ACT 343 ProClick Constant Temperature Controller

ACT 343 ProClick Constant Temperature Controller

Owner’s Manual

ACT 343 ProClick Constant Temperature Controller

NOTE!

The product may only be used if you have fully read and understood these operating instructions. The manual is also available on the AFRISO websites in the Internet.

WARNING!

The product may only be mounted, commissioned and disposed of by qualified, speciall trained staff. Electrical work should always be entrusted to a qualified electrician.

Alterations performed by unauthorized staff may cause a threat and are forbiddefor safety reasons.

The product is powered by 230 V AC. This may cause severe injuries or death.

Do not let the product go into contact with water.

Do not alter the product in any way.

Before mounting the product please read the manual of the mixing valve.

APPLICATION

The ACT 343 ProClick constant temperature controller is used in heating systems in order to maintain a constant temperature of the heating medium behind a rotary mixing valve. It can be mounted on both 3- and 4-way valves. The wide temperature range (10÷90°C) combined with a clear, colour display allows for convenient automation and control of the operation of the heating system.

SCOPE OF DELIVERY

- ACT 343 ProClick constant temperature controller equipped with a temperature sensor with a pipe mounting adapter, a knob with a double-sided scale (“from 0 to 10” and “from 10 to 0”) and an electric cable with a plug.

- Instruction manual.

- Mixing valve mounting manual.

CONSTRUCTION OF THE ACT ProClick CONSTANT TEMPERATURE CONTROLLER MOUNTING OF THE ACT ProClick CONSTANT TEMPERATURE CONTROLLER

MOUNTING OF THE ACT ProClick CONSTANT TEMPERATURE CONTROLLER

Mounting and dismounting the controller on the ARV Vario ProClick mixing valve To mount or dismount the controller, press and hold the ProClick system pushbutton (1), and then slide the actuator on or off the valve spindle (2). The controller can be mounted on the valve in four different positions (Fig. 3), the display will always automatically orient itself horizontally. The blue ring with indicator must point upwards. If it does not, pull off the knob and blue ring, then mount it back with the indicator pointing upwards.

The controller can be mounted on the valve in four different positions (Fig. 3), the display will always automatically orient itself horizontally. The blue ring with indicator must point upwards. If it does not, pull off the knob and blue ring, then mount it back with the indicator pointing upwards.

The temperature sensor should be mounted behind the valve by using the adapter included, or a specially prepared sleeve.

Factory mounted plug to connect the power to the device.

CONFIGURING THE ACT ProClick CONSTANT TEMPERATURE CONTROLLER

- Initiating the controller settings

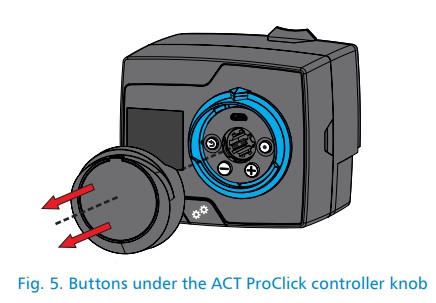

Take off the knob (Fig. 5) and then press and

and buttons for 5 seconds.

buttons for 5 seconds.

- Diagram selection

Select the appropriate diagram in accordance with the mixing valve mounting position in the system. The available diagrams are: mixing valve mounted on the supply pipe (Fig. 6) or mixing valve mounted on the heat source return pipe (Fig. 7). If the controller is mounted on a 4-way valve, select the diagram showing mounting on the return pipe (Fig. 7). Then, select the rotation direction and install the temperature sensor as show in Fig. 8. - Opening direction

After selecting the appropriate diagram, the next step is to select the direction of opening the valve. When the ACT ProClick constant temperature controller is mounted on the supply pipe, to maintain a constant temperature of the heating medium entering the system, the direction of operation of the controller should be chosen to ensure that rotating the valve sleeve in the chosen direction increases the flow of medium from the heat source into the system. The setting indi- cates controller operation to the right – clockwise. The

setting indi- cates controller operation to the right – clockwise. The  setting indicates controller operation to the left – counterclockwise.

setting indicates controller operation to the left – counterclockwise. - Temperature setting

In the next step, you have to select the minimum temperature (Tmin), below which the valve will be 100% open to the heat source. Then, you have to select the maximum temperature (Tmax), above which the valve will completely cut off the flow of the hot medium from the heat source, and open fully to the colder medium flow from the return pipe. Then, you need to select the mixed medium temperature you choose to maintain, between Tmin and Tmax. The icon indicates exiting the settings and returning to the starting screen.

icon indicates exiting the settings and returning to the starting screen. - Selecting the scale

In the last step, you need to select the right scale, either “0 to 10” or “10 to 0”, corresponding to the chosen diagram (Fig. 6, Fig. 7, Fig. 8). To change the scale, you need to lift up the plate, and put it on again facing the other side.

Fig. 6. Diagram with the ARV Vario ProClick mixing valve mounted on the supply pipe to mainta- in a constant temperature of the medium in the system

Fig. 6. Diagram with the ARV Vario ProClick mixing valve mounted on the supply pipe to mainta- in a constant temperature of the medium in the system Fig. 7. Diagram with the ARV Vario ProClick mixing valve mounted on the return to the heat source, in order to protect the heat source against low-temperature corrosion

Fig. 7. Diagram with the ARV Vario ProClick mixing valve mounted on the return to the heat source, in order to protect the heat source against low-temperature corrosion Fig. 8. Diagram with a 4-way mixing valve mounted in order to protect the heat source against low-temperature corrosion

Fig. 8. Diagram with a 4-way mixing valve mounted in order to protect the heat source against low-temperature corrosion

The required mixed temperature setting can also be changed through pressing and holding both the![]() and

and![]() buttons for 1 second, without having to go through the whole menu.

buttons for 1 second, without having to go through the whole menu.

DEVICE MENU MAP

OPERATING THE ACT ProClick CONSTANT TEMPERATURE CONTROLLER

- Mode of operation of the ACT constant temperature controller

Switching from automatic to manual mode is done by pressing the manual mode pushbutton.

When the pushbutton is in the upper position, the controller is in the automatic mode. When the pushbutton is pressed down, manual operation, meaning freely turning the controller knob, is possible. Additionally, the symbol

When the pushbutton is in the upper position, the controller is in the automatic mode. When the pushbutton is pressed down, manual operation, meaning freely turning the controller knob, is possible. Additionally, the symbol![]() is displayed during manual operation.

is displayed during manual operation.

2. Icon description ![]()

| – heating mode | |

| – valve turning to the left | |

| – valve turning to the right | |

| – return temperature sensor |

| – supply temperature sensor | |

| – manual mode activated | |

| – required mixed temperature | |

| – sensor malfunction |

Fig. 10. Description of the symbols displayed on the controller

TECHNICAL PARAMETERS

| Parameter/piece | Value / material |

| Torque | 6 Nm |

| Temperature range | 10 / (90 deg) * C |

| Rotation angle | 90 deg |

| 90 deg turning time | 120 5 |

| Power voltage | 230 V AC |

| Ambient temperature range | 10 / (50 deg) * C |

| Power consumption | max 3 W |

| Housing protection class | IP42 |

| Dimensions (HWD) | 85.5 * 97 * 99 mm |

| Weight | 800 g |

| Housing material | black, PC |

| Mode of operation | heating |

| Power cable length | 2m, with plug |

| Temperature probe cable length | 1m, pipe contact adapter included |

| Thermocouple dimensions | 10×04 mm |

| Control algorithm | PID |

APPROVALS AND CERTIFICATES

AFRISO Sp. z o.o. hereby declares that the product complies with:

- LVD directive: 2014/35/EU,

- EMC directive: 2014/30/EU,

- RoHS II directive: 2011/65/EU + Annex II 2015/863/EU.

The full text of the EU Declaration of Conformity is available at the following web address: www.afriso.pl.

MAINTENANCE

The ACT ProClick constant temperature controller is a maintenance-free product.

DECOMISSIONING, DISPOSAL

- Disconnect the power supply.

- Dismount the device.

- Dispose of the product according to local directives and guidelines. Electronic parts and batteries should not be disposed of with household waste.

Return the product to the appropriate collecting point or to the manufacturer’s or distributor’s collecting point.

WARRANTY

Product guarantee in accordance with the general conditions of sale and delivery.

CUSTOMER SATISFACTION

For AFRISO customer satisfaction is paramount. If you have any questions, suggestions or product problems, please contact us.

AFRISO Sp. z o.o.

AFRISO Sp. z o.o.

Szałsza, ul. Kościelna 7

42-677 Czekanów

www.afriso.pl

Customer Service Team

tel. +48 (0) 32 330 33 50

info@afriso.pl

ACT 343 ProClick constant temperature controller

Documents / Resources

|

AFRISO ACT 343 ProClick Constant Temperature Controller [pdf] Owner's Manual ACT 343 ProClick Constant Temperature Controller, ACT 343, ProClick Constant Temperature Controller, Constant Temperature Controller, Temperature Controller, Controller |