Danfoss AVQM-2 Flow Rate Controller With Motorized Valve

Product Specifications

- Type: AVQM-2

- Flow Rate: DN 32 – 50

- Language Options: English, Dansk, Deutsch, Polski

- Application: Flow rate controller with motorized valve

Product Usage Instructions

- Safety Notes: To avoid injury and damage, carefully read and follow the instructions. Only qualified personnel should perform assembly, startup, and maintenance. Depressurize the system before assembly.

- Definition of Application: The AVQM-2 controller is used with an electrical actuator for water and water-glycol mixtures in heating, district heating, and cooling systems. Refer to the technical data on the rating plates for proper use.

- Assembly:

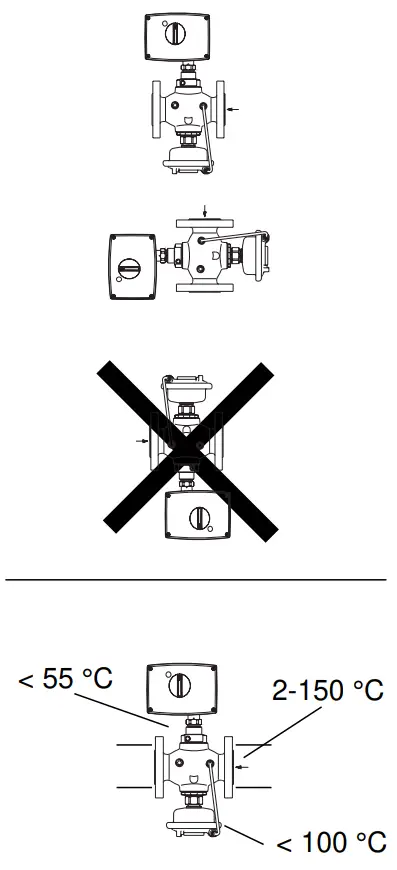

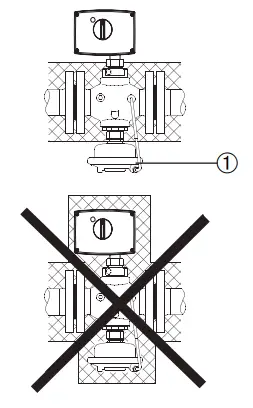

- Permissible Installation Positions: Ensure correct positioning during installation.

- Permissible Temperatures: Follow temperature guidelines for proper functioning.

- Installation Position and Scheme: Determine whether to install in the supply or return flow line. Refer to the installation diagram for guidance.

- Dimensions: Refer to the provided dimensions for accurate installation measurements.

- Pressure Test: Perform a pressure test after installation to ensure system integrity.

- Filling the System: Properly fill the system with the required fluid as per system specifications.

- Setting of Flowrate Restriction: Adjust the flow rate restriction according to system requirements for optimal performance.

- Troubleshooting: Refer to the troubleshooting section in case of any issues with the product.

- Minimum Pressure Difference: Maintain the minimum pressure difference as specified to avoid system malfunctions.

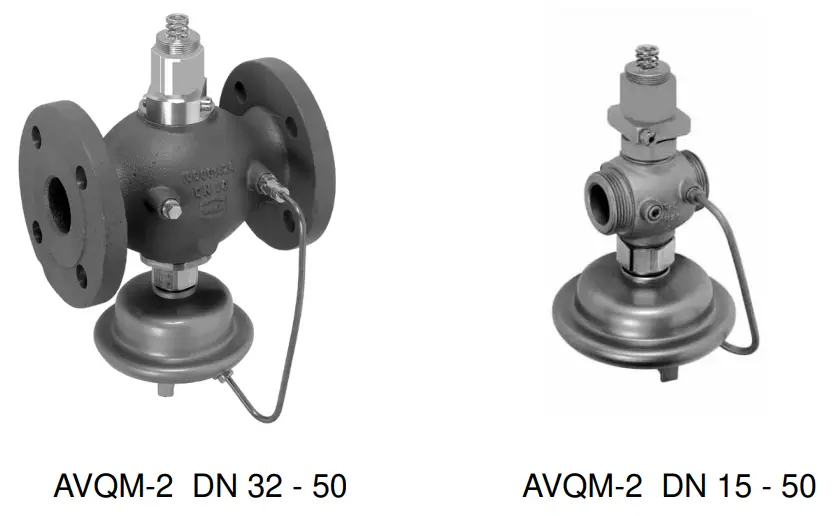

Models

- AVQM-2 DN 32 – 50

- AVQM-2 DN 15 – 50

Safety

Notes

- To avoid injury of persons and damages to the device, it is absolutely necessary to carefully read and observe these instructions.

- Necessary assembly, start-up, and maintenance work may be performed only by qualified and authorized personnel.

- Prior to assembly and disassembly, depressurized system!

- Please comply with the instructions of the system manufacturer or system operator.

Definition of Application

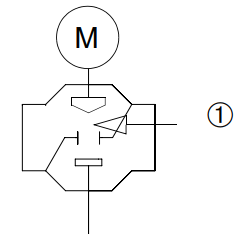

- In combination with an electrical actuator (AME, AMV 2., 3.), the controller AVQM-2 is used of water, water glycol mixtures for heating, district heating and cooling systems.

- The technical data on the rating plates determine the use.

Assembly

- Permissible Installation

- Positions

- Permissible

- Temperatures

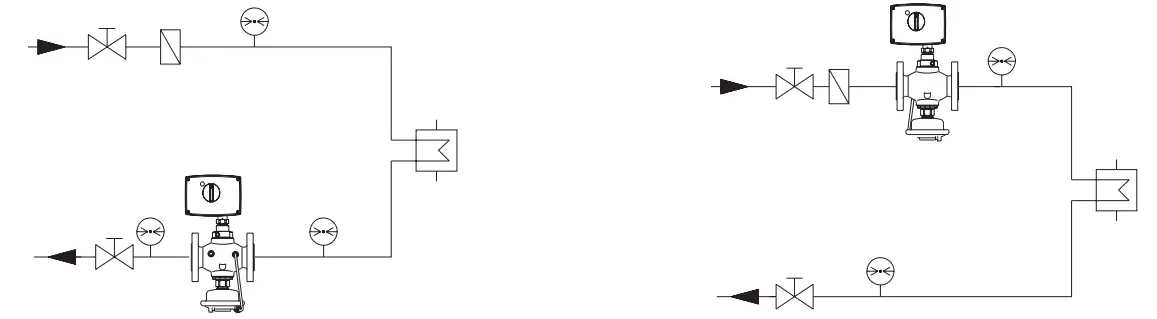

- Installation Position and Scheme

- Supply or return flow

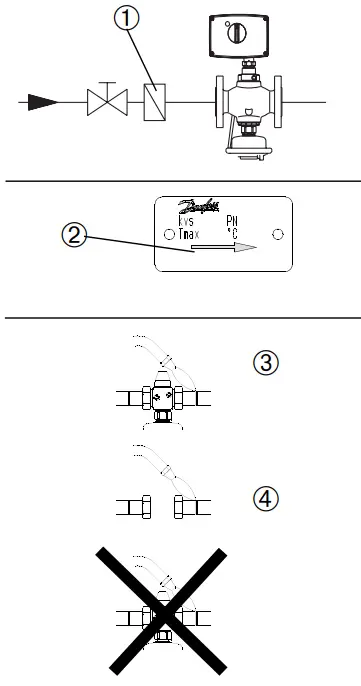

Installation

- Install strainer

- before controller.

- Observe flow direction

- on rating plate. Design with welded end

- pin only

- weld

- Rinse system.

- If necessary, carry out pressure tests, see section “Pressure Tests“.

- Set the flow rate limitation, see page 8.

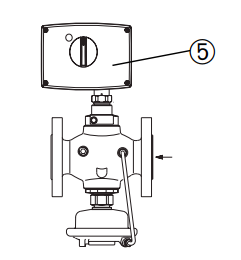

- Then, mount electrical actuator ➄.

Keep to the Assembly Instructions for the respective actuator, „Assembly“ section.

Insulation

Pressure actuator ➀ can be insulated up to a medium temperature of 100 °C.

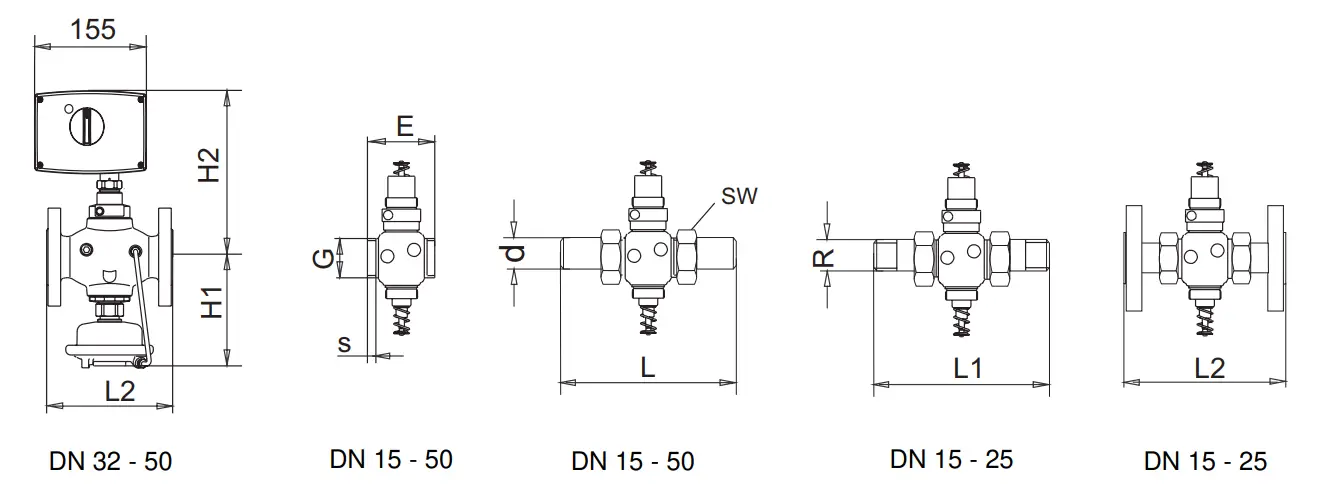

Dimensions

- Conic male thread acc. to DIN 2999

- Flanges PN 25:

Connection dimensions acc. to DIN 2501, seal form C

| DN | 15 | 20 | 25 | 32 | 40 | 50 | |

| R 1) | R1/2 | R3/4 | R 1 | ||||

| G ISO 228/1 | G3/4A | G1A | G11/4A | G13/4A | G2A | G21/2A | |

| s |

mm | 8,5 | 10 | 11 | 13,5 | 15,5 | 17,5 |

| SW | 32 | 41 | 50 | 63 | 70 | 82 | |

| d | 21 | 26 | 33 | 42 | 48 | 60 | |

| E | 65 | 70 | 75 | 100 | 110 | 130 | |

| L | 139 | 154 | 159 | 184 | 204 | 234 | |

| L1 | 125 | 146 | 169 | ||||

| L2 2) | 130 | 150 | 160 | 180 | 200 | 230 | |

| H1 | 119 | 125 | 125 | 155 | 159 | 159 | |

| H2 | 201 | 208 | 208 | 220 | 220 | 220 | |

Pressure Tests

- Do not test closed valves with pressures of more than 16 bar.

- Otherwise, the valve may be damaged.

- Pressure tests should be carried out prior to the installation of the actuator.

- This guarantees that the valve is opened.

Handling: Slowly increase pressure.

Filling the System

Take care that the valve is OPEN.

Setting of Flow Rate Restriction

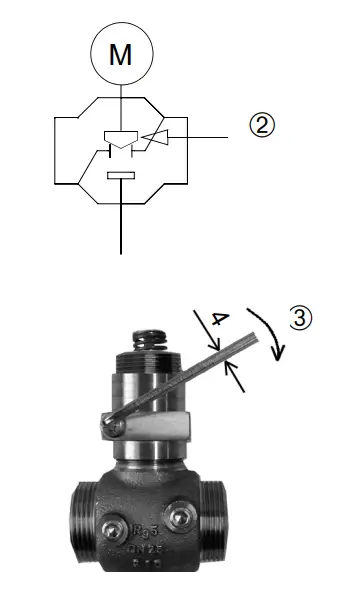

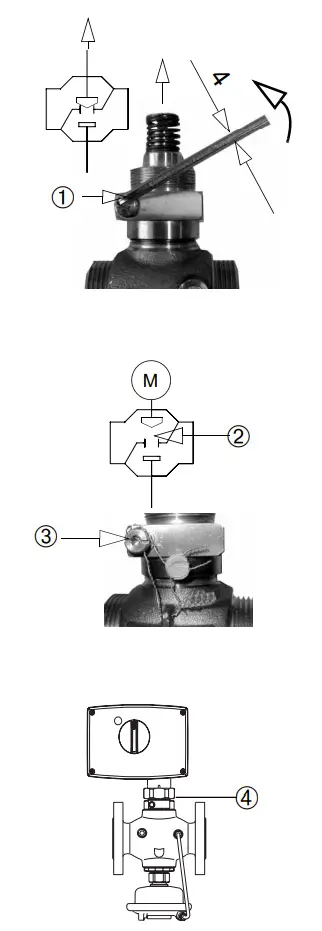

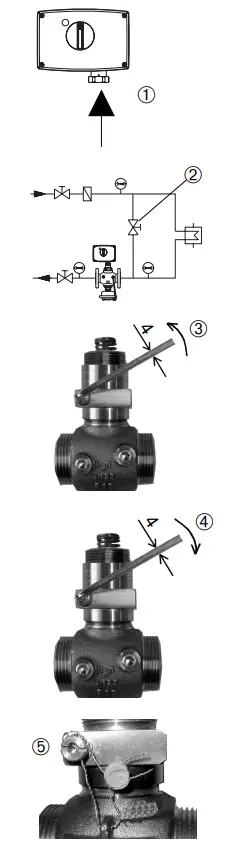

The adjustment of the flow is carried out by limiting the valve stroke ➀.

There are two possibilities:

- Adjustment with adjusting curves.

- Adjustment with heat meter, see page 11.

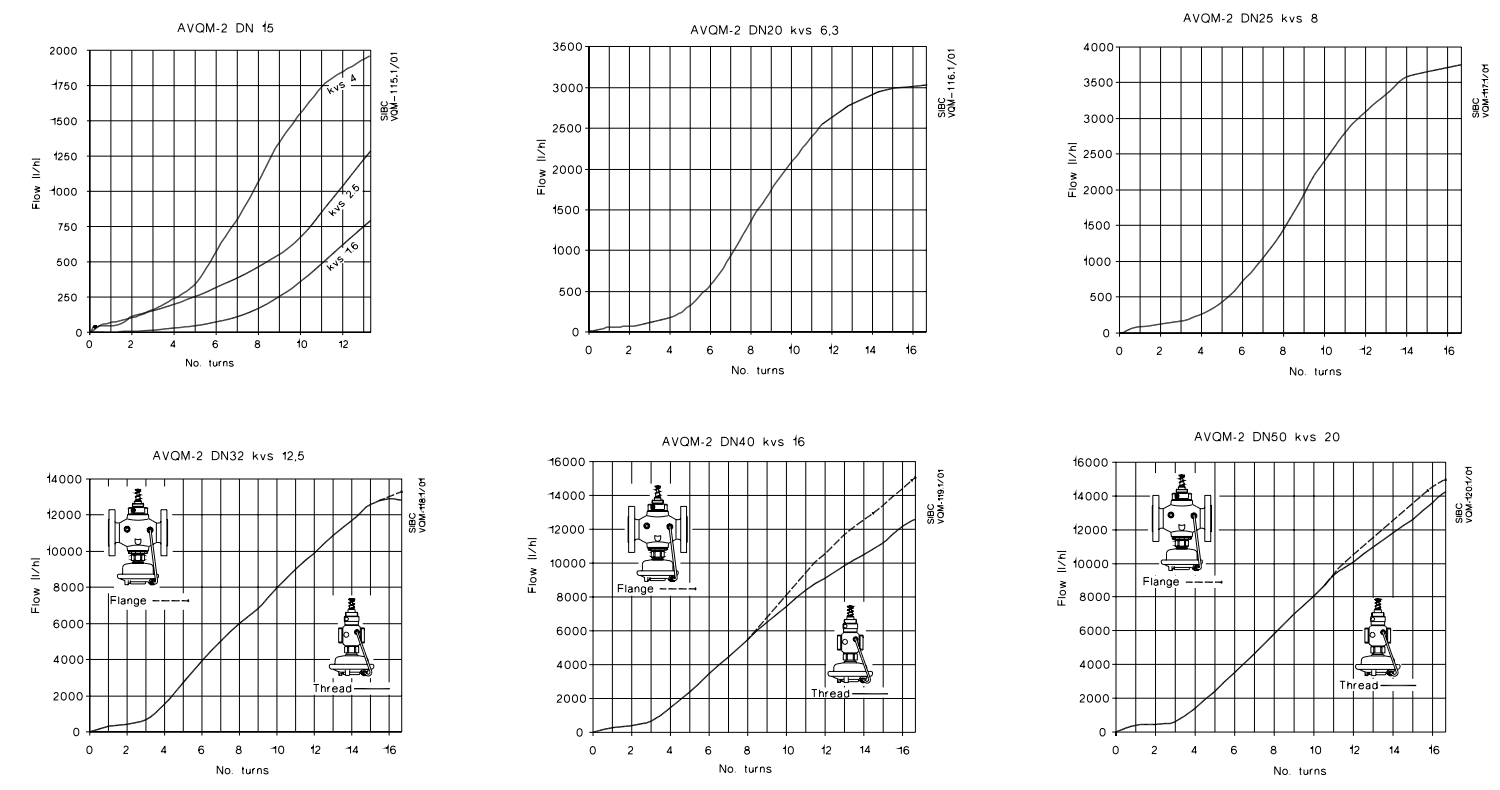

Adjustment with adjusting curves

The system need not be active for being adjusted!

- Close valve ➁ by turning the adjusting screw ➂ to its stop.

- Select adjusting curve

- Turn adjusting screw ➀ by this number of rotations counter-clockwise. ➻Setting of the valve stroke ➁ is completed.

- The adjusting screw ➂ may be sealed.

- If not yet done, install the actuator ➃, see Assembly Instructions for the respective actuator, “Assembly” section.

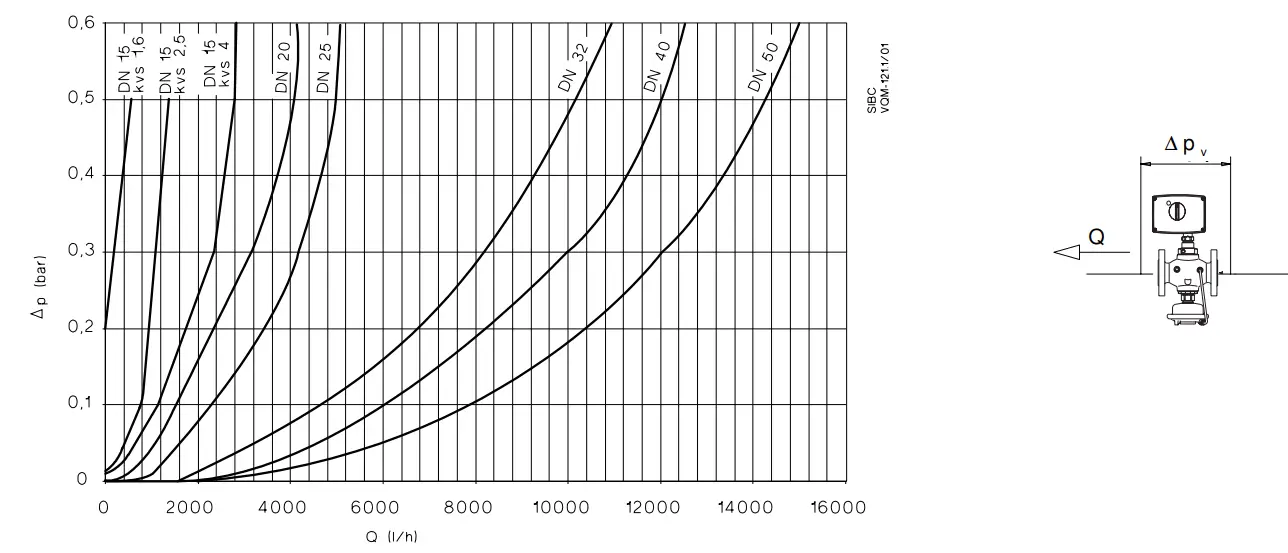

Adjusting Curves

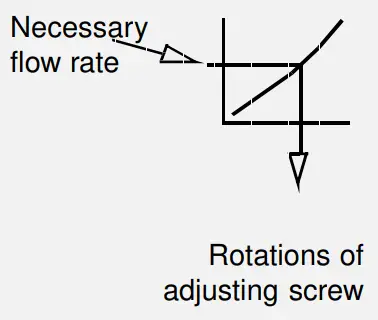

Adjustmen with Heat Meter

- The setting should be carried out when the actuator AMV.. is dismounted. If the actuator is mounted, the stem of the actuator must be retracted.

- Take care that system or bypass ➁ is completely opened.

- Observe heat meter. Turning counterclockwise ➂ increases the flow. Turning clockwise ➃ reduces the flow.

- When the heat meter shows the required value, shortly throttle the system and then re-open it (e.g. by means of the electrical actuator).

- Verify flow rate. The valve setting is completed.

- The adjusting screw ➄ may be sealed.

Troubleshooting

| Troubleshooting | ||

| Fault | Possible cause | Remedy |

| Flow rate not reached. | Presssure difference with regard to valve too low. | Verify pressure difference, minimum pressure difference required see next section. |

| Wrong setting of flow rate restriction. | Verify setting, see section „Setting of Flow Rate Restriction“. | |

| Valve is dirty. | Uninstall valve, clean or replace it if necessary. | |

| Flow rate is limited by electrical actuator. | Check electrical actuator. | |

| Flow rate too high. |

Control line is dirty. |

Dismount control line, check control line and connections for free passage, clean if necessary. |

| Pressure actuator is defect e.g. diaphragm leaky. | Dismount and check actuator, an replace it if diaphragm is leaky. | |

| Wrong setting of flow rate restriction. | Verify setting, see section „Setting of Flow Rate Restriction“. | |

Minimum Pressure Difference

Minimum pressure difference required from the control valve

FAQ

Q: Can I install the AVQM-2 controller myself?

A: Assembly and installation should only be done by qualified personnel to ensure safety and proper function of the device.

Q: What should I do if I encounter a problem with flow rate adjustment?

A: Refer to the troubleshooting section in the manual for guidance on resolving flow rate adjustment issues.

Documents / Resources

| Danfoss AVQM-2 Flow Rate Controller With Motorized Valve [pdf] User Guide AVQM-2 Flow Rate Controller With Motorized Valve, AVQM-2, Flow Rate Controller With Motorized Valve, With Motorized Valve, Motorized Valve, Valve |