Introduction

This manual provides instructions for the safe and efficient operation and maintenance of your VEVOR 5 Gallon / 21 Liter Alcohol Still. This distiller is designed for home use to produce various spirits, distilled water, and essential oils. Please read this manual thoroughly before assembly and operation.

Image: VEVOR 5 Gallon Alcohol Still with main components and accessories.

Safety Precautions

- Always operate the still in a well-ventilated area.

- Ensure all connections are tight to prevent steam leaks.

- Monitor the temperature closely during operation.

- Keep flammable materials away from the heating source.

- Do not leave the still unattended during operation.

- Always allow the still to cool completely before disassembling or cleaning.

- Be aware of local regulations regarding alcohol distillation.

Package Contents

Before assembly, verify that all components are present:

- 1 x Fermentation Barrel (Boiler Barrel)

- 1 x Condenser Barrel (Thumper Keg)

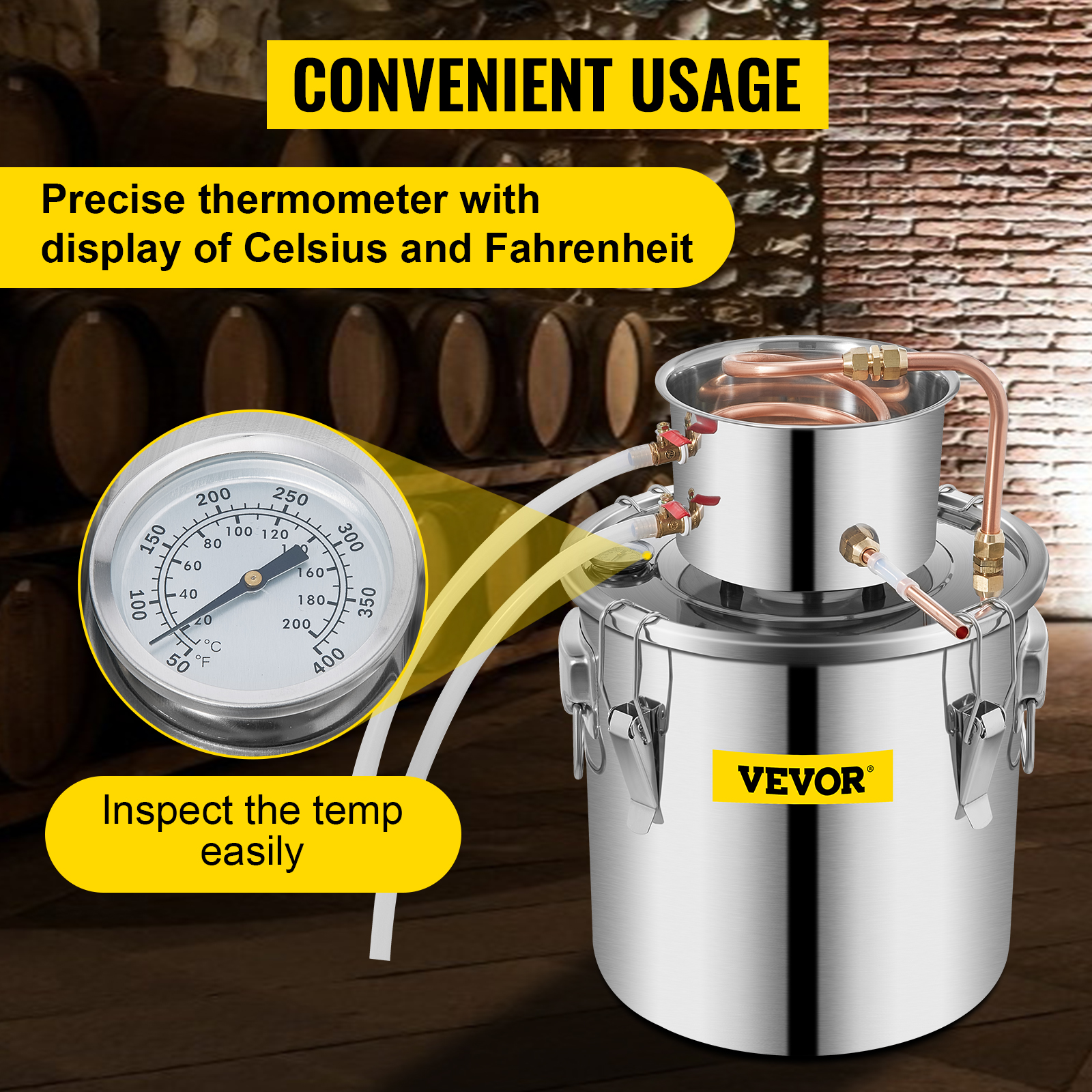

- 1 x Thermometer (Dual display Celsius/Fahrenheit)

- 1 x One-way Air Evacuation Valve

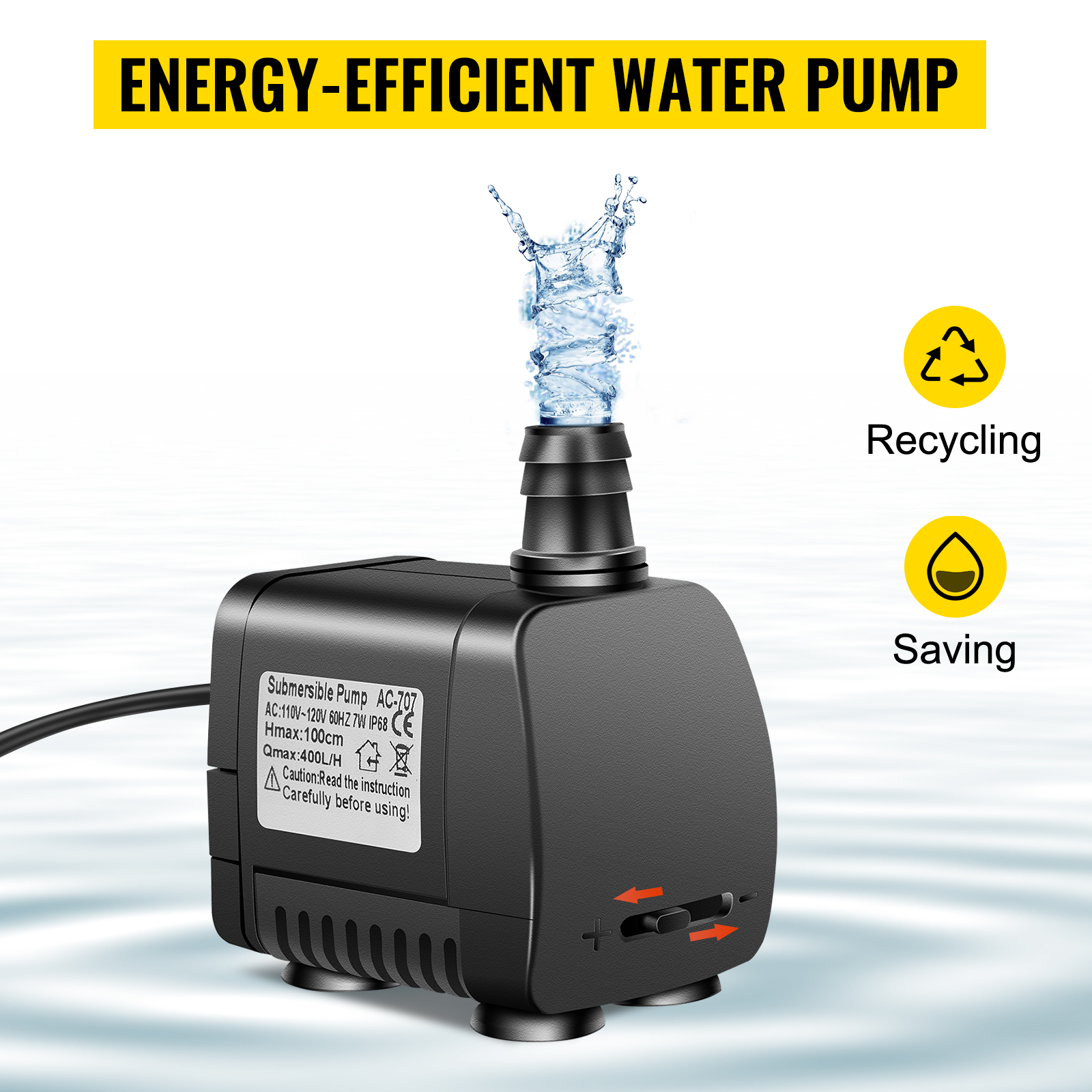

- 1 x Circulating Water Pump

- Silicone Tubes for water circulation

- Silicone Sealing Ring

- Set of Accessories (including sealing buckles, rubber pad)

- 1 x User Manual (this document)

Image: All components included in the package, such as the pump, airlock, thermometer, and tubing.

Setup and Assembly

- Prepare the Boiler Barrel: Ensure the 5-gallon fermentation barrel is clean.

- Install Thermometer: Insert the thermometer into its designated port on the lid of the boiler barrel. Ensure it is securely fastened.

- Connect Condenser Barrel: Place the condenser barrel on top of the boiler barrel. The copper coil should be positioned inside the condenser barrel.

- Secure Sealing:

- Place the silicone sealing ring around the rim of the boiler barrel before placing the lid (with the condenser attached).

- Use the four upgraded sealing buckles to tightly secure the lid to the boiler barrel. This ensures a strong, leak-proof seal.

- Insert the one-way air evacuation valve into its port on the lid.

Image: Components for reliable and high-strength sealing, including the built-in sealing ring, one-way air evacuation valve, thickened boiler barrel, sealing bucket, and portable handle.

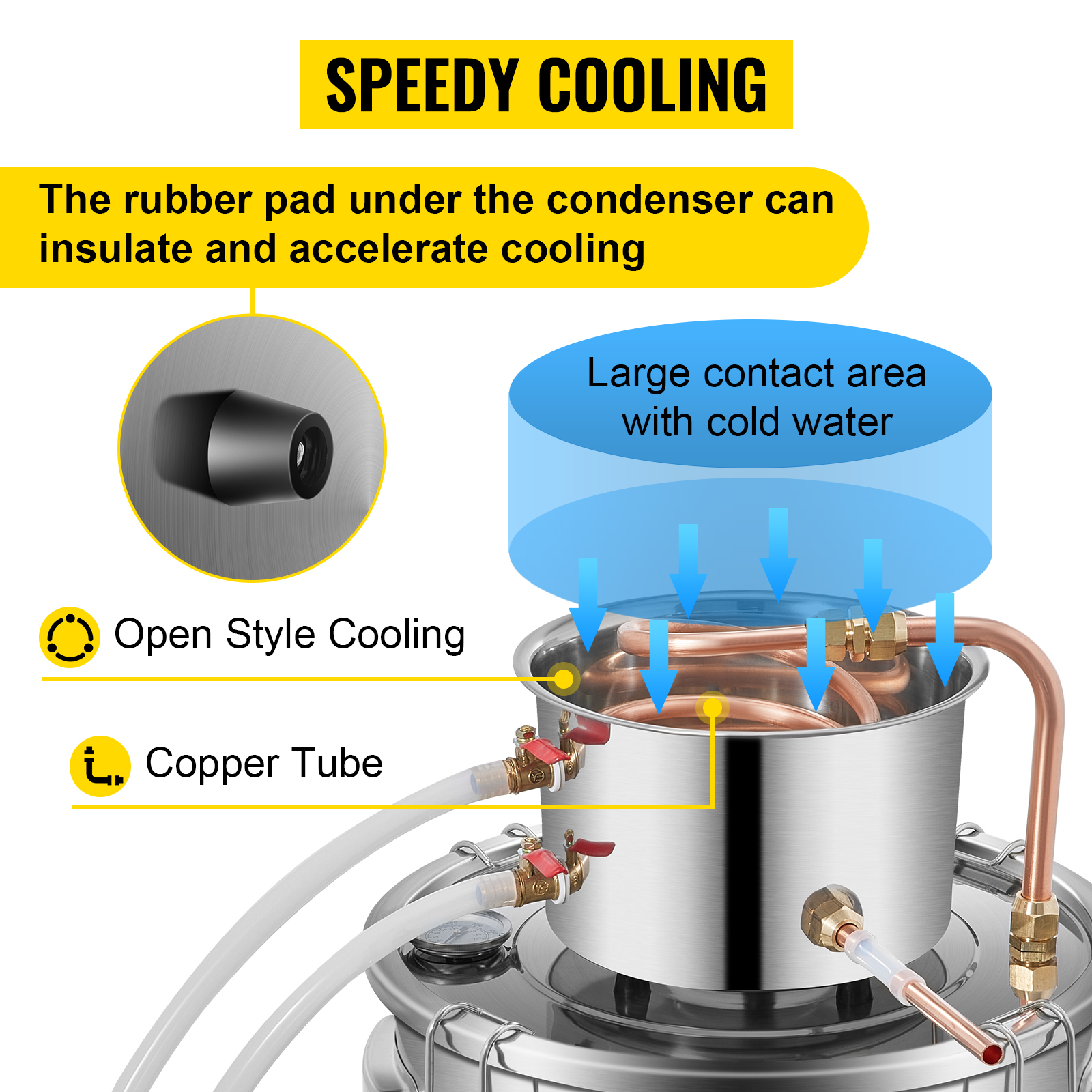

- Connect Water Pump for Cooling:

- Attach the silicone tubes to the inlet and outlet ports of the condenser barrel.

- Connect the circulating water pump to the lower inlet tube.

- Place the water pump in a container of cold water. The upper outlet tube should return water to this container, creating a closed-loop cooling system.

Image: Illustration of the speedy cooling system, highlighting the copper tube and open-style cooling with large contact area for cold water.

Image: The energy-efficient water pump, designed for recycling and saving cooling water.

Operating Instructions

- Fill the Boiler Barrel: Pour your raw material (e.g., fermented wash, water for distillation) into the 5-gallon boiler barrel. Do not overfill; leave adequate headspace.

- Apply Heat: Place the assembled still on a suitable heat source. This still is compatible with various heating methods, including coal stoves, gas stoves, and firewood.

Image: Examples of compatible heating methods: coal gas, firewood, gas stoves, and coal stoves.

- Start Cooling System: Once heating begins, activate the circulating water pump to ensure a continuous flow of cold water through the condenser barrel. The rubber pad under the condenser helps insulate and accelerate cooling.

- Monitor Temperature: Continuously monitor the temperature using the built-in thermometer. The thermometer displays both Celsius and Fahrenheit.

- For alcohol distillation, cooling water circulation is typically required when the temperature reaches approximately 80°C (176°F).

- Maintain the desired temperature range for your specific distillation process.

Image: The precise thermometer with dual display (Celsius and Fahrenheit) for easy temperature inspection.

- Collect Distillate: As vapor condenses in the copper coil, the liquid distillate will exit the condenser. Collect it in a suitable container.

- Shut Down: Once distillation is complete or the desired volume is collected, turn off the heat source and the water pump. Allow the still to cool down completely before handling.

Maintenance and Cleaning

- After Each Use:

- Once the still has cooled, disassemble all components.

- Thoroughly clean the interior of the boiler barrel, condenser barrel, copper coil, and all tubing with warm water and a mild, food-safe detergent.

- Rinse all parts thoroughly to remove any detergent residue.

- Ensure all parts are completely dry before reassembly or storage to prevent corrosion.

- Water Pump Maintenance: Periodically check the circulating water pump for any blockages or debris. Clean as necessary to ensure efficient operation and longevity.

- Sealing Ring Inspection: Inspect the silicone sealing ring for any signs of wear, cracks, or damage. Replace if necessary to maintain a tight seal.

- Storage: Store the still and its components in a clean, dry place.

Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Steam leaks from connections | Loose connections, damaged sealing ring | Tighten all buckles and connections. Inspect and replace the silicone sealing ring if damaged. |

| Inefficient cooling / Low distillate output | Insufficient cold water flow, water pump malfunction, high ambient temperature | Ensure water pump is operating correctly and water reservoir is sufficiently cold. Check for kinks in tubing. Increase water flow if possible. |

| Thermometer not reading correctly | Improper installation, faulty thermometer | Check thermometer installation. If issue persists, thermometer may need replacement. |

| No distillate produced | Insufficient heat, raw material not fermenting, leaks | Increase heat. Ensure raw material is properly prepared. Check for leaks as described above. |

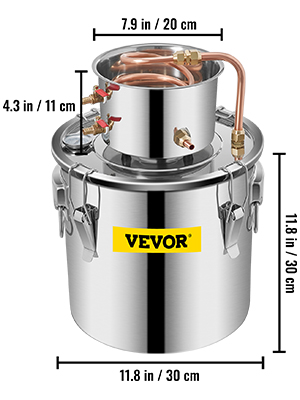

Specifications

| Feature | Detail |

|---|---|

| Brand Name | VEVOR |

| Material | Stainless Steel + Red Copper |

| Boiler Barrel Capacity | 5 Gal / 19 L |

| Boiler Barrel Size | 11.8" x 11.8" / 30 x 30 cm |

| Condenser Keg Capacity | 0.92 Gal / 3.5 L |

| Condenser Keg Size | 7.9" x 4.3" / 20 x 11 cm |

| Barrel Thickness | 0.03" / 0.7 mm |

| Copper Coil Diameter | 0.39" / 10 mm |

| Product Weight | 10.3 lbs / 4.68 kg |

| Heating Methods | Coal stoves, Gas stoves, Firewood, etc. |

| Applications | Whiskey, Wine, Brandy, Rum, Tequila, Vodka, Distilled Water, Essential Oils, etc. |

Image: Visual representation of product dimensions and various applications like wine, whisky, and essential oils.

User Tips

- For optimal cooling, ensure the water in your circulating pump reservoir is kept as cold as possible. Adding ice can help maintain lower temperatures.

- Always perform a sacrificial run (distilling plain water) before your first actual run to clean out any manufacturing residues and test the system for leaks.

- When distilling alcohol, pay close attention to the thermometer. The temperature directly impacts the quality and type of distillate collected.

- The 5-gallon capacity is ideal for small to medium batches, suitable for personal use or small gatherings.

Warranty and Support

For detailed warranty information, product support, or to purchase replacement parts, please refer to the official VEVOR website or contact VEVOR customer service directly. Keep your purchase receipt for warranty claims.