1. Introduction

This manual provides essential information for the safe and effective installation, operation, and maintenance of the Phicus MS-02 Motor Driver Board. This board is a critical spare part designed for use within China Dahao embroidery machine systems, facilitating precise motor control for optimal machine performance.

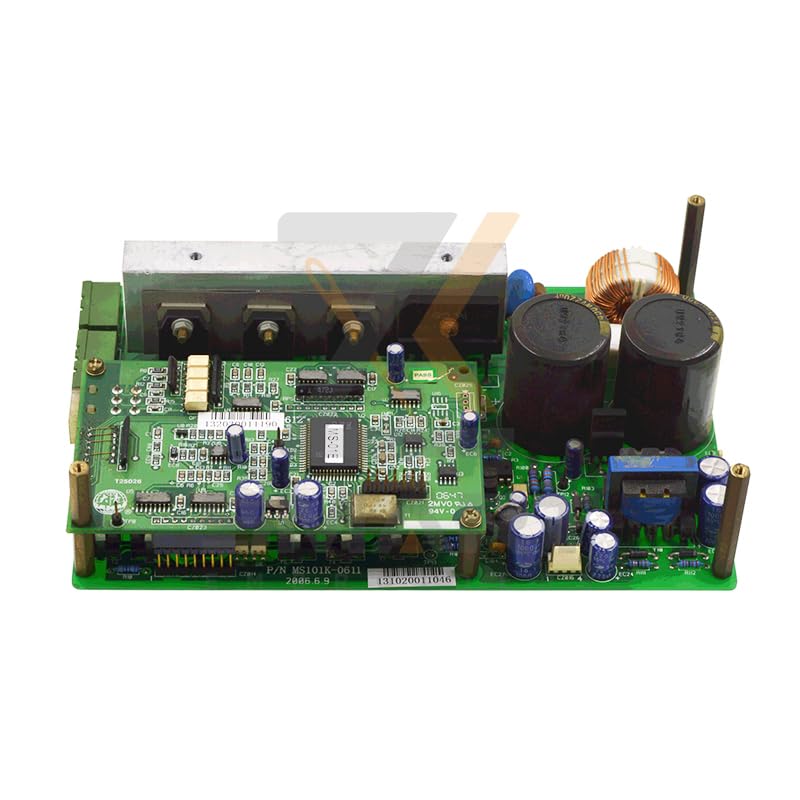

Figure 1: Phicus MS-02 Motor Driver Board. This image displays the compact electronic board with various connectors and components, typical of a motor driver for industrial embroidery machines.

2. Setup and Installation

2.1 Safety Precautions

- Always disconnect power to the embroidery machine before attempting any installation or maintenance.

- Wear appropriate personal protective equipment (PPE), such as anti-static gloves, to prevent electrostatic discharge (ESD) damage to sensitive electronic components.

- Ensure the work area is clean, dry, and well-lit.

- If you are unfamiliar with electronic component installation, seek assistance from a qualified technician.

2.2 Installation Steps

- Power Disconnection: Turn off the main power switch of the Dahao embroidery machine and unplug it from the power source.

- Access Panel Removal: Locate and carefully remove the access panel(s) that cover the existing motor driver board within the machine's control cabinet.

- Old Board Removal: Disconnect all cables from the old motor driver board, noting their positions and orientations. Use a camera to take pictures if necessary. Carefully unmount the old board from its housing.

- New Board Installation: Gently place the Phicus MS-02 Motor Driver Board into the designated slot. Ensure it is properly aligned with mounting points.

- Secure the Board: Fasten the new board using the appropriate screws or clips, ensuring it is securely mounted and does not wobble.

- Cable Connection: Reconnect all cables to the new MS-02 board, matching them to their original positions. Double-check all connections for tightness and correct orientation.

- Panel Reinstallation: Replace the access panel(s) and secure them.

- Power Restoration: Plug the embroidery machine back into the power source and turn on the main power switch.

3. Operation

The Phicus MS-02 Motor Driver Board operates as an integral component of the Dahao embroidery machine's control system. Once correctly installed, it receives commands from the machine's main controller to precisely manage the speed, direction, and position of the embroidery motors (e.g., X/Y axis motors, needle bar motors). No direct user interaction with the board itself is typically required during normal operation.

3.1 Basic Functionality

- Motor Control: Translates digital signals from the machine's CPU into electrical currents to drive stepper or servo motors.

- Positioning Accuracy: Ensures motors move to precise positions, critical for accurate embroidery patterns.

- Speed Regulation: Controls the rotational speed of motors according to programmed parameters.

- Error Detection: May include basic fault detection capabilities to protect motors and the board from overcurrent or overheating.

4. Maintenance

Proper maintenance extends the lifespan of the motor driver board and ensures consistent machine performance. Always disconnect power before performing any maintenance.

- Dust Removal: Periodically (e.g., every 3-6 months, depending on environment) use compressed air to gently remove dust and debris from the board's surface and cooling fins (if present). Ensure the air is dry and oil-free.

- Visual Inspection: Regularly inspect the board for any signs of damage, such as burnt components, loose connections, or corrosion.

- Connection Check: Ensure all cable connections remain secure and free from oxidation.

- Environmental Control: Operate the embroidery machine in a clean, temperature-controlled environment to prevent excessive heat buildup and contamination.

5. Troubleshooting

This section outlines common issues that may indicate a problem with the motor driver board and potential solutions. Always ensure the machine's power is off before inspecting internal components.

| Problem | Possible Cause | Solution |

|---|---|---|

| Motor not moving or erratic movement | Loose cable connection; Faulty motor; Damaged driver board; Incorrect settings in machine controller. | Check all motor and power connections. Test the motor if possible. Consult machine's main manual for controller settings. If other solutions fail, the driver board may need replacement. |

| Overheating of the board | Insufficient ventilation; Excessive motor load; Faulty board component. | Ensure proper airflow around the board. Reduce motor load if possible. Inspect for dust buildup. If overheating persists, the board may be faulty. |

| Machine displays motor error code | Communication error; Motor fault; Driver board fault. | Refer to the Dahao embroidery machine's main error code manual. Check cable integrity. If the error points to a driver issue, consider board replacement. |

| No power to the board | Loose power connection; Blown fuse (if applicable); Power supply unit (PSU) fault. | Verify power connections. Check for any fuses on the board or in the machine's power supply. Test the PSU output. |

6. Specifications

Technical specifications for the Phicus MS-02 Motor Driver Board (Model: PHC-C0CD5298EDE4DFCF6F31E2CEB092CF24).

| Feature | Detail |

|---|---|

| Manufacturer | Generic |

| Part Number | PHC-C0CD5298EDE4DFCF6F31E2CEB092CF24 |

| Model Compatibility | China Dahao Embroidery Machine Systems |

| ASIN | B0D4LSV4VP |

| Date First Available | Sept. 11 2023 |

| Included Components | x (Not specified beyond the board itself) |

| Measurement Accuracy | x (Not specified) |

7. Warranty and Support

For specific warranty information regarding the Phicus MS-02 Motor Driver Board, please refer to the purchase documentation or contact the seller directly. As a spare part, warranty terms may vary. For technical support or further inquiries, please reach out to the original equipment manufacturer (Dahao) or the supplier from whom the board was purchased.