Introduction

The Mainline #4963 Full-Port Backwater Valve is designed to prevent sewage backup into homes or buildings, particularly those with basements, cellars, crawl spaces, or other areas accessible for servicing. This valve features a normally open gate, which allows the sewer system to vent gases and ensures unrestricted flow under normal conditions. The 'Clear View' top facilitates quick and simple inspection by the building owner or plumber. Additionally, the #4963 includes an integral clean-out, allowing for easy rodding of the sewer lateral. The design permits a snake to pass over the open gate without damaging internal components if rodding from the stack is necessary.

Image: Mainline 4-inch ABS Backwater Valve, showing its overall design and clear top.

Product Features

- Full-Port, Normally-Open Design: Ensures unrestricted flow and allows sewer gases to vent under normal conditions.

- Unique Patented Design: Engineered to minimize failure points and facilitate easy cleaning and rodding.

- Clear View Top: Provides convenient visual inspection of the valve's internal components and operation.

- Integral Clean-Out: Allows for direct access to the sewer lateral for rodding without disassembling the valve.

- Durable ABS Construction: Made from Acrylonitrile Butadiene Styrene for longevity and resistance to corrosion.

Safety Information

Always adhere to local plumbing codes and regulations during installation and maintenance. Professional installation is recommended. Wear appropriate personal protective equipment (PPE), including gloves and eye protection, when handling plumbing materials and working with sewer lines. Ensure adequate ventilation in work areas. If working with existing plumbing, confirm that water supply and any relevant utilities are safely shut off before beginning work.

Installation and Setup

The Mainline ABS Backwater Valve is designed for installation in 4-inch DWV (Drain, Waste, Vent) ABS piping systems. It features solvent-weld hubs on both ends for secure connection. Ensure the valve is installed with the flow arrow pointing away from the building's fixtures and towards the municipal sewer line. Proper alignment and secure solvent welding are critical for leak-free operation.

Image: Operational diagram illustrating normal flow (top) and how the flap blocks backflow from the sewer (bottom).

The valve should be installed in an accessible location, such as a basement, cellar, or crawl space, to allow for future inspection and maintenance. Ensure sufficient space around the valve for proper installation and access to the clean-out port.

Operation

Under normal conditions, the valve's gate remains open, allowing wastewater to flow freely from the home to the sewer and permitting sewer gases to vent. This full-port design ensures no restriction to normal drainage. In the event of back pressure or backflow from the municipal sewer system, the internal flap automatically floats up and closes, sealing the pipe and preventing sewage from entering the building's plumbing system. Once the back pressure subsides, the flap returns to its open position, restoring normal flow.

Maintenance

Regular inspection of the backwater valve is crucial to ensure proper function. The 'Clear View' top allows for visual inspection of the internal flap and chamber for any debris accumulation. Periodically, remove the clear top and inspect the flap for any obstructions or damage. Clean any debris that may hinder the flap's movement. The integral clean-out port can be used for rodding the sewer lateral if blockages occur downstream of the valve. When rodding, ensure the snake passes over the open gate to avoid damage to the valve components.

Image: Cutaway view of the Mainline backwater valve, highlighting the internal gate and flow channels.

Troubleshooting

- Valve Not Closing: If the valve fails to close during a backflow event, inspect the clear top for any visible debris obstructing the flap. Ensure the flap mechanism is correctly seated and not dislodged.

- Slow Drainage: While the full-port design minimizes restriction, excessive debris accumulation within the valve or further down the sewer line can impede flow. Use the clean-out port for rodding if necessary.

- Leakage: Check all solvent-welded connections for proper sealing. If leakage occurs from the valve body itself, inspect for cracks or damage.

- Persistent Backflow: If backflow continues despite the valve closing, it may indicate an issue with the valve's seal or a severe blockage that is overwhelming the system. Professional plumbing assistance is recommended.

Specifications

| Model Number | ML-4963A |

| Material | Acrylonitrile Butadiene Styrene (ABS) |

| Item Dimensions (L x W x H) | 18 x 14 x 14 inches |

| Item Weight | 5.97 pounds |

| Inlet Connection Size | 4 Inches |

| Outlet Connection Size | 4 Inches |

| Inlet Connection Type | Full Port |

| Number of Ports | 2 |

| Installation Method | Glue (Solvent Weld) |

| UPC | 696794000014 |

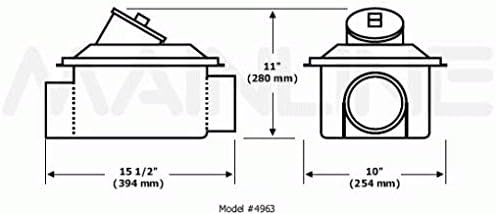

Image: Dimensional drawing of the Mainline Model #4963 backwater valve, showing key measurements.

Warranty and Support

Specific warranty details for the Mainline 4-inch ABS Backwater Valve ML-4963A are not provided in this document. For warranty information, technical support, or service inquiries, please contact Mainline Backflow Products Inc. directly or refer to the official product packaging and documentation. It is recommended to retain your purchase receipt for warranty claims.