Compressor Protection

Compressor Protection

Module Technical Guide

ASM06690, ASM07681 Compressor Protection Module

| PRODUCT NAME REVISION LOG | |

| REVISION AND DATE | CHANGE |

| Rev. A, December 15, 2021 | Original |

| Rev. B, February 9, 2022 | Added wiring for On/Off Compressors |

| Rev. C, December 18, 2023 | Added replacement part, wiring, and LED descriptions, updated layout |

| Rev. D, June 21, 2024 | Updated Dimensions |

| Rev. E, August 14, 2024 | Updated Illustrations |

| PRODUCT NAME PARTS REFERENCE | |

| PART DESCRIPTION | PART NUMBER |

| Compressor Protection Module | ASM06690 / ASM07681 |

All manuals are also available for download from www.aaon.com/controlsmanuals.

AAON

2425 South Yukon Ave.

Tulsa, OK 74107-2728

www.aaon.com

Factory Technical Support Phone: 918-382-6450

AAON Controls Support: 866-918-1100

It is the intent of AAON to provide accurate and current product information. However, in the interest of product improvement, AAON reserves the right to change pricing, specifications, and/or design of its product without notice, obligation, or liability.

AAON P/N:G100690, Rev. E

© August 2024 AAON Inc. All rights reserved.

AAON® is a registered trademark of AAON, Inc., Tulsa, OK.

Copeland® is a registered trademark of Emerson Electric Co., St.

Louis, MO. OMNIMATE® is a registered trademark of Weidmüller, Detmold, Klingenbergstraße, Germany

AAON assumes no responsibility for errors or omissions in this document.

This document is subject to change without notice.

OVERVIEW

General Information

Overview

The Compressor Protection Module is used in split systems as a stand-alone module. It provides additional protection for compressors in systems with self-resetting pressure switches. The module uses high pressure and low pressure switches to disable the compressor and enforce a minimum compressor off time when a fault occurs. It also limits the number of retries and locks out the compressor if it exceeds the maximum number of allowed faults. The Compressor Protection Module sequence is intended to help with the start up of units with microchannel coils and prevent nuisance lockouts when the coil is cold.

The Compressor Protection Module supports up to two compressors.

There is no staging or fail over functionality within the module; the compressors operate independently.

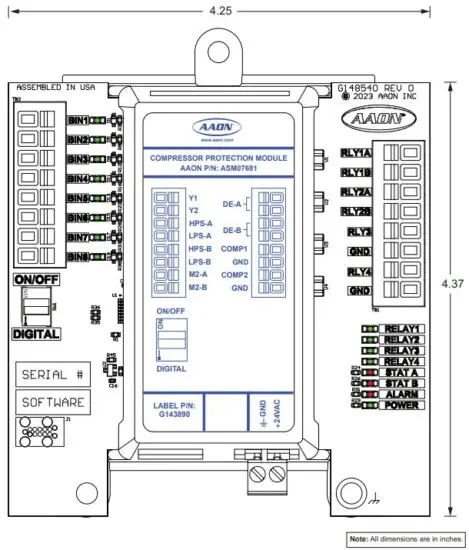

The ASM07681 is equipped with new OMNIMATE connectors for easier installation. See Figure 6, page 13.

Dimensions

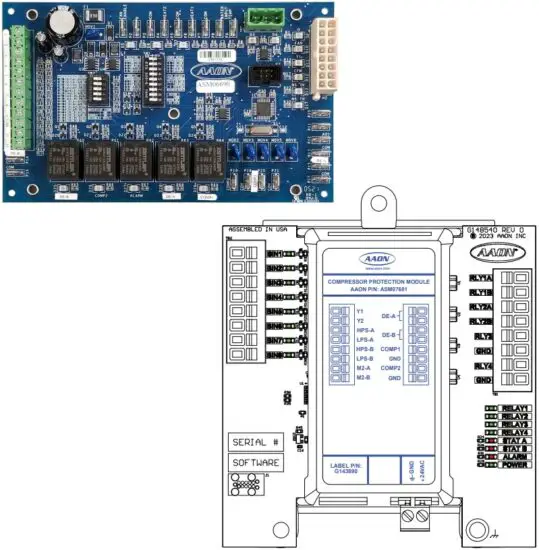

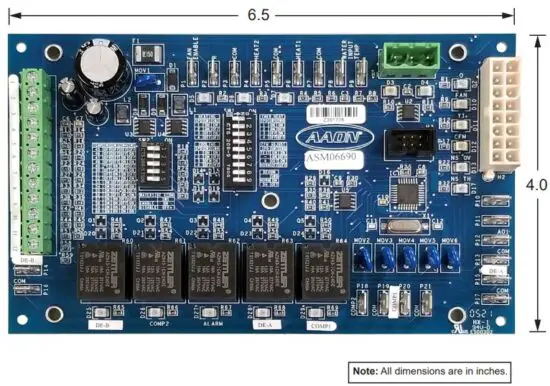

Figure 1: Compressor Protection Module Dimensions – ASM06690

Figure 1: Compressor Protection Module Dimensions – ASM06690

Figure 2: Compressor Protection Module Dimensions – ASM07681

Figure 2: Compressor Protection Module Dimensions – ASM07681

INSTALLATION AND WIRING

Wiring

Wiring Overview

In general, most Compressor Protection Modules are installed and wired at the AAON factory. Some of the following information pertains to field wiring and may not apply to your installation if it was pre-wired at the factory. However, if troubleshooting of the module is required, it is a good idea to be familiar with the system wiring, no matter if it was factory or field wired.

Mounting

When the Compressor Protection Module is field mounted, it is important to mount it in a location that is free from extreme high or low temperatures, moisture, dust, and dirt. See Table 1, this page, for a list of the required operating conditions for the Compressor Protection Module.

The Compressor Protection Module is designed to be mounted via the four shoulder eyelets located on the corners of each circuit board.

CAUTION: Be careful not to damage the electronic components when mounting the module.

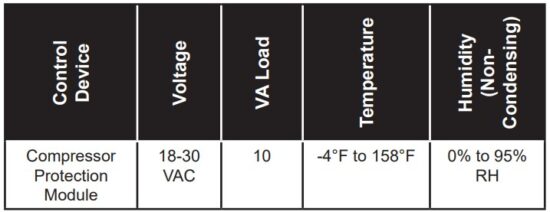

Electrical & Environmental Requirements

The Compressor Protection Module must be connected to a 24 VAC power source of the proper size for the calculated VA load requirements. All transformer sizing should be based on the VA rating listed in Table 1, this page.

Table 1: Compressor Protection Module Specifications

Table 1: Compressor Protection Module Specifications

Inputs and Outputs

I/O Map

See Table 2 and 3, this page, for Compressor Protection Module inputs and outputs.

| ASM06690 -Compressor Protection Module | |

| Inputs | |

| Pluggable Screw Terminal Block H4 | |

| 2 | Compressor A call from the main controller (Y1) |

| 3 | Compressor B call from the main controller (Y2) |

| 4 | High pressure switch for Compressor A (HPS-A) |

| 5 | Low pressure switch for Compressor A (LPS-A) |

| 6 | High pressure switch for Compressor B (HPS-B) |

| 7 | Low pressure switch for Compressor B (LPS-B) |

| 10 | Compressor A output from Copeland Controller (M2-A) |

| 11 | Compressor B output from Copeland Controller (M2-B) |

| 12 | Compressor control relay ground |

| Quick Disconnect Terminals | |

| P2-R | 24 VAC |

| P3-COM | Ground |

| Relays | |

| Quick Disconnect Terminals | |

| COMP1 | Compressor A 24 VAC output |

| COMP2 | Compressor B 24 VAC output |

| DE-A | Compressor A demand enable |

| DE-B | Compressor B demand enable |

| P21-COM | Compressor A ground |

| P19-COM | Compressor B ground |

Table 2: Inputs and Outputs – ASM06690

| Compressor Protection Module | |

| Inputs | |

| BIN1 | Compressor A call from the main controller (Y1) |

| BIN2 | Compressor B call from the main controller (Y2) |

| BIN3 | High pressure switch for Compressor A (HPS-A) |

| BIN4 | Low pressure switch for Compressor A (LPS-A) |

| BIN5 | High pressure switch for Compressor B (HPS-B) |

| BIN6 | Low pressure switch for Compressor B (LPS-B) |

| BIN7 | Compressor A output from Copeland Controller (M2-A) |

| BIN8 | Compressor B output from Copeland Controller (M2-B) |

| Relays | |

| RLY1A | DE-A (Compressor A demand enable) |

| RLY1B | RLY1 Common |

| RLY2A | DE-B (Compressor B demand enable) |

| RLY2B | RLY2 Common |

| RLY3 | COMP1 (Compressor A output) |

| GND | GROUND |

| RLY4 | COMP2 (Compressor B output) |

| GND | GROUND |

Table 3: Inputs and Outputs – ASM07681

Inputs and Outputs Descriptions

Compressor Protection Module I/Os

Compressor A call

This is the Compressor A call from the main controller.

Compressor B call

This is the Compressor B call from the main controller.

High pressure switch

This is the high pressure switch or compressor run status for Compressor A.

Low pressure switch

This is the low pressure switch for Compressor A.

High pressure switch

This is the high pressure switch or compressor run status for compressor B.

Low pressure switch

This is the low pressure switch for compressor B.

Compressor A output

This is the Compressor A output from the Copeland Controller.

Compressor B output

This is the Compressor B output from the Copeland Controller.

Compressor control relay ground (ASM06690 only)

This is the ground connection for the compressor control relay..

P2-R – 24 VAC input (ASM06690 only)

This is the 24 VAC input for the Compressor Protection Module.

Compressor A Output

This is the Compressor A 24 VAC output which energizes the compressor contactor.

Compressor A Enable

This is the Compressor A demand enable which energizes external relay to pass the demand VDC signal to Copeland Controller.

Compressor B Output

This is the Compressor B 24 VAC output which energizes the compressor contactor.

Compressor B Enable

This is the Compressor B demand enable which energizes the external relay to pass the demand VDC signal to the Copeland Controller.

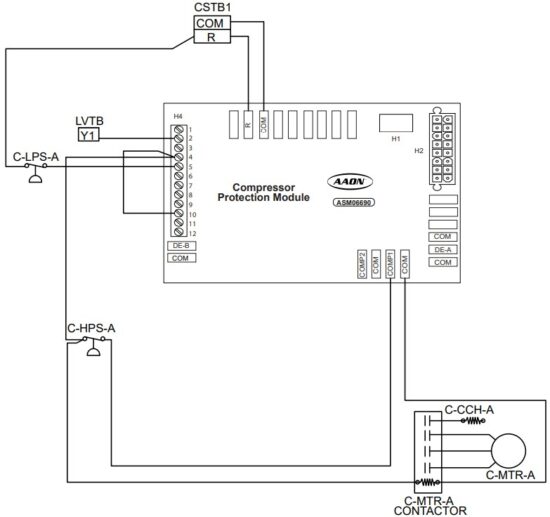

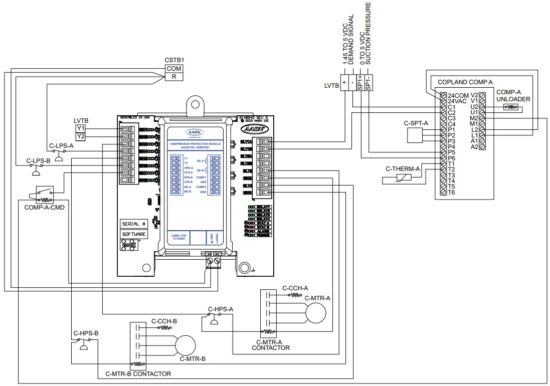

ASM06690 – Single Compressor

Figure 3: ASM06690 – Single Compressor

Figure 3: ASM06690 – Single Compressor

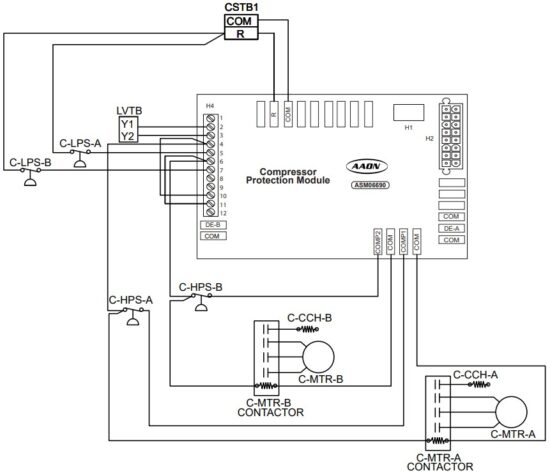

ASM06690 – Dual Compressor

Figure 4: ASM06690 – Dual Compressor

Figure 4: ASM06690 – Dual Compressor

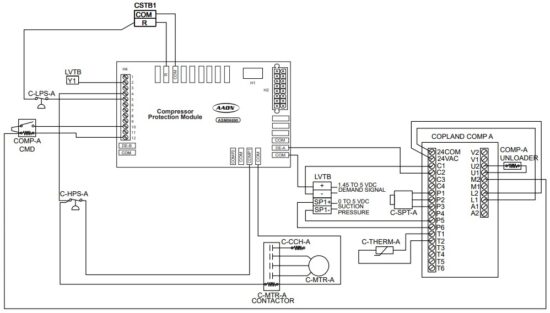

ASM06690 – Single Digital Compressor

Figure 5: ASM06690 – Single Digital Compressor

Figure 5: ASM06690 – Single Digital Compressor

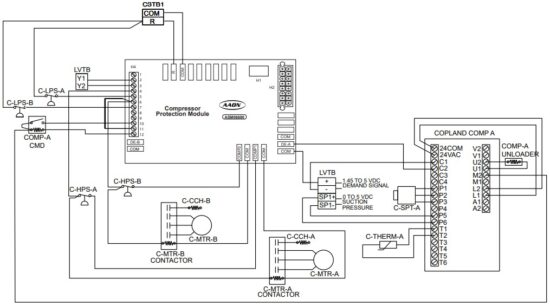

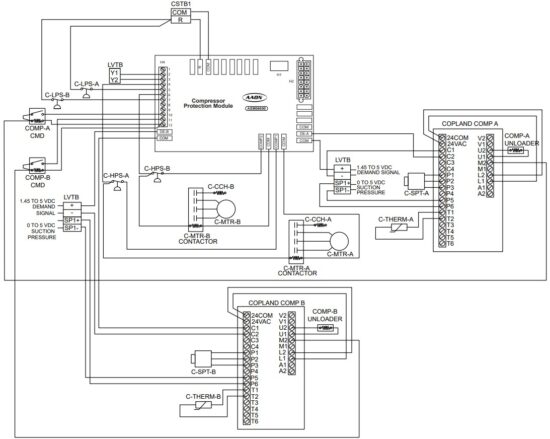

ASM06690 – Digital and On/Off Compressor

Figure 6: ASM06690 – Digital and On/Off Compressor

Figure 6: ASM06690 – Digital and On/Off Compressor

ASM06690 – Dual Digital Compressor

Figure 7: ASM06690 – Dual Digital Compressors

Figure 7: ASM06690 – Dual Digital Compressors

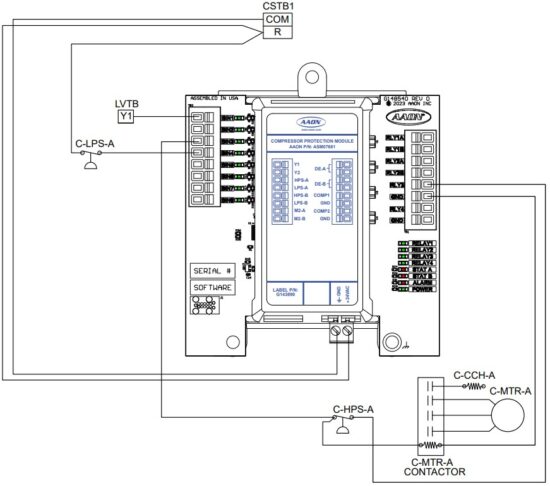

ASM07681 – Single Compressor

Figure 8: ASM07681 – Single Compressor

Figure 8: ASM07681 – Single Compressor

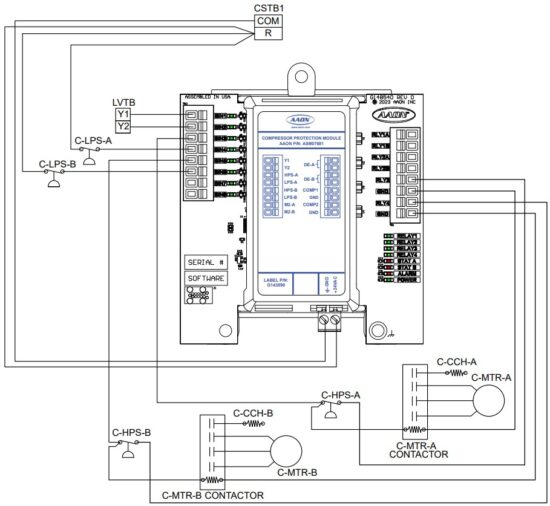

ASM07681 – Dual Compressor

Figure 9: ASM07681 – Dual Compressor

Figure 9: ASM07681 – Dual Compressor

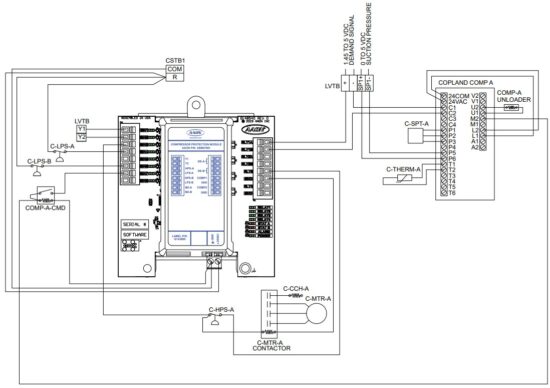

ASM07681 – Single Digital Compressor

Figure 10: ASM07681 – Single Digital Compressor

Figure 10: ASM07681 – Single Digital Compressor

ASM07681 – Digital and On/Off Compressor

Figure 11: ASM07681 – Digital and On/Off Compressor

Figure 11: ASM07681 – Digital and On/Off Compressor

ASM07681 – Dual Digital Compressors

Figure 12: ASM07681 – Dual Digital Compressors

Figure 12: ASM07681 – Dual Digital Compressors

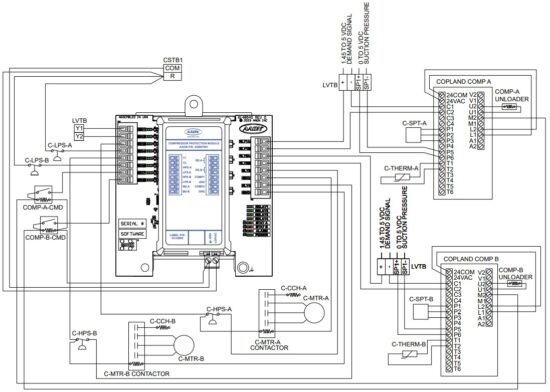

OMNIMATE® Connector – ASM07681 Only

Figure 13: OMNIMATE Connector Instructions

Figure 13: OMNIMATE Connector Instructions

SEQUENCE OF OPERATIONS

Operation Modes

Compressor Operation

The compressor operation is determined by the compressor call fromthe main controller and the compressor output from the Copeland Compressor Controller.

Sequence of Operation

Off

When the compressor call is not energized, the compressor relay output and demand enable will be de-energized.

Compressor Call Active

When the compressor call and the low pressure switch energize, the demand enable energizes, which allows the compressor demandsignal to pass from the main controller to the Copeland Controller.

NOTE: The compressor relay output will not energize if the low pressure switch is not energized. This could indicate a loss of charge in the system.

When the compressor output from the Copeland Controller is energized, the Compressor Protection Module will energize the compressor 24 VAC to energize the compressor output from the Copeland Controller. The low pressure switch and high pressure switch are ignored and will not trigger any alarms until the compressor output from the Copeland Controller is energized.

NOTE: This is to prevent false alarms on the Compressor Protection Module when the Copeland Controller is in its own minimum off time.

If the compressor output from the Copeland Controller is deenergized while the compressor call is still active, the Compressor Protection Module will de-energize the compressor 24 VAC, but keep the demand enable energized. The compressor 24 VAC will re-energize when the demand for the compressor rises above 10%. The off time in this case is enforced by the Copeland Controller.

When the compressor call de-energizes, the compressor 24 VAC and demand enable will de-energize and a minimum compressor off time of five minutes will be enforced. If the compressor call becomes re-energized, the compressor will not restart until the minimum off time has elapsed.

NOTE: There is no minimum on time enforced by the Compressor Protection Module.

High Pressure Alarm Sequence

If the high pressure switch is not energized within five seconds of the compressor output from the Copeland Controller being active or if the high pressure switch is de-energized while the compressor is running, a high pressure alarm will be triggered.

If an alarm occurs on startup or within the first 15 minutes of the compressor call, the module will allow four retries, and will lock out on the fifth fault.

If a fault occurs after the first 15 minutes of the compressor call, the module will allow one retry, and will lock out if another fault occurs within two hours.

The alarm will de-energize the compressor 24 VAC and demand enable for two minutes and then re-energize the demand enable.

The low pressure switch and high pressure switch will be ignored and not trigger an alarm until the compressor output from the Copeland Controller has re-energized. The compressor 24 VAC will energize once the compressor output from the Copeland Controller is energized.

The fault counter will reset to zero if the compressor call is removed or the compressor has run successfully for two hours since the last fault.

If the module is locked out, power to the module must be cycled to clear the lockout.

Operation Modes

Low Pressure Alarm Sequence

The Low Pressure Switch is ignored for one minute after the compressor contactor output becomes active.

NOTE: This alarm logic replaces a standalone timer-based low pressure switch bypass that defaults to five minutes. However, this five minutes is the default for the timer and has no relevance to the operation of the unit.

If the low pressure switch is de-energized for five seconds while the compressor is running, a low pressure alarm will be triggered and the compressor 24 VAC and demand enable will be de-energized.

If the compressor call is still active, the demand enable will be re-energized after five minutes. The low pressure switch and high pressure switch will be ignored and not trigger an alarm until the compressor output from the Copeland Controller has re-energized.

The compressor 24 VAC output will be energized once the compressor output from the Copeland Controller is energized.

The compressor will be locked out if three low pressure alarms occur within two hours.

If the compressor is locked out, power to the module must be cycled to clear the lockout.

TROUBLESHOOTING

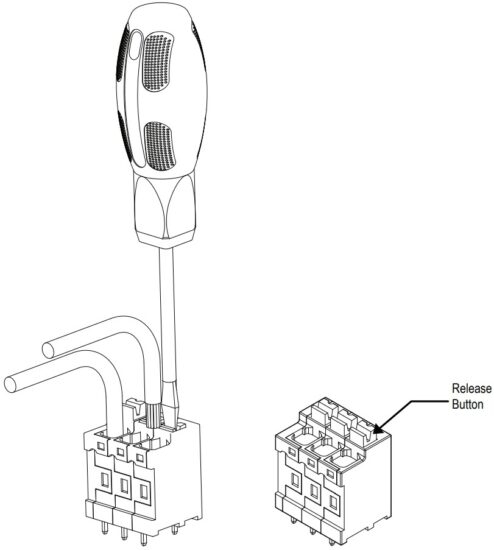

Compressor Protection Module LED Diagnostics

Compressor Protection Module LEDs

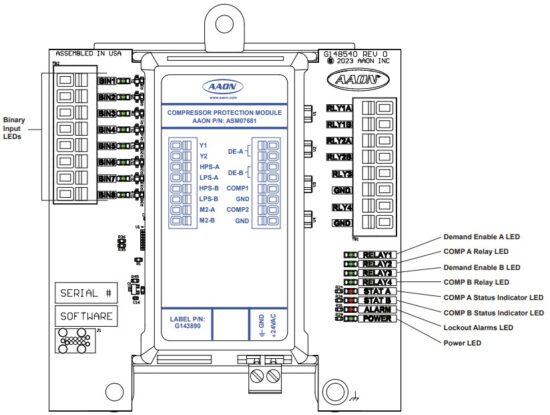

See Figure 3, page 14, for LED locations. The LEDs and their uses are as follows:

Operation LED

POWER – This green LED will light up when 24 VAC power is applied to the module.

Output LEDs

COMP A RELAY – This green LED will light up when Compressor A Relay is active.

COMP B RELAY – This green LED will light up when Compressor B Relay is active.

Demand Enable A – This green LED will light up when the demand enable for Compressor A is active.

Demand Enable B – This green LED will light up when the demand enable for Compressor B is active.

Controller Alarms

LED Fault Codes

The Compressor Protection Module has two status LEDs (D3 and D4) on the board to indicate faults for Compressor A and B. A green status light indicates the unit is powered up and that the module is not detecting any fault conditions. A flashing red status light indicates the module has detected a fault condition and is now in alarm mode. The number of flashes indicates what alarm is present. See Table 3, this page, for blink code descriptions.

Lockout Alarms

The Compressor Protection Module has an Alarm LED on the board to indicate when an alarm is present. This LED will light up red if there is an active High Pressure Lockout or Low Suction Lockout alarm for either compressor.

| COMP A and B Alarm Status Blinks | Blink Code Description |

| 0 | No Alarms |

| 1 | High Pressure Alarms |

| 2 | High Pressure Lockout |

| 3 | Low Suction Alarm |

| 4 | Low Suction Lockout |

Table 4: Alarm Status LED Diagnostic Codes

Compressor Protection Module LED Locations – ASM06690

Figure 14: LED Locations and Descriptions – ASM06690

Figure 14: LED Locations and Descriptions – ASM06690

Compressor Protection Module LED Locations – ASM07681

Figure 15: LED Locations and Descriptions – ASM07681

Figure 15: LED Locations and Descriptions – ASM07681

Compressor Protection Module Technical Guide

G100690 · Rev. E · 240814

AAON Controls Support: 866-918-1100

Monday through Friday, 7:00 AM to 5:00 PM

Central Standard Time

Controls Support website:

www.aaon.com/controlstechsupport

AAON Factory Technical Support: 918-382-6450

techsupport@aaon.com

NOTE: Before calling Technical Support, please have the model and serial number of the unit available.

PARTS: For replacement parts, please contact your local AAON Representative.

2425 South Yukon Ave • Tulsa, OK • 74107-2728

2425 South Yukon Ave • Tulsa, OK • 74107-2728

Ph: 918-583-2266 • Fax: 918-583-6094

AAON P/N: G100690, Rev. E

Printed in the USA • Copyright August 2024

• All Rights Reserved

Documents / Resources

| AAON ASM06690, ASM07681 Compressor Protection Module [pdf] User Guide ASM06690, ASM07681, ASM06690 ASM07681 Compressor Protection Module, ASM06690 ASM07681, Compressor Protection Module, Protection Module, Module |