1. Introduction

The Laser 3568 Alldrive Socket & Bit Set is a comprehensive 40-piece miniature tool kit designed for a wide range of fastening applications. This set features Alldrive profile sockets, capable of fitting various fastener types, along with a selection of impact-grade bits and essential accessories. Manufactured with quality materials like polished chrome vanadium for sockets and S2 impact-grade steel for bits, this set provides versatility and durability for professional and DIY use.

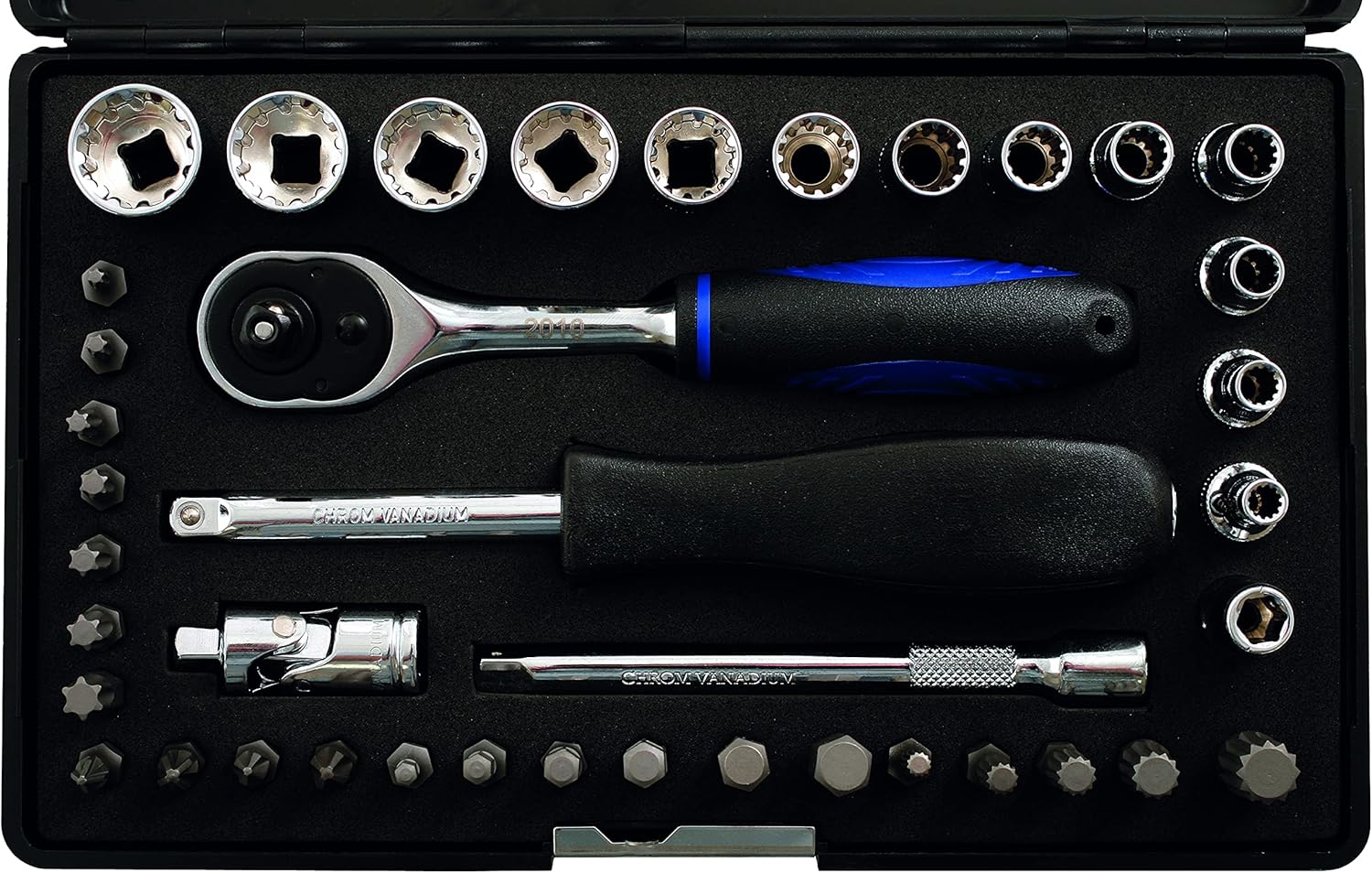

Figure 1: The Laser 3568 Alldrive Socket & Bit Set, 40-piece, presented in its durable storage case.

2. Product Components

This 40-piece set includes a variety of sockets, bits, and accessories designed for maximum utility. The Alldrive sockets are engineered to fit multiple fastener profiles, enhancing the set's versatility.

2.1. Alldrive Sockets (13 pieces)

- 4mm Socket

- 4.5mm Socket

- 5mm Socket

- 5.5mm Socket

- 6mm Socket

- 7mm Socket

- 8mm Socket

- 9mm Socket

- 10mm Socket

- 11mm Socket

- 12mm Socket

- 13mm Socket

- 14mm Socket

2.2. 30mm Bit Set (21 pieces)

- Phillips: Ph1, Ph2

- PzDrive: Pz2

- Hex: 3, 4, 5, 6, 7, 8 mm

- Star*: T10, T15, T20, T25, T27, T30, T40

- Spline: M4, M5, M6, M8, M10

2.3. Accessories (5 pieces)

- 72 teeth ratchet

- Universal joint

- Extension bar (100 mm long)

- 100 mm bit adaptor

- Spinner handle

Figure 2: Detailed view of the sockets, bits, and accessories within the set's foam insert.

2.4. Alldrive Socket Compatibility Chart

The Alldrive sockets are designed to fit a variety of fastener profiles. Refer to the table below for common compatibilities:

| Alldrive (M) | Star (F) | Star (Spline) | AF | Whitworth | BSF | BA | |

|---|---|---|---|---|---|---|---|

| 4mm | T25 | E5 | M5 | 5/32" | |||

| 4.5mm | T27 | E6 | |||||

| 5mm | T30 | E7 | M6 | 3/16" | |||

| 5.5mm | T35 | ||||||

| 6mm | T40 | E8 | M8 | 9/32" | |||

| 7mm | T47 | E11 | |||||

| 8mm | M10 | 5/16" | 1/8" | 3/16" | 3BA | ||

| 9mm | 2BA | ||||||

| 10mm | M12 | 3/8" | |||||

| 11mm | T60 | E16 | M14 | ||||

| 12mm | T70 | E18 | 7/16" | 3/16" | 1/4" | ||

| 13mm | 1/2" | 1/4" | 5/16" | ||||

| 14mm |

*STAR is equivalent to TORX® & SIDED TORX® is the registered trademark of CAMCAR TEXTRON INC. ROCKFORD IL

3. Setup

Before using the Laser 3568 Alldrive Socket & Bit Set, ensure you have identified the correct socket or bit for your application. Proper selection prevents damage to both the fastener and the tool.

- Identify Fastener Type: Determine the type of fastener you are working with (e.g., Hex, Torx, Spline, Phillips, Pozidriv, Metric, AF, Whitworth, BA, BSF).

- Select Correct Socket/Bit: Choose the Alldrive socket or bit that matches the fastener size and type. Refer to the compatibility chart in Section 2.4 if unsure.

- Attach to Ratchet or Handle:

- For sockets: Firmly push the selected socket onto the square drive of the 72 teeth ratchet or the universal joint. Ensure it clicks securely into place.

- For bits: Insert the desired bit into the 100 mm bit adaptor. Then, attach the bit adaptor to the square drive of the ratchet or spinner handle.

- Utilize Accessories:

- Use the 100 mm extension bar for reaching fasteners in confined spaces. Attach it between the ratchet/spinner handle and the socket/bit adaptor.

- The universal joint allows for angled access to fasteners. Attach it between the ratchet/extension and the socket.

- The spinner handle is ideal for quick, low-torque fastening or loosening once a fastener is broken free.

4. Operating Instructions

Using the Laser 3568 Alldrive Socket & Bit Set effectively requires proper technique to ensure safety and prevent damage to tools or fasteners.

- Secure the Fastener: Place the selected socket or bit firmly onto the head of the fastener, ensuring a snug fit. Avoid using ill-fitting tools, as this can strip the fastener head.

- Ratchet Direction: For the 72 teeth ratchet, locate the directional switch on the head. Flip the switch to the desired direction for tightening (clockwise) or loosening (counter-clockwise).

- Apply Force: Apply steady, even pressure to the handle of the ratchet or spinner handle. For stubborn fasteners, apply gradual, increasing force. Avoid sudden jerking motions.

- Tightening: Turn the ratchet clockwise until the fastener is adequately tightened. Do not overtighten, as this can damage the fastener or the material it's secured to.

- Loosening: Turn the ratchet counter-clockwise to loosen the fastener. Once the fastener is loose, the spinner handle can be used for faster removal.

- Bit Usage: When using bits, ensure the bit is fully seated in the fastener head to prevent cam-out and damage.

Important: Always wear appropriate personal protective equipment, such as safety glasses, when using hand tools.

5. Maintenance

Proper maintenance extends the life and performance of your Laser 3568 Alldrive Socket & Bit Set.

- Cleaning: After each use, wipe down all components with a clean, dry cloth to remove dirt, grease, and debris. For stubborn grime, a mild degreaser can be used, followed by thorough drying.

- Lubrication (Ratchet): Periodically, apply a small amount of light machine oil to the internal mechanism of the ratchet head. This helps maintain smooth operation and prevents corrosion. Avoid over-lubricating.

- Inspection: Regularly inspect sockets, bits, and accessories for signs of wear, cracks, or damage. Replace any damaged components immediately to ensure safe and effective operation. Pay close attention to the drive ends of sockets and the tips of bits.

- Storage: Always store the set in its original durable case. This protects the tools from moisture, dust, and physical damage, and keeps them organized. Store in a dry environment to prevent rust.

- Material Care: The sockets are manufactured from polished chrome vanadium, and the bits from S2 impact-grade steel. These materials are designed for durability, but proper care is still essential. Avoid exposing tools to corrosive chemicals.

6. Troubleshooting

This section addresses common issues that may arise during the use of your socket and bit set.

| Problem | Possible Cause | Solution |

|---|---|---|

| Socket/Bit slips on fastener | Incorrect size or type of tool; Worn fastener head; Worn socket/bit. | Ensure correct size and type are selected. Replace worn fastener if possible. Inspect and replace worn socket/bit. |

| Ratchet mechanism sticks or slips | Lack of lubrication; Dirt/debris in mechanism; Internal wear/damage. | Apply light machine oil to the ratchet head. Clean out any visible debris. If problem persists, the ratchet may require professional repair or replacement. |

| Socket/Bit difficult to attach/detach | Dirt/corrosion on drive square; Bent drive square; Debris in socket/bit. | Clean drive squares and socket/bit interiors. Ensure components are aligned correctly. If bent, replace the affected component. |

| Tool shows signs of rust | Exposure to moisture; Improper storage. | Clean off rust with a rust remover or fine abrasive. Apply a light coat of oil. Store in a dry environment and ensure tools are clean before storage. |

7. Specifications

Key technical specifications for the Laser 3568 Alldrive Socket & Bit Set:

| Attribute | Detail |

|---|---|

| Brand | Laser |

| Model Number | 3568 |

| Number of Pieces | 40 |

| Material | S2 Steel, Alloy Steel, Chrome Vanadium Steel |

| Finish Type | Polished |

| Item Weight | 1.1 pounds (approx. 0.5 kg) |

| Product Dimensions | 1.46 x 5.04 x 8.03 inches (approx. 3.7 x 12.8 x 20.4 cm) |

| Manufacturer | The Tool Connection Ltd. |

8. Warranty and Support

For specific warranty information regarding your Laser 3568 Alldrive Socket & Bit Set, please refer to the documentation provided at the time of purchase or contact the manufacturer directly. Warranty terms and conditions may vary.

Manufacturer: The Tool Connection Ltd.

For product support, technical assistance, or inquiries about replacement parts, please contact the manufacturer or your authorized dealer. Keep your purchase receipt as proof of purchase for any warranty claims.