Product Overview

The Powermatic Single-End Dovetailer, Model DT45, is a robust machine designed for cutting precise dovetails in various woodworking applications, including drawers and furniture components. It features a router spindle for adjustable dovetail height and can produce four distinct dovetail types with varying pitches. Manual eccentric clamping ensures secure workpiece handling.

Figure 1: The Powermatic Single-End Dovetailer DT45, a machine designed for precise dovetail joinery.

Safety Instructions

Always read and understand all safety warnings and instructions before operating the machine. Failure to follow the warnings and instructions may result in electric shock, fire, and/or serious injury.

- Wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and dust mask.

- Ensure the machine is properly grounded before use.

- Keep hands and fingers clear of the cutting area during operation.

- Disconnect power before performing any maintenance or adjustments.

- Maintain a clean and well-lit work area.

Setup and Assembly

The Powermatic DT45 Dovetailer requires proper setup to ensure safe and efficient operation. Refer to the included assembly diagrams for detailed steps.

Unpacking and Inspection

Carefully remove all components from the packaging. Inspect for any shipping damage. Report any damage immediately to the carrier and your dealer.

Placement

Place the machine on a stable, level surface capable of supporting its weight (approximately 345 pounds). Ensure adequate clearance around the machine for operation and maintenance.

Electrical Connection

The machine operates on 115/230V, 1Ph power. Ensure the electrical supply matches the machine's requirements. Connect the machine to a dedicated, grounded circuit.

Included Components

Verify all included components are present:

- Dovetail Machine

- Clamping Handles (with hex nuts) (x2)

- Set of Open-Ended Wrenches (8-10, 11-13, 12-14 and 17-19mm)

- Set of Hex Wrenches (1.5 to 6mm)

- Sample Dovetailed Board (x2)

Operating Instructions

The Powermatic DT45 is designed for efficient dovetail cutting. Familiarize yourself with the controls and features before operation.

Basic Operation

The machine features a magnetic starter for safe power control. Press the green "START" button to power on and the red "STOP" button to power off.

Figure 2: Magnetic starter for controlling machine power.

Adjusting Cutter Height

The cutter height can be adjusted from 3/16" to 3/4" to accommodate various board thicknesses and desired cutting depths. Use the adjustment mechanism to set the precise height.

Figure 3: Adjustment for cutter height, ranging from 3/16" to 3/4".

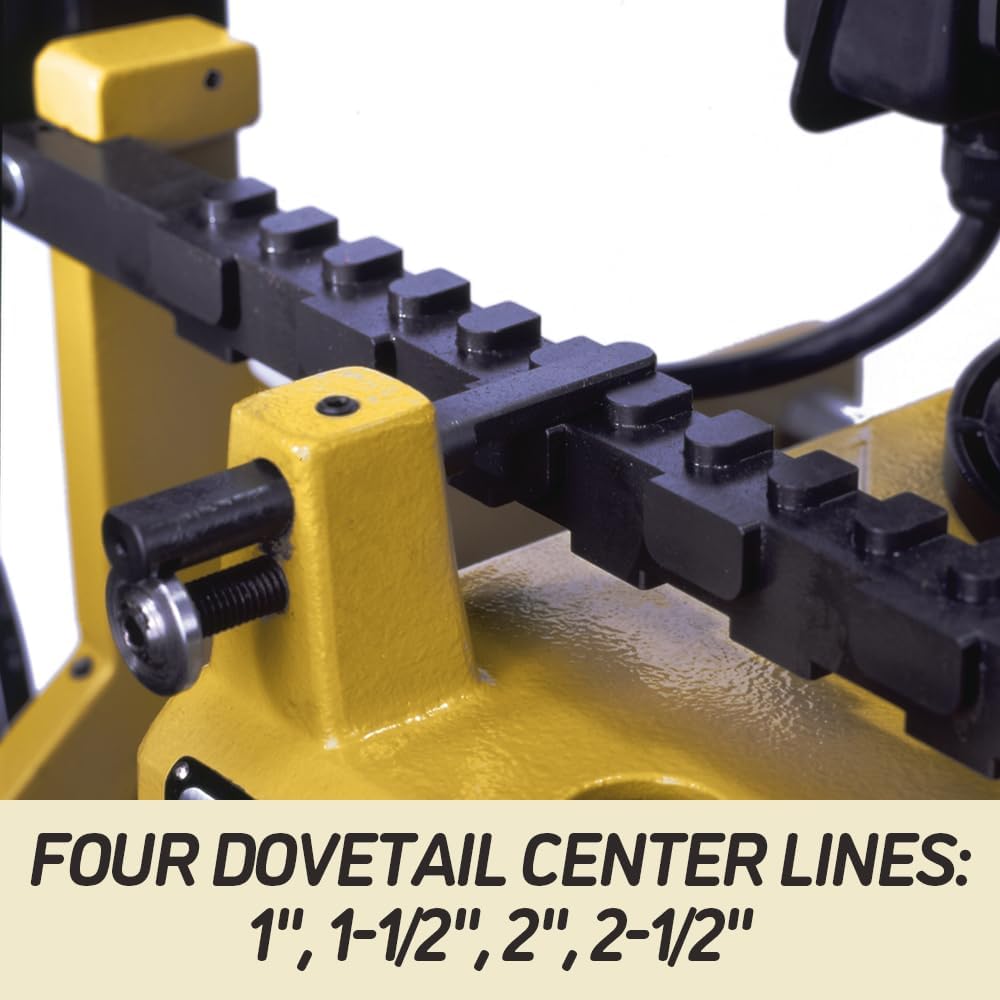

Utilizing Dovetail Center Lines

The machine offers four dovetail center lines at 1", 1-1/2", 2", and 2-1/2". These allow for creating custom dovetail appearances and spacing.

Figure 4: Dovetail center lines for varied joint spacing.

Eccentric Spindle Collet

The eccentric spindle collet is designed to accommodate resharpened cutters, ensuring continued precision and performance.

Figure 5: Eccentric spindle collet for cutter adjustments.

Workpiece Clamping

Locking and unlocking of workpieces is performed manually using an eccentric clamp, providing secure hold during the cutting process.

Figure 6: Visual representation of key features including clamping mechanism.

Maintenance

Regular maintenance ensures the longevity and optimal performance of your Powermatic DT45 Dovetailer.

- Cleaning: Regularly clean the machine, especially the cutting area and dust collection system, to prevent buildup of wood chips and dust. The built-in dust collection system is highly effective.

- Lubrication: Apply lubricant to moving parts as specified in the detailed maintenance schedule (refer to full manual for specifics).

- Cutter Sharpening/Replacement: Ensure cutters are sharp for clean cuts. Replace worn or damaged cutters promptly.

- Bearing Inspection: Precision linear carriage bearings are sealed to eliminate dust buildup, but periodic inspection for smooth operation is recommended.

Troubleshooting

This section provides solutions to common issues you might encounter with your DT45 Dovetailer.

| Problem | Possible Cause | Solution |

|---|---|---|

| Machine does not start | No power supply; Emergency stop engaged; Motor overload. | Check power connection; Reset emergency stop; Allow motor to cool and reset breaker. |

| Poor dovetail quality | Dull cutter; Incorrect cutter height; Loose workpiece. | Sharpen or replace cutter; Adjust cutter height; Ensure workpiece is securely clamped. |

| Excessive vibration | Unbalanced cutter; Loose components; Machine not level. | Inspect and balance cutter; Tighten all fasteners; Level the machine. |

Specifications

| Attribute | Value |

|---|---|

| Brand | Powermatic |

| Model Number | DT45 |

| Product Dimensions | 33"L x 33"W x 61"H |

| Voltage | 115 Volts |

| Power Source | Corded Electric |

| AC Adapter Current | 25 Amps |

| Item Weight | 345 Pounds |

| Material | Steel |

| Horsepower | 1 |

| Cutter Height Range | 3/16" to 3/4" |

| Dovetail Center Lines | 1", 1-1/2", 2", 2-1/2" |

| Construction | Cast iron and steel |

| Bearings | Precision linear carriage bearings, sealed |

Figure 7: The robust cast iron and steel construction of the DT45.

Warranty Information

The Powermatic Single-End Dovetailer DT45 comes with a 5-year warranty. This warranty covers defects in materials and workmanship under normal use and service. Please retain your proof of purchase for warranty claims.

Figure 8: The Powermatic 5-Year Warranty symbol.

Customer Support

For technical assistance, parts, or service, please contact Powermatic customer support. Visit the official Powermatic website for the most current contact information and additional resources.

Online Resources: Powermatic Store on Amazon