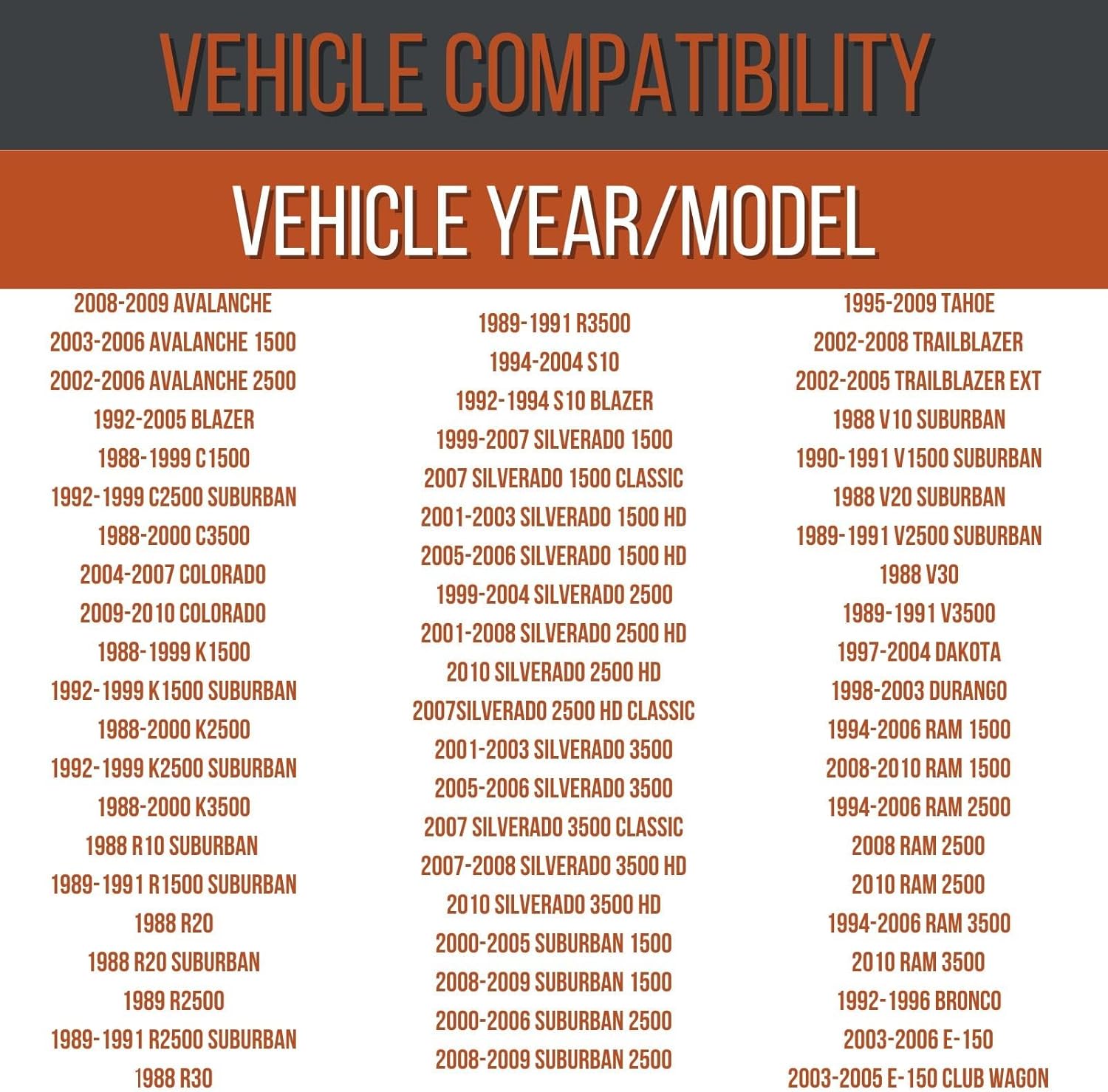

4.3 Vehicle Compatibility

The Mile Marker H9000 Hydraulic Winch is compatible with a wide range of vehicles. Refer to the following list for common compatible vehicle years and models. This list is not exhaustive; always verify fitment for your specific vehicle.

5. Operating Instructions

Follow these steps for safe and effective winch operation.

5.1 Pre-Operation Checklist

- Ensure the vehicle engine is running to provide hydraulic pressure.

- Inspect the winch, cable, and all rigging for damage.

- Confirm the anchor point is secure and appropriate for the load.

- Place a cable dampener over the cable, midway between the winch and the anchor point.

- Ensure all bystanders are clear of the winching area.

5.2 Free Spooling

To rapidly unspool the cable, engage the free spool lever. This disengages the winch drum, allowing the cable to be pulled out manually. Always ensure the free spool lever is fully disengaged before beginning a pull.

5.3 Winching Procedure

- Disengage the free spool and pull out enough cable to reach your anchor point.

- Secure the hook to the anchor point using a tree saver strap or shackle.

- Re-engage the free spool lever fully to lock the drum.

- Use the winch control (typically a remote pendant, not included) to slowly begin winching.

- Monitor the cable for proper spooling and tension. Avoid sudden jerks.

- Once the recovery is complete, release tension, disengage the hook, and carefully respool the cable under light tension.

5.4 Underwater Use

The H9000 winch is designed to be submersible and can be used underwater. After underwater use, it is recommended to thoroughly rinse the winch with fresh water and allow it to dry to prevent corrosion and maintain performance.

6. Maintenance

Regular maintenance ensures the longevity and reliable performance of your Mile Marker H9000 Hydraulic Winch.

- Cable Inspection: Regularly inspect the steel cable for kinks, frayed strands, or corrosion. Replace damaged cables immediately.

- Hydraulic System: Check hydraulic lines and fittings for leaks. Ensure the hydraulic fluid level in your power steering reservoir is adequate.

- Cleaning: Keep the winch clean from dirt, mud, and debris. Rinse thoroughly after use, especially after exposure to saltwater or mud.

- Lubrication: Periodically lubricate moving parts as recommended by the manufacturer.

- Fastener Check: Ensure all mounting bolts and fasteners are tight.

7. Troubleshooting

This section addresses common issues you might encounter with your hydraulic winch.

- Winch Not Operating:

- Check if the vehicle engine is running and providing hydraulic pressure.

- Verify that the hydraulic control valve is correctly engaged.

- Inspect hydraulic lines for blockages or severe leaks.

- Slow Winch Speed or Reduced Pulling Power:

- Ensure the power steering fluid level is correct.

- Check for air in the hydraulic system; bleed if necessary.

- Verify that the power steering pump is functioning correctly.

- Ensure the winch is not overloaded beyond its rated capacity.

- Cable Not Spooling Evenly:

- Always respool the cable under light tension to ensure even layering.

- Check the roller fairlead for obstructions or damage.

For issues not covered here, or if troubleshooting steps do not resolve the problem, contact Mile Marker customer support or a qualified service technician.

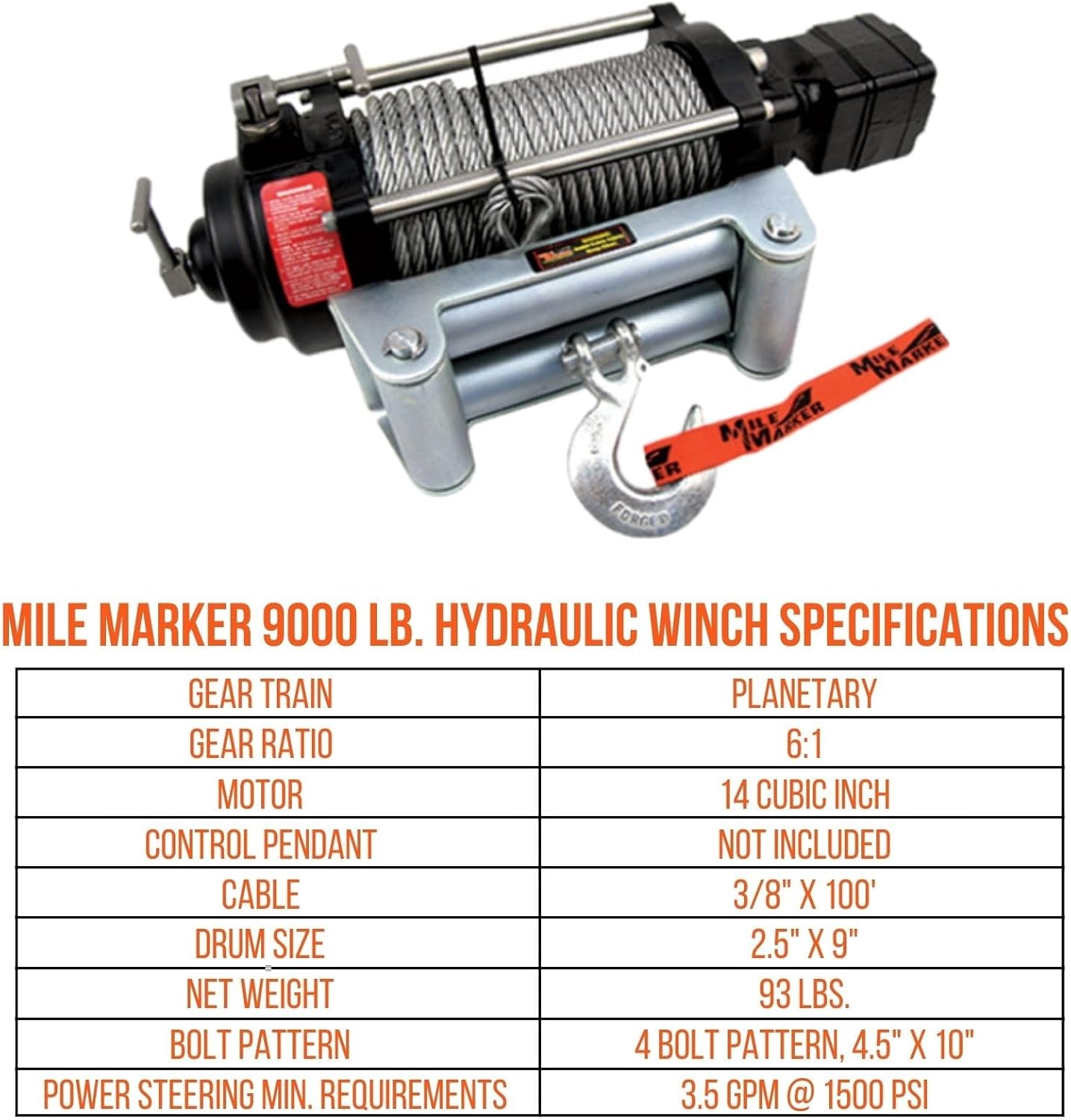

8. Specifications

8.1 General Specifications

| Feature | Specification |

|---|---|

| Manufacturer | Mile Marker |

| Model | 70-50080C (H9000 Series) |

| Item Weight | 93 lbs. (Net Weight) |

| Product Dimensions | 15 x 28 x 10 inches |

| Gear Train | Planetary |

| Gear Ratio | 6:1 |

| Motor | 14 Cubic Inch |

| Control Pendant | Not Included |

| Cable | 3/8" x 100' Steel |

| Drum Size | 2.5" x 9" |

| Bolt Pattern | 4 Bolt Pattern, 4.5" x 10" |

| Power Steering Min. Requirements | 3.5 GPM @ 1500 PSI |

8.2 Performance Specifications (3.5 GPM @ 1500 PSI)

| Layer of Cable | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Line Speed - Low Gear (ft/min) | 6.16 | 7.48 | 8.8 | 10.5 |

| Rated Pull (lbs.) - Low Gear | 9,000 | 7,300 | 6,200 | 5,400 |

| Line Speed - High Gear (ft/min) | 33.6 | 38.4 | 48 | 57 |

| Rated Pull (lbs.) - High Gear | 1,500 | 1,200 | 1,000 | 900 |

9. Warranty and Support

Mile Marker products are manufactured to high standards and are backed by a manufacturer's warranty. For specific warranty terms and conditions, please refer to the documentation included with your product or visit the official Mile Marker website.

Customer Support:

If you require technical assistance, have questions about installation, or need to report a warranty claim, please contact Mile Marker customer support directly. Contact information can typically be found on the manufacturer's website or product packaging.