1. Introduction

This manual provides essential information for the safe and efficient installation, operation, and maintenance of your Wayne CDU980E 3/4 HP Submersible Sump Pump. Please read all instructions carefully before use and retain this manual for future reference.

Figure 1: Wayne CDU980E 3/4 HP Submersible Sump Pump

2. Safety Information

WARNING: Risk of electric shock. This pump is supplied with a grounding conductor and grounding-type attachment plug. To reduce the risk of electric shock, be certain that it is connected only to a properly grounded grounding-type receptacle.

- Always disconnect power to the pump before handling or servicing.

- Do not operate the pump in an explosive atmosphere.

- Ensure the electrical circuit is protected by a Ground Fault Circuit Interrupter (GFCI).

- Do not use this pump for pumping flammable or corrosive liquids.

- Keep hands clear of the pump intake and discharge openings when the pump is connected to power.

- This pump is designed for indoor use only in sump pits.

3. Package Contents

Verify that all components are present and undamaged:

- Wayne CDU980E Sump Pump with Integrated Vertical Float Switch

- Instruction Manual

4. Key Features

- 3/4 HP Motor: Capable of moving up to 5,490 gallons per hour (GPH).

- Durable Construction: Features corrosion-resistant stainless steel motor housing and fasteners with a cast-iron volute for extended life.

- Integrated Vertical Float Switch: Designed for reliable automatic operation, tested to 1 million cycles.

- Top Suction Design: Helps prevent air lock and minimizes clogging from debris at the bottom of the sump pit.

- 1-1/2 inch NPT Discharge: Standard size for compatibility with common plumbing codes.

- Easy Installation: Designed for quick setup, typically within 15 minutes, without the need to drill a weep hole.

Figure 2: Key Features of the Wayne CDU980E

5. Setup and Installation

The Wayne CDU980E sump pump is designed for installation in 11-inch diameter or larger sump pits. Follow these steps for proper installation:

- Prepare the Sump Pit: Ensure the sump pit is clean and free of debris. The pump should sit on a solid, level surface.

- Connect Discharge Pipe: Thread a 1-1/2 inch NPT discharge pipe into the pump's outlet. Use appropriate sealant for a watertight connection.

- Install Check Valve: Install a check valve in the discharge line above the pump to prevent water from flowing back into the sump pit when the pump shuts off.

- Position the Pump: Carefully lower the pump into the sump pit. Ensure the float switch can move freely without obstruction from the pit walls or other pipes.

- Electrical Connection: Plug the pump into a properly grounded 120V, 60Hz electrical outlet protected by a GFCI. Ensure the power cord is routed to prevent damage.

- Test Operation: Pour water into the sump pit to verify the float switch activates the pump and discharges water correctly.

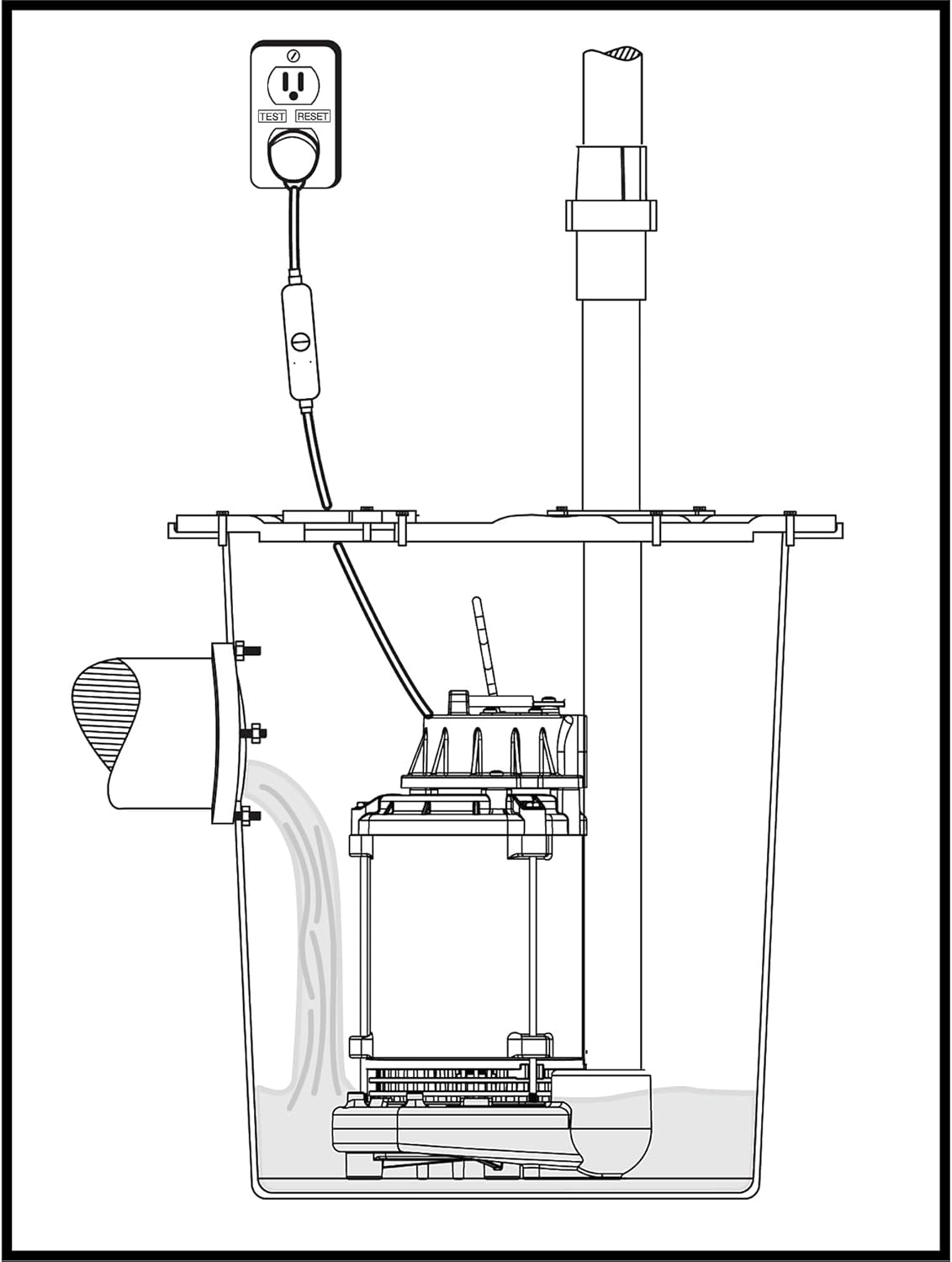

Figure 3: Typical Sump Pump Installation

Installation Overview Video

Video 1: An overview of a similar Wayne sump pump, demonstrating its features and installation considerations. This video is provided by the manufacturer.

6. Operating Instructions

The Wayne CDU980E operates automatically via its integrated vertical float switch. When water in the sump pit rises and lifts the float to the 'ON' level (approximately 9 inches), the pump will activate and begin discharging water. Once the water level drops and the float returns to the 'OFF' level (approximately 4 inches), the pump will shut off. This automatic operation ensures your basement remains dry without constant manual intervention.

Figure 4: Wayne CDU980E Sump Pump Label

7. Maintenance

Regular maintenance helps ensure the longevity and reliable operation of your sump pump:

- Inspect Regularly: Periodically check the sump pit for debris that could obstruct the float switch or pump intake.

- Clean Intake Screen: Ensure the pump's intake screen is clear of leaves, dirt, or other foreign objects.

- Test Float Switch: Manually lift the float switch to ensure the pump activates and deactivates correctly. This should be done monthly, especially during rainy seasons.

- Check Discharge Line: Verify that the discharge pipe is not clogged or frozen, especially in colder climates.

- Power Cord Inspection: Check the power cord for any signs of damage or wear.

8. Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Pump does not run | No power; tripped GFCI; stuck float switch; motor failure. | Check power supply and GFCI. Clear float switch. Consult a qualified technician for motor issues. |

| Pump runs continuously | Stuck float switch; check valve failure; continuous water inflow. | Clear float switch. Inspect/replace check valve. Address source of continuous water. |

| Pump runs but no water discharges | Clogged intake or discharge pipe; air lock; low water level. | Clear obstructions. Ensure pump is fully submerged. Check for weep hole (not needed for this model, but common issue). |

| Pump is noisy or vibrates excessively | Debris in impeller; pump not stable; worn bearings. | Disconnect power and inspect impeller for debris. Ensure pump is on a stable surface. Contact support for internal issues. |

9. Specifications

Figure 5: Wayne CDU980E Product Dimensions

| Attribute | Value |

|---|---|

| Brand | Wayne |

| Model Number | CDU980E (58321-WYN3) |

| Horsepower | 0.75 HP |

| Maximum Flow Rate | 5490 GPH (92 Gallons Per Minute) |

| Maximum Lifting Height | 32 Feet |

| Voltage | 120 Volts |

| Power Source | Corded Electric |

| Material | Cast Iron and Stainless Steel |

| Product Dimensions | 10.5"L x 9"W x 11"H |

| Item Weight | 12 Pounds |

| Special Features | Integrated Vertical Float Switch, Easy to Install |

Figure 6: Performance Data for CDU980E

10. Warranty and Support

The Wayne CDU980E Submersible Sump Pump comes with a 5 Year Manufacturer's Warranty. For warranty claims, technical assistance, or replacement parts, please contact Wayne Water Systems customer support. Refer to the contact information provided in your product packaging or visit the official Wayne website.

Manufacturer: Wayne Water Systems