Manual or Fully Automatic Transfer System

Manual or Fully Automatic Transfer System

OPERATOR’S MANUAL

ATS-385

ATS-385

Automatic Transfer Switch Control Unit

CM-MI 125 Automatic Switch Control Unit

| Frame | Circuit Breaker | Selectable Amps | System is frame & size dependent, eg. the selection must be from the same frame size. Select any MCCB combination 230 – 400V Network |

| CM-M1 125 | G37D | 15 – 125 A | |

| CM-MI 250 | F37D | 150 – 250A | |

| CM-MI 400 | K5OD | 250 – 400 A | |

| CM-MI 800 | L65D | 500 – 800A |

- MCCB styled electrical change over with manual option

- Easy to read mechanical status. Compatible with most ATS controllers

- Fully built and pre-wired to accept mains and controller interface

- Customer selected combinations

- Factory assembled and tested

- Factory fitted combined Busbars on load side

- Electrical locking system with factory fitted MCCB, Aux Circuit

- 3P System standard (4 Pole optional*)

Motor specifications

200 – 240 VAC (50 / 60Hz)

Uzi AC 750V

Ute 220V

* Please select breakers for assembly

Complete System Assembly*

Complete System Assembly*

INTRODUCTION

Preliminary Comments and Safety Precautions

The manual covers installation, operation and maintenance of the ATS-385 Automatic Transfer Switch PLC Controller. This manual is for use by authorized and qualified personnel only.

WARNING

High voltage will cause severe injury or death

Overview

Transfer switches protect critical electrical loads against loss of power. A_ standby (emergency) generator backs up the normal grid power. The transfer switch connects Normal and Standby source supply to the load. When power is lost from Normal source, the transfer switch transfers the load to the standby source. After power is restored, the ATS will transfer the load back to Normal source.

Product Overview

The ATS-385 is a multifunction programmable logic automatic transfer switch controller. Suitable for 1 phase and 3 phase system, including all necessary monitoring and protections.

Controller’s features :

- Microprocessor based & Polycarbonate panel.

- Membrane switch button designed. *1

- Compact size with user-friendly LED display.

- Programmable for cycle-mode or fix-mode displays for 3-phase and 1-phase voltages and frequencies.

- All programming and operations can be configured on the front panel.

- Monitors Normal and Standby power for Over /Under voltage anomalies.

- Monitors Normal and Standby power for Over /Under frequency anomalies.

- Exercise with or without load.

- 1 week to 4 weeks automatic scheduled exercise / testing.

- Transfer failure output signal.

- Pre-alert warning signal output for transferring operation.

- Pre-alert warning signal output for scheduled automatic Exercise / testing.

- Compatible with most ATS switches on the market.

- Communication Port for Remote Monitoring and Control Options. (USB / RS485 / Ethernet / WI-FI modules SIM Card).

- Program on-site or from remote (mobile) device (PC, Smartphone).

- Auto-saved settings (memory preserved throughout all power disconnects and resets).

- Front panel display provides source status and fail alarm indications.

Functions / Features

The primary function of ATS-385 controller is to monitor Normal / Standby power and to provide seamless automatic transfer of load.

Operational Simplicity

From installation to programming and to usage, the ATS-385 controller is designed with operational simplicity in mind. The user-friendly front panel interface simplifies routine operation, programming and setting adjustments.

Standard Features

All logic settings for different ATS’s_ are preprogrammed and_ stored in_ its non-volatile random-access memory (NVRAM), this memory retains its information when power is turned off. Some features and set points are user adjustable.

Feature 1 : Time Delay Emergency to Normal (TDEN)

TDEN delays the transfer from the emergency source to the normal Source to permit stabilization of the normal source before retransfer is made. Timing begins when the normal source becomes available. (Refer to program table line 3)

Adjustable TDEN time range : 00 999 sec.

Feature 2 : Time Delay Normal to Emergency (TDNE)

TDNE delays the transfer from normal to emergency to permit stabilization of the generator before the retransfer is made. Timing begins when the standby source becomes available. (Refer to program table line 4)

Adjustable TDEN time range : 00 250 sec.

Feature 3 : Time Delay Engine Start (TDES)

The TDES Time (Delays Engine Start) this timer prevents nuisance start because of momentary electrical glitches. If power normalizes before the countdown ends, the controller skips the engine start and resets the timer. (Refer to program table line 5)

Adjustable TDES time range : 00 30sec.

Feature 4 : Time Delay Engine Cool-down (TDEC)

TDEC permits the generator to run unloaded after the ATS retransfer back the load to Normal source. Timing begins when the ATS connects back to Normal source. (Refer to program table line 6)

Adjustable TDEC range : 00 250 sec.

Feature 5 : Time Delay Center OFF Position

This timer temporally stops the switch in the center OFF position (completely cut off) before proceeding to Normal source. (Refer to program table line 7)

Adjustable time delay range : 00 99sec.

Feature 6 : Full Phase Over / Under Voltage and Loss of Phase Sensing

The controller monitors full phase output voltage from Normal and Standby source. The user can program over & under voltage window. (Refer to program table line 8, 9, 10, 14, 15 & 16)

O/V adjustment range : 390 490 Vac

O/V reset value : -10 Vac (Not adjustable)

U/V adjustment range : 300 410 Vac

U/V reset value : +10 Vac (Not adjustable)

Feature 7 : Under / Over Frequency Sensing

The controller monitors Normal and Standby source frequency. The client can set the over & under frequency range. (Refer to program table line 11, 12, 13,17, 18 & 19)

O/F adjustable range : 51 75 Hz

O/F reset value : -1 Hz (Not adjustable)

U/F adjustable range : 40 59Hz

U/F reset value : -1 Hz (Not adjustable)

Feature 8 : Programmable exerciser

It can be set to exercise one time per week to one time every 4 weeks on any day and time, with or without load. The length of the exercise is also set. (Refer to program table line 23, 24, 25, 26 & 27)

Feature 9 : Failure Warning Output

The controller also has one dry contact that can be set to react to one of four warning. (Refer to program table line 30)

- Transfer failure warning

- Pre-transfer warning

- Pre-test / exercise warning

- When ATS is in emergency position warming

NOTICE

ATS-385 provides one auxiliary contact for external output signal for Transfer Failure, Pre-transfer or Pre-exerciser alarm output.

Feature 10 : Controller Panel Lighting Test

This checks the LED lights. Press the OFF button twice, all panel LEDs must light up.

OPERATOR PANEL

General

Get acquainted with the ATS-385 :

- Front Display Window

- Function Buttons

- Panel LEDs Display

Display Window

The ATS-385 controller has a four-digit, seven-segment displayer to monitor all parameters, setting and messages.

The screen display’s :

- Full phase voltage / frequency display

- Current Time HH : MM (In OFF only)

- Time delay countdown display

- Program setting parameter display

The front panel employs five membrane switch buttons.

Increase (▲) Button

In AUTO Mode, each press of the up (▲) button changes the display to the next phase voltage reading.

However, when programming every press of the up (▲) button increases the displayed parameter by a single unit. If held, the up (▲) button continues to scroll.

Decrease (▼) Button

In AUTO Mode, each press of the down (▼) button changes the display between voltage, duty time and frequency.

However, when programming every press of the down (▼) button decreases the displayed parameter by a single unit. If held, the down (▼) button continues to scroll.

AUTO Button

When selecting the AUTO button, the ATS-385 runs in automatic mode (AUTO) lighting the corresponding LED to indicate the _ selection. The _ controller automatically starts the generator, transfer and retransfers from Normal to Standby source as commanded by the features supplied and the preprogrammed setting.

TEST Button

Pressing the TEST button simulates a power failure In TEST the generator starts and begins a preprogrammed execution and testing sequence made with or without loading the generator. (Refer to program line 28)

OFF Button

Pressing the OFF again, turns the ATS-385 OFF engaging a flashing red LED instantly disabling all functions and the screen shows the current time.

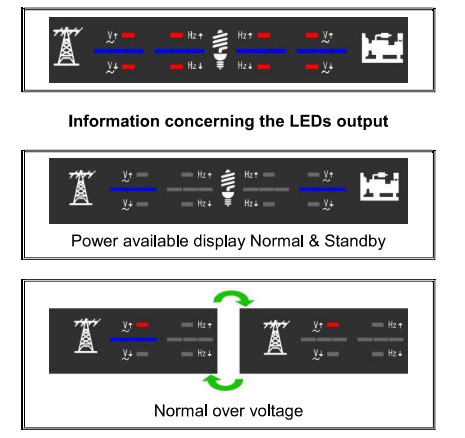

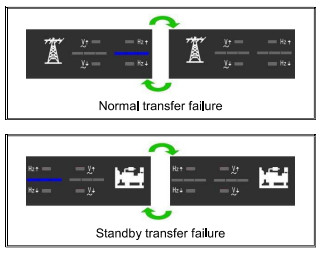

Panel LED Outputs

Eight individual red and blue LEDs light bars perform or indicating each function.

OPERATION

General

The five functions of the ATS-385 :

- AUTO Mode

- OFF Mode

- Manual Test Mode (TEST)

- Programming Instruction

- Remote Communication Instruction

The practical use of each operation under each category will be explained in this section. It is assumed that prior sections are understood, and the operator has a basic understanding of the hardware.

AUTO Mode

The AUTO mode provides automatic engine start, stop, and power transfer and retransfers from source to source as_ dictated by the values previously programmed.

The ATS-385 constantly monitors the condition of both Normal and Standby source.

OFF Mode

In OFF mode, the ATS-385 disables all the transfers and protection functions with all LED indicators off leaving the display screen only showing the time. User can test the LEDs by pressing the OFF button twice. Check and reset the clock every year. The wrong time can affect the schedule exerciser. Without power, the controller can maintain the clock working for up to a week.

However, when programming, the OFF button allows you to move to the next program line and then change the values for that line using down (▼ ) and up (▲) buttons. 3.4 Manual Test Mode (TEST)

Pressing TEST simulate a loss of Normal power source.

Permitting the controller to start the engine and carry out a power transfer. TEST can be with load or without load.

To end, press the AUTO button. If Normal power is available, the controller transfer back to Normal and the engine follow the program shutdown procedure to stop the generator. However, by pressing the OFF button, the transfer switch remains in its current position stopping the engine, and bypassing all time delays.

Programming Instruction

Program the controller from the front faceplate.

To start, set the controller to OFF and press & hold the OFF button for 4 seconds. The word “Vr” appears on the display for 2 seconds, showing the software version.

You are now ready to. start the line-by-line programming sequence. Always press the OFF button to move to the next line. To change the parameter, on each line use the up (▲) and down (▼) arrows. Repeatedly pressing the up (▲) or down (▼) button, changes the displayed by one. To change faster, hold the buttons down.

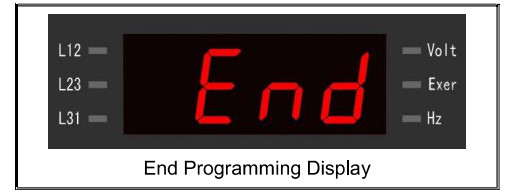

Remember to always press the “OFF” button to move to the next line or until the “End” appears on the screen.

Note : To end and exit at any time, hold the “OFF” button down for 4 seconds.

If you make an error or need to return to factory settings, stay or reenter programming and then hold the AUTO button down for 4 seconds, until the word “Apo” appears on the screen verifying that all programming lines are factory reset back like in the manual. (See line-by-line programming table for ATS-385 factory settings).

Remote Communication Instruction

You can monitor and control two gen-sets on a remote PC/Smartphone using the remote communication modules. Contact CBI for availability.

| Model | Communication interface |

| KCU-01 | USB |

| KCU-02 | RS-485 |

| KCU-30 | Ethernet (Dynamic IP) |

| KCU-40 | WI-FI |

| KCU-50 | 3G SIM Card |

WARNING

A remote start signal can start an engine via ATS-385 without warning. Place a “Danger” sign next to the generator stating it can start anytime! A warning buzzer / _ taillight’ installed’ is recommended. Unexpected engine starts can result in serious’ injury or death. When performing service or maintenance, always disconnect the remote start signal input.

When KCU-30, KCU-40, KCU-50 module is installed on ATS-385, it allows you to remote monitor or operate ATS and generator via iPhone or Android Mobil phones. Free App software currently available for Apple iOS5.‘ system or above and android operating system.

Download “Remote Communication’ free software by searching “Kutak” in Apple Store or Google Play.

The corresponding program settings for ATS-385 installed with KCU-XX module includes item (32), (33), (34) Programming item (32) is a must. When Item (32) is set to “00° Disable, then the remote monitoring software is restricted to read information only whereas remote command is strictly forbidden.

When KCU-02 — RS-485 communication module is installed, additional program setting on lines (33) and (34) are required.

Refer to KCU-XX hardware and software manual for detail information

WARNING

ATS-385 with KCU-02 module constitutes a closed LAN network. Each controller address can be setup range from 1 to 99 and not to be repeated. The transmission rate must be the same!

The installation for the KCU-XX communication module on the ATS-385 controller is fairly simple.

Step 1: Remove the slot cover from the back of controller. Step 2 : Insert KCU-XX module into the slot and tighten the screw.

Step 2 : Insert KCU-XX module into the slot and tighten the screw.

KCU Remote Connection Passwords Recovery

Step 1 : Make sure the KCU module is installed on the controller before carrying out remote connection passwords recovery.

Step 2 : Enter Program mode and set the program item (36) to (01) and press OFF button. 4-digit numbers “0000” and “9999” will appear on the display window about two seconds. Then “End” appears which means passwords have been restored successfully.

NOTICE

Program Line 36 is only available when KCU Module is installed on the ATS-385 controller.

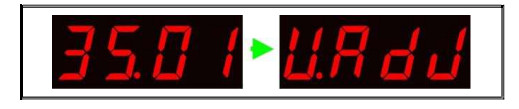

Voltage Adjustment

The ATS-385 voltage readings are factory set and calibrated. However, if you need to modify any voltage reading, follow these steps.

Step 1 : Ensure supply is connected to both the normal and standby line sides before undertaking Voltage calibration, and then manually start standby generator to generate power.

Step 2 : Enter Program mode and set the program item (35) to (01). “VAdJ” will appear on the display window. Step 3 : Select the phase you wish to re-calibrate by pressing the OFF button.

Step 3 : Select the phase you wish to re-calibrate by pressing the OFF button. Step 4 : Use a good quality voltmeter as a reference to calibrate the ATS-385 voltage reading to the desired phase.

Step 4 : Use a good quality voltmeter as a reference to calibrate the ATS-385 voltage reading to the desired phase.

Step 5 : With the up (▲) and down (▼) buttons reset the voltage reading on the ATS-385. Step 6 : Press the “OFF” button to move to the next phase or until the word “End” appears on the screen. To exit hold the “OFF” button at any time for 4 sec.

Step 6 : Press the “OFF” button to move to the next phase or until the word “End” appears on the screen. To exit hold the “OFF” button at any time for 4 sec. Step 7 : If you get “FAIL”, the calibration is null. Press the OFF button to reset and repeat Step 1.

Step 7 : If you get “FAIL”, the calibration is null. Press the OFF button to reset and repeat Step 1.

SECURITY NOTICE AND LIABILITY DISCLAIMER

You are responsible for keeping your KCU Remote Connection Passwords (Administrator/Viewer) safe and_ confidential because they are the key to access your equipment’s.

There will be potentially serious security issues if your passwords are compromised. Some of the risks of compromised security include the equipment being remotely controlled by third parties, who may have criminal intent and malicious damage to your equipment’s.

We are entitled to rely on any use of our connection services using that password as being use by you and authorized by you. If you know or believe that there is any unauthorized, fraudulent or unlawful use of your password, you must reset it in the controller. (Refer to controllers user manual for connection password reset)

Line By Line Programming Table

| Line | Description | Value | Factory Setting |

| 1 | Is this ATS operating in 1 Phase or 3 Phase? | 00 → 1 Phase 01 → 3 Phase | 01 |

| 2 | Select Switch ATS type See drawing on the back of this manual for guide on different ATS types | 00) MCCB BTS type ATS (Single motor) 1)Mot type (MCCB with separate motor) 2)Air circuit breaker type (ACB) 3)Double throw type (Without OFF position) 4)Double throw type (With OFF position) 5)Kutak TS-XXX type ATS 6)Magnetic contactor type ATS (MC) | 00 |

| 3 | TDEN Time Delay Emergency to Normal | 00 999 sec. | 10 sec. |

| 4 | TDNE Time Delay Normal to Emergency | 00 250 sec. | 10 sec. |

| 5 | TDES Time Delay Engine Start | 00 30 sec. | 5 sec. |

| 6 | TDEC Time Delay Engine Cool-down | 00 250 sec. | 30 sec. |

| 7 | Time Delay in the OFF Position | 00 99 sec. | 5 sec. |

| 8 | Normal over voltage protection setting | 39 49 ( 390 490V) | 44 (440V) |

| 9 | Normal under voltage protection setting | 30 41 ( 300 410V) | 36 (360V) |

| 10 | Time delay if there is a problem with the Normal voltage | 00 99 sec. ( 0 = Disable voltage monitoring ) | 10 sec. |

| 11 | Normal over frequency protection setting | 51 75 Hz | 55 Hz |

| 12 | Normal under frequency protection setting | 40 59 Hz | 45 Hz |

| 13 | Time delay if there is a problem with the Normal frequency | 00 99 sec. ( 0 = Disabled Hz monitoring ) | 10 sec. |

| 14 | Generator over voltage protection setting | 39 49 ( 390 490V) | 44 (440V) |

| 15 | Generator under voltage protection setting | 30 41 ( 300 410V) | 36 (360V) |

| 16 | Time delay if there is a problem with emergency voltage output | 00 99 sec. (0 = Function disabled) | 10 sec. |

| 17 | Generator over frequency setting | 51 75 Hz | 55 Hz |

| 18 | Generator under frequency setting | 40 59 Hz | 45 Hz |

| 19 | Time delay if there is a problem with the Generator frequency | 00 99 sec. (0 = Function disabled) | 10 sec. |

| 20 | Set today’s day of the week— Day | 1 7 ( Monday to Sunday ) | current |

| 21 | Set today’s hour — hour | 23 | Current |

| 22 | Set today’s minutes | 59 | current |

| 23 | Set day of week to do the engine exercise | 1 7 ( Monday to Sunday ) | 6 |

| 24 | Set the time to start the exercise | 00 23 ( 24 Hr Mode ) | 12 |

| 25 | Set generator automatic exercise cycle | 1)1 week 03) 3 weeks 2)2 weeks 04) 4 weeks | 1 |

| 26 | Exercising duration | 00 99 minutes ( 0 = Do not exercise ) | 0 |

| 27 | Exercise with load or without load | 00) Without load 01) With load | 0 |

| 28 | Test with load or without load | 00) Without load 01) With load | 1 |

| 29 | Display setting | 00) Cyclic Mode 01) Fix Mode | 0 |

| 30 | Program the auxiliary contact output | 00) Transfer failure 1)Pre-transfer 2)Pre-exerciser 3)When the ATS is in emergency position | 1 |

| 31 | Pre-transfer / Pre-exercising time delay before transfer load from one source to another source | 00 99 sec. | 10 |

| 32 | Remote control by KCU-XX module | 00 → Disable 01 → Enable | 0 |

| 33 | KCU-02 module address | 00 → KCU-02 module restricted 01 99 | 0 |

| 34 | KCU-02 module transmission rate | 01 → 115200 04 → 19200 07 → 4800 02 → 57600 05 → 14400 08 → 2400 03 → 38400 06 → 9600 09 → 1200 | 3 |

| 35 | Enter AC voltage correction | 00 → No 01 → Yes | 0 |

| 36 | Restore KCU Remote Connection Passwords to original factory default settings. (Administrator : 0000, Viewer : 9999) | 00 → No 01 → Yes | 0 |

Specification Summary

| Description | Specification |

| AC Voltage Input Range | 300 490 Vac 50/60 Hz |

| AC Voltage Display Range | 300 490 Vac 50/60 Hz |

| Frequency Measurement Range | 40 75 Hz |

| Remote Start Contact | 7A @ 250 Vac Max |

| Normal ON Contact | 5A @ 250 Vac Max |

| Emergency ON Contact | 5A @ 250 Vac Max |

| Auxiliary Contact Output | 7A @ 250 Vac Max |

| Operating Temperature | -20 to +70 C |

| Storage Temperature | -30 to +80 C |

| Relative Humidity | Max. 90% |

| Panel Cut-Out | 113.0 (L) x 168.0 (W) 4- 0.5 mm |

| Dimensions | 125.0 (L) x 180.0 (W) x 51.0 (H) mm |

| Weight | 890 g +/- 2% |

NOTICE

The control unit has no built-in protection fuses. Protection fuses should be installed when connection.

It is recommended to use the original factory equipment BUSSMANN S505H, 5Amps.

Failure to add a protective fuse or change to another brand or current value may result in damage to the control unit.

INSTALLATION INSTRUCTIONS

General

The ATS-385 is made for front panel mounting.

Figure / Size / Installation Reference ( All Dimensions in mm. )

CBI-Electric MCCB Type Transfer Switch wiring diagram

| PIN NO. | DESCRIPTION |

| CN1-1 | Normal power L1 voltage output |

| CN1-2 | Normal power L3 voltage output |

| CN1-3 | Normal Power L2 voltage output |

| CN1-4 | Emergency ON motor AC power input |

| CN1-5 | Normal ON signal output |

| CN1-6 | Normal ON motor AC power input |

| CN1-7 | Normal ON motor AC power input |

| CN1-8 | Emergency ON signal output |

| CN1-9 | Emergency ON motor AC power input |

| CN-10 | Emergency power L2 voltage output |

| CN1-11 | Emergency power L3 voltage output |

| CN1-12 | Emergency power L1 voltage output |

#NLS»Norrnal Auxiliary Switch

#ELS»Emergency Auxiliary Switch

12P AMP Housing

(Neutral Phase may be optional)

TYPICAL WIRING

Single motor MCCB Type ATS Wiring Diagram (3P/4P) — Called BTS Switch

MITSUBISHI MD Type ATS Wiring Diagram (3P/4P) — MCCB With Separate Motor

KUTAI TS-XXX Type ATS Wiring Diagram (3P)

Magnetic Contactor Type ATS Wiring Diagram (3P/4P)

APPENDIX : KCU Modules Connection Illustration

CBI-electric: low voltage

Trips itch Drive Elandsfontein

Gauteng South Africa

Tel: +27 I 1928 2000

Fax: + 27 I 1392 2354

Email: cbi@cbi-electric.com

Website: www.cbi-lowvoltage.co.za

Documents / Resources

| CBI CM-MI 125 Automatic Switch Control Unit [pdf] User Manual CM-MI 125 Automatic Switch Control Unit, CM-MI 125, Automatic Switch Control Unit, Switch Control Unit, Control Unit |