1. Introduction

This manual provides essential information for the safe and effective use of your wolfcraft 2144000 Mounted Stone Set. Please read these instructions carefully before operation and retain them for future reference.

Product Overview

The wolfcraft Mounted Stone Set is designed for grinding and finishing various materials, including metals, glass, ceramics, and plastics. The set includes five mounted stones of different shapes and one dressing stone for maintaining the abrasive surfaces.

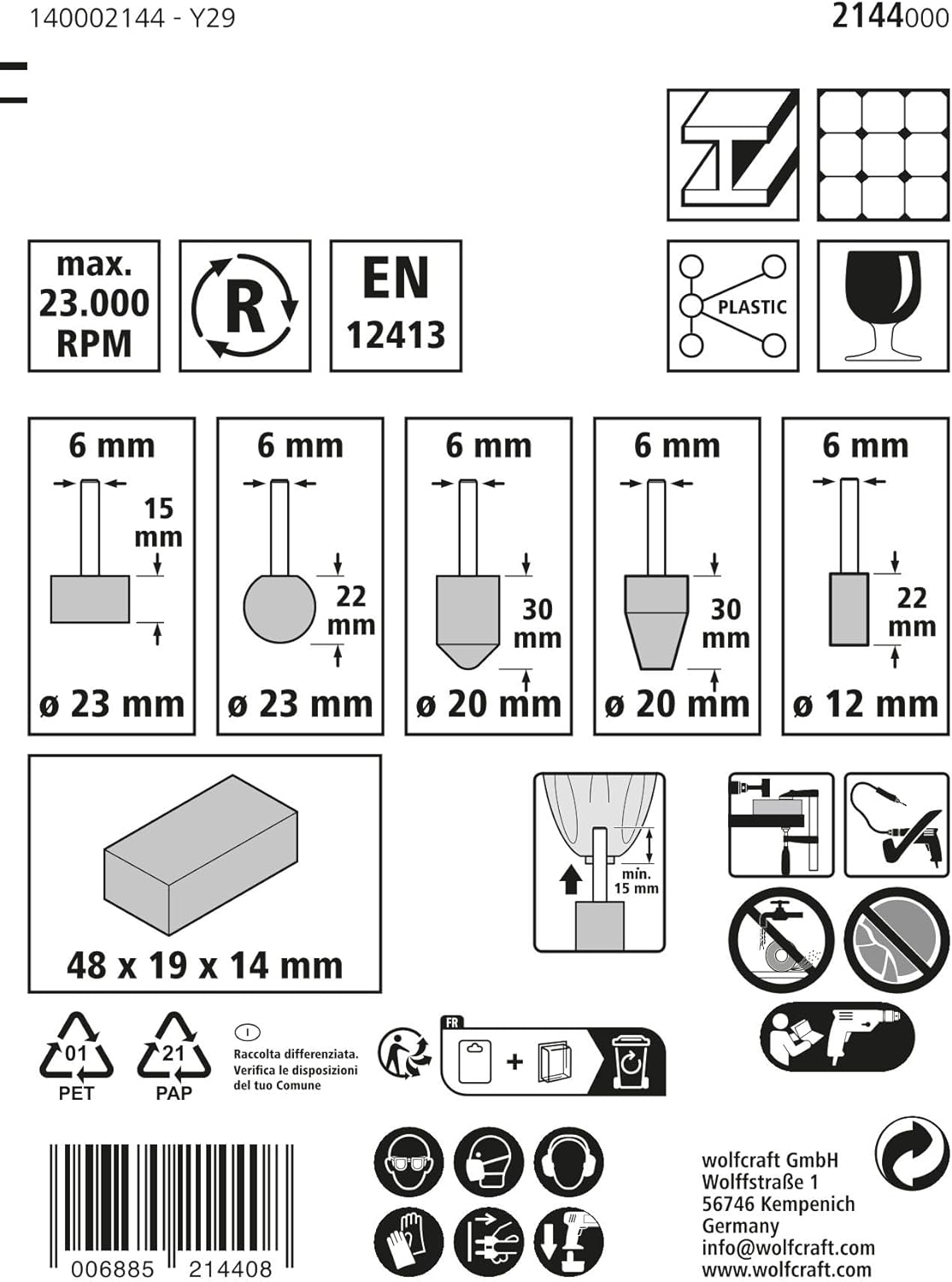

Figure 1: The wolfcraft 2144000 Mounted Stone Set, featuring five distinct grinding stone shapes and a dressing stone.

Included Components

- 5 x Mounted Grinding Stones (various shapes)

- 1 x Dressing Stone

2. Safety Instructions

Always observe the following safety precautions to prevent injury and damage to the product.

- Wear Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, and gloves when operating rotary tools with mounted stones.

- Check RPM Limits: Ensure the RPM of your rotary tool does not exceed the maximum RPM specified for the mounted stones (max. 23,000 RPM).

- Secure Workpiece: Always secure the workpiece firmly to prevent movement during operation.

- Inspect Stones: Before each use, inspect the mounted stones for any damage, cracks, or excessive wear. Do not use damaged stones.

- Proper Mounting: Ensure the mounted stone is securely fastened in the chuck of your rotary tool.

- Ventilation: Work in a well-ventilated area to avoid inhaling dust particles.

- Avoid Overheating: Do not apply excessive pressure, which can cause the stone or workpiece to overheat.

- Keep Clear: Keep hands and loose clothing away from rotating parts.

Figure 2: Safety symbols indicating the necessity of eye protection, hearing protection, and gloves during operation. Also shown are maximum RPM and individual stone dimensions.

3. Setup

Follow these steps to properly set up the mounted stones for use.

- Select the Appropriate Stone: Choose the mounted stone with the shape and grit suitable for your specific application and material.

- Insert into Rotary Tool: Loosen the chuck of your rotary tool (e.g., drill, die grinder). Insert the shaft of the mounted stone into the chuck, ensuring it is seated deeply and securely.

- Tighten Chuck: Firmly tighten the chuck to prevent the stone from slipping during operation. Verify that the stone is centered and runs true.

- Verify RPM: Confirm that your rotary tool's speed setting does not exceed the maximum recommended RPM of 23,000 for these stones.

4. Operating Instructions

Use the mounted stones for grinding, deburring, and shaping various materials.

General Usage

- Material Compatibility: Suitable for metals, glass, ceramics, and plastic materials.

- Application: Apply light, consistent pressure. Allow the stone to do the work. Excessive pressure can lead to premature wear, overheating, and potential damage to the stone or workpiece.

- Movement: Move the stone continuously across the workpiece to ensure even material removal and prevent grooving.

Figure 3: Example of a mounted stone in use, smoothing a circular opening in a workpiece, demonstrating its application for precise shaping.

Figure 4: A conical mounted stone deburring the interior edge of a metal pipe, illustrating its effectiveness for internal grinding and edge finishing.

5. Maintenance

Using the Dressing Stone

Over time, grinding stones can become clogged with material or develop an uneven surface, reducing their effectiveness. The included dressing stone is used to clean and reshape the grinding stones.

- Mount the Grinding Stone: Secure the grinding stone you wish to dress in your rotary tool.

- Activate Rotary Tool: Turn on the rotary tool at a moderate speed.

- Dress the Stone: Gently press the rotating grinding stone against the dressing stone. Move the grinding stone across the surface of the dressing stone to remove clogged material and expose fresh abrasive particles. This also helps to restore the original shape of the stone.

- Inspect: After dressing, inspect the grinding stone to ensure it is clean and has a renewed abrasive surface.

Storage

Store the mounted stone set in a dry place, away from moisture and direct sunlight, to prevent degradation of the abrasive material.

6. Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Poor grinding performance | Stone is clogged or worn out. | Use the dressing stone to clean and reshape. Replace if severely worn. |

| Excessive vibration | Stone not securely mounted or damaged. | Ensure stone is tightly secured in the chuck. Inspect for damage and replace if necessary. |

| Overheating of workpiece/stone | Excessive pressure or incorrect RPM. | Reduce pressure. Verify RPM is within recommended limits. Allow cooling periods. |

7. Specifications

| Feature | Detail |

|---|---|

| Model Number | 2144000 |

| Material | Aluminum Oxide |

| Grit Type | Medium (Grit Number: 120) |

| Number of Pieces | 6 (5 mounted stones, 1 dressing stone) |

| Maximum RPM | 23,000 RPM |

| Compatible Devices | Rotary tools (e.g., drills, die grinders) |

| Item Weight | 0.352 ounces (approx. 10g) |

| Product Dimensions (approx.) | 0.24"L x 0.24"W (individual stone dimensions vary) |

| UPC/GTIN | 04006885214408 |

8. Warranty and Support

wolfcraft products are manufactured to high-quality standards. For information regarding warranty terms and conditions, please refer to the official wolfcraft website or contact customer support.

Contact Information

wolfcraft GmbH

Wolffstraße 1

59746 Kempenich

Germany

Email: info@wolfcraft.com

Website: www.wolfcraft.com

Figure 5: wolfcraft's commitment to European manufacturing and recognition as a major German brand.